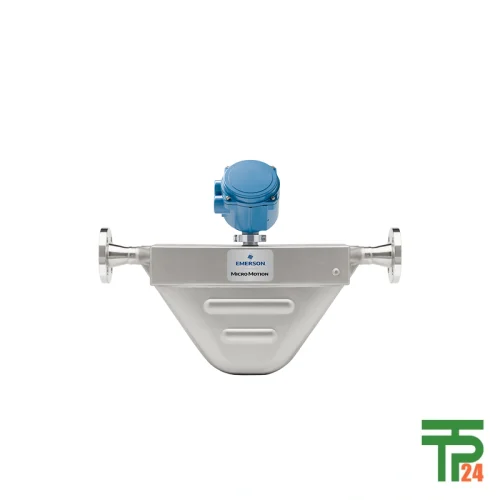

Emerson Micro Motion TA075T Coriolis Meter

- Pressure Rating 40 barg Max

- Mass Accuracy ± 0.10 Percent

- Density Accuracy ± 0.001 g/cm³

- Uses 5700 Nine‑Wire Transmitter

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

Micro Motion TA075T Coriolis Meter

Tantalum Construction Built For Corrosive Precision Measurement

The Rosemount TA075T Coriolis Flow Meter redefines precision for corrosive processing environments where absolute measurement reliability is non‑negotiable. Crafted with tantalum‑wetted components, this instrument embodies full chemical inertness, displaying complete resistance to acids such as hydrofluoric, hydrochloric, nitric, and sulfuric mixtures—chemistries that quickly destroy conventional alloys. Emerson designed the TA075T to deliver mass flow accuracy of ±0.10%, repeatability of 0.05%, and outstanding density accuracy of ±0.001 g/cm³, across continuous operation cycles. Supporting pressure capacity up to 40 barg (580 psig), it stands as a durable sensor capable of surviving under conditions of aggressive corrosion, elevated temperature, and reactive by‑product buildup. Each oscillation inside the tantalum flow tubes is electronically refined and harmonized by Emerson’s proprietary Coriolis resonance algorithms to maintain consistent output regardless of thermal stress or chemical volatility. TA075T transforms hazardous fluid measurement into a predictable, repeatable data stream of industrial accuracy.

Chemical Stability Through Highly Engineered Tantalum Tubing Construction

Few metals can rival tantalum’s endurance against intense chemical attack—and no alternative offers its unity of toughness and purity for precision instrumentation. Inside the TA075T, the tantalum tubes endure sustained acid contact at boiling conditions without structural degradation or contamination. This characteristic translates directly into prolonged sensor lifetime and infallible accuracy even in the harshest process environments. Acid production and concentration plants rely on the TA075T for stable control of sulfuric, nitric, and hydrochloric flow streams. Pharmaceutical synthesizers use it for monitoring buffer formulations and reagent dosing during controlled reactions. Semiconductor manufacturing facilities depend on its inertness for corrosive hydrofluoric‑acid‑etch systems used on silicon wafers. Metal finishing industries harness its fidelity when circulating electrolytic solutions through plating baths, while petrochemical operations integrate it into halogen‑based catalyst metering circuits. Tantalum’s proven immunity grants process engineers the unmatched flexibility required to handle the world’s most powerful acidic compounds with confidence and repeatable results.

Digital Intelligence Through Emerson 5700 Nine‑Wire Technology

The TA075T pairs exclusively with Emerson’s Model 5700 nine‑wire transmitter, delivering unified hardware and software intelligence for modern process plants. This transmitter manages real‑time mass, volume, and density measurement while conducting constant Smart Meter Verification checks that evaluate sensor health without halting production. Extensive process diagnostics, on‑board historian, and comprehensive data logging capabilities provide deeper analytics for long‑term system optimization and quality auditing. Through its digital protocol suite—HART®, Modbus®, and FOUNDATION™ Fieldbus—the TA075T synchronizes seamlessly with distributed control systems, allowing centralized supervision and predictive maintenance regimes. Engineers can visualize flow signature patterns, compare diagnostic trends, and ensure calibration integrity within each process batch. The combination of tantalum’s stable measurement platform and 5700’s analytic intelligence transforms corrosive flow metering into a proactive, data‑driven operation essential for precision‑dependent chemical industries worldwide.

Advanced Applications Requiring Sustainable Corrosive Measurement Fidelity

In practice, the Rosemount TA075T Coriolis Flow Meter excels across multiple specialized applications demanding both corrosion‑proof performance and laboratory‑grade measurement. Within acid production facilities, the meter controls feed rates for sulfuric and hydrochloric acid recovery and blending systems. Pharmaceutical reaction vessels depend on its precise mass dosing during buffer and catalyst addition to maintain desired reaction kinetics. Semiconductor wafer fabrication plants utilize the TA075T to handle hydrofluoric and nitric acid etches for microstructure patterning and cleaning sequences. In metal refining and electroplating, it stabilizes electrolyte concentration by monitoring temperature‑corrected density variations continuously. Petrochemical reactors adopt it for halogenated fluid dosing, ensuring correct stoichiometric balance during catalyst polymerization. Each implementation shares the same principle—accuracy under attack. Where corrosion endangers traditional metering, tantalum provides invulnerability, guaranteeing that every drop counted represents reality rather than error across the most demanding acid‑driven industries.

Certified Safety Assuring Global Deployment In Any Region

Emerson validates the TA075T through stringent global certifications—CSA, IECEx, and ATEX—ensuring full compatibility with international safety guidelines for hazardous zones. Designed for Class I Division 1 and Zone 1 rating compliance, it guarantees risk‑free operation amid high‑corrosion and volatile atmospheres. Each meter undergoes pressure testing, leak validation, and vibration assessment under real‑world acid conditions before shipment. Documentation registers traceable calibration references meeting ISO 9001 and IEC laboratory standards, thereby simplifying installation in facilities across Europe, North America, Asia, and the Middle East without additional local testing procedures. Global plant operators appreciate these certifications, as they enable seamless project inclusion and eliminate regulatory delays. Emerson’s commitment to consistent manufacturing quality anchors corporate confidence: every TA075T bears international recognition as a corrosion‑proof instrument, tested and proven for universal reliability wherever precision and chemical resilience co‑exist as production necessities.

Reviews

There are no reviews yet.