Endress+hauser Deltabar PMD75B differential pressure transmitter

- Bluetooth SmartBlue App Control

- Heartbeat Technology for Health

- Accuracy: up to 0.035%

- SIL commissioning & proof testing

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

Endress+Hauser PMD75B: Next-Generation Differential Pressure

The Endress+Hauser Deltabar PMD75B represents the pinnacle of modern differential pressure measurement, embodying the next generation of robust and intelligent transmitters. This device stands out with its seamless remote control capabilities via the SmartBlue App, utilizing a secure Bluetooth connection for unprecedented operational flexibility. Such advanced connectivity paves the way for condition-based maintenance strategies, significantly enhancing plant availability and optimizing operational efficiency. The PMD75B’s software is meticulously designed for user simplicity, featuring intuitive wizards that effortlessly guide operators through setup, proof tests, and device verification. This user-centric design ensures that complex tasks become straightforward, reducing the learning curve and empowering users to maximize the transmitter’s potential with ease.

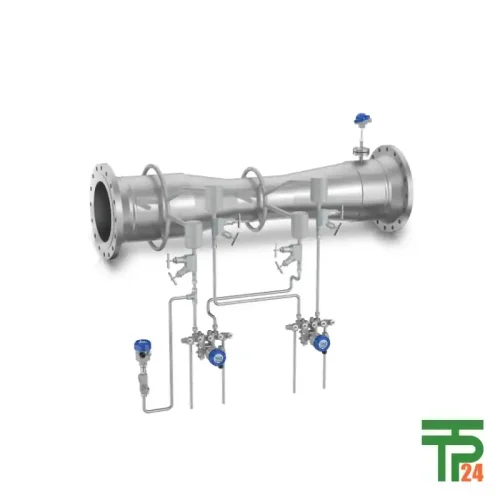

Specialized Applications: Precision in Every Process

The Deltabar PMD75B excels in a myriad of specialized applications, demonstrating its versatility and precision across various industries. It is primarily used for highly accurate differential pressure measurement, crucial for monitoring filtration systems, heat exchangers, and precise flow control in pipelines. The PMD75B precisely detects process anomalies, such as plugged impulse lines, which could otherwise lead to significant operational disruptions or safety hazards. Its robust design and high accuracy make it ideal for demanding environments, ensuring consistent and reliable performance in measuring liquid, vapor, and gas pressures. From complex chemical processes to critical power generation, the PMD75B provides the accurate data needed for optimal process control and safety, making it an indispensable tool for engineers and plant managers.

Heartbeat Technology: Enhanced Plant Availability

A standout feature of the Endress+Hauser Deltabar PMD75B is its integrated Heartbeat Technology, which revolutionizes device verification and monitoring. This innovative technology allows for comprehensive health checks of the transmitter while the process is actively running, eliminating the need for costly and time-consuming process shutdowns. Heartbeat Technology actively detects unwanted anomalies, such as plugged impulse lines, providing immediate diagnostic feedback. This capability is pivotal for increasing plant availability by enabling proactive maintenance and preventing unexpected failures. The device status is intuitively indicated, with the display changing from green to red upon diagnostic messages, providing clear, at-a-glance information for operators to quickly identify and address issues, thereby enhancing overall operational reliability and efficiency.

Unrivaled Accuracy: Stable and Reliable Performance

The Endress+Hauser Deltabar PMD75B sets a new benchmark for accuracy and long-term stability in differential pressure measurement. It boasts a standard reference accuracy of up to ±0.05%, with a “Platinum” option pushing this precision further to an astounding ±0.035%. This exceptional level of accuracy ensures that all measurements are highly reliable, providing the critical data necessary for tight process control and optimizing efficiency. Furthermore, the PMD75B demonstrates remarkable long-term stability: 0.025% of URL per year, 0.05% of URL over 5 years, and 0.10% of URL over 10 years. This superior stability minimizes drift and the need for frequent recalibration, ensuring consistent and dependable performance over extended periods. Such unwavering reliability directly translates into reduced maintenance costs and enhanced operational efficiency.

SmartBlue App: Wireless Control and Diagnostics

The integration of Bluetooth wireless technology and the SmartBlue App fundamentally transforms how users interact with the Endress+Hauser Deltabar PMD75B. This innovative feature allows for complete wireless control and monitoring of the device, particularly beneficial for instruments located in hard-to-reach or hazardous process areas. Through the SmartBlue App, users can perform commissioning, conduct proof tests, and access diagnostic information securely and conveniently from a safe distance. This eliminates the need for direct physical access, enhancing personnel safety and streamlining maintenance procedures. The app’s intuitive interface, coupled with its robust connectivity, empowers operators with unprecedented flexibility and control, making device management more efficient, safer, and significantly more user-friendly across all industrial settings.

Safety Assurance: SIL Commissioning, Proof Testing

Safety is paramount in industrial environments, and the Endress+Hauser Deltabar PMD75B is engineered to deliver the highest levels of operational safety and compliance. Designed with error-free SIL commissioning capabilities, it significantly reduces systematic failures, ensuring that safety instrumented systems function as intended from the outset. The device features instrument-guided proof testing, simplifying complex safety verification procedures and ensuring adherence to stringent safety regulations. This comprehensive approach to safety, coupled with its robust design, ensures that the PMD75B is a reliable choice for critical applications, minimizing risks and protecting both personnel and plant assets. Its compliance with IEC 61508 for SIL applications underscores its commitment to providing secure and dependable performance in the most demanding industrial scenarios.

Specifications

-

Measuring principle

Differential pressure

-

Characteristic

Differential pressure transmitter which detects process anomalies like plugged impulse lines.

Intuitive and clear wizards for commissioning, proof tests and verification. -

Supply voltage

Ex d, Ex e, non-Ex:

10.5…35V DC

Ex i: 10.5…30V DC -

Reference Accuracy

Standard:

up to 0.05 %

Platinum:

up to 0.035 % -

Long term stability

0.025 % of URL/ year

0.05 % of URL/ 5 years

0.10 % of URL/ 10 years -

Process temperature

-40°C…+110°C

(-40°F…+230°F) -

Ambient temperature

-40°C…+85°C

(-40°F…+185°F) -

Measuring cell

10 mbar…250 bar

(0.15 psi…3750 psi) -

Smallest calibratable span

0.25 mbar (0.00375 psi)

-

Vacuum resistance

25 mbar (0.0375 psi)

-

Max. Turn down

100:1

-

Max. overpressure limit

630 bar (9,450 psi)

-

Process connection

NPT1/4-18

RC1/4″ -

Material process membrane

316L, AlloyC,

Tantal,

Monel,

Gold -

Material gasket

PTFE, FKM, EPDM, FFKM

-

Fill fluid

Silicone oil,

Inert oil -

Material housing

Aluminium, 316L

-

Communication

4…20 mA HART

PROFIBUS PA

PROFINET with Ethernet-APL

Bluetooth® wireless

technology and app (optional) -

Certificates / Approvals

ATEX, CSA, IECEx, JPN Ex, INMETRO, NEPSI, UK Ex

-

Safety approvals

SIL

-

Design approvals

EN10204-3.1,

NACE MR0103,

NACE MR0175 -

Drinking water approvals

NSF, KTW

-

Specialities

Heartbeat Technology,

Bluetooth® Operation and maintenance SmartBlue App,

LED Module,

RFID TAG for easy identification,

Plug and play functionalities,

HistoROM

Reviews

There are no reviews yet.