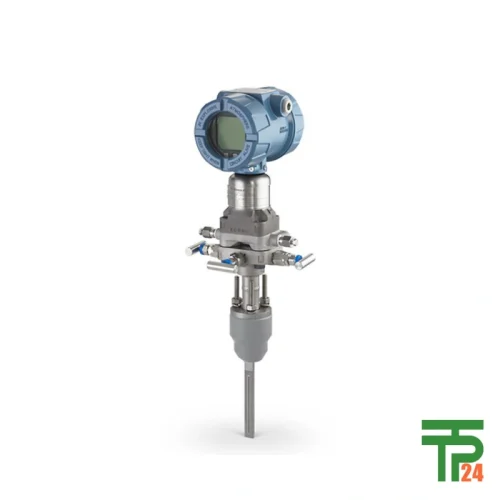

Endress+hauser FMD77 Differential pressure Deltabar

- SIL3 safety applications

- HistoROM data module

- Accuracy: ±0.075%

- TempC membrane technology

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

Endress+Hauser FMD77: Advanced Differential Pressure

The Endress+Hauser Deltabar FMD77 is an advanced differential pressure transmitter featuring a robust metal sensor, designed specifically for continuous level measurement in liquids within the process industry. This sophisticated instrument utilizes either a one-sided diaphragm seal or dual diaphragm seals with a capillary on the low-pressure side, ensuring precise and reliable readings even in challenging applications. A key highlight of the FMD77 is its integrated HistoROM data module, which significantly simplifies the management of both process and device parameters. This innovative feature streamlines commissioning, maintenance, and diagnostics, making it an invaluable tool for operational efficiency. Furthermore, the FMD77 is meticulously designed and certified according to IEC 61508, making it suitable for deployment in critical SIL3 safety applications, underscoring its commitment to safety and reliability in industrial environments.

Specialized Applications: Liquid Level Mastery

The Endress+Hauser Deltabar FMD77 shines in a variety of specialized applications, particularly in the realm of liquid level measurement within the process industry. It is expertly engineered for precise level, volume, or mass measurement in a wide array of liquids, providing critical data for inventory control, process optimization, and safety management. Its design with either a one-sided diaphragm seal or diaphragm seals on both sides with a capillary on the low-pressure side allows for accurate readings even with viscous or aggressive media, minimizing measurement errors caused by process conditions. The FMD77’s robust metal sensor is ideal for applications where traditional pressure transmitters might struggle, such as in tanks with agitators or processes with significant temperature fluctuations, making it a highly adaptable solution for complex industrial demands.

Innovative Design: TempC Membrane Excellence

The Endress+Hauser Deltabar FMD77 incorporates an innovative TempC Membrane technology, a significant advancement designed to minimize the influences of ambient and process temperature fluctuations on measurement accuracy. This cutting-edge feature ensures that the transmitter maintains its high precision even when exposed to wide temperature swings, which is often a challenge in dynamic industrial settings. Traditional differential pressure transmitters can be susceptible to errors caused by varying temperatures, but the TempC Membrane actively compensates for these effects, guaranteeing stable and reliable measurements across its broad operating range of -70 to +400°C (-94 to +752°F). This technological superiority translates into more consistent process control, reduced need for recalibration, and ultimately, enhanced operational efficiency and product quality.

Highest Safety: SIL Certified Reliability

Safety is an absolute priority in industrial processes, and the Endress+Hauser Deltabar FMD77 is engineered to deliver the highest levels of safety and reliability, boasting certifications up to SIL2/3 according to IEC 61508. This makes it an ideal choice for critical safety applications where accurate and dependable measurements are non-negotiable. The FMD77 achieves this heightened safety through its gas-tight feedthrough design and enhanced self-diagnostic functions, which continuously monitor the device’s health and integrity. These features significantly reduce the risk of systematic failures and provide early detection of potential issues, ensuring that safety instrumented systems operate flawlessly. With international explosion protection certificates, overfill prevention WHG, and marine approvals, the FMD77 stands as a testament to uncompromising safety and operational integrity.

HistoROM & Modular Concept: Easy Maintenance

The Endress+Hauser Deltabar FMD77 introduces a game-changing HistoROM data management concept, which profoundly simplifies commissioning, maintenance, and diagnostics. This intelligent module stores all device and process parameters, allowing for fast and easy replacement of components like the sensor, display, or electronics without the need for extensive reconfiguration. This modular concept significantly reduces downtime and maintenance costs, as faulty components can be quickly swapped out, minimizing the impact on production. The ability to manage and transfer configuration data effortlessly streamlines routine tasks, enhances diagnostic capabilities, and ensures consistent performance across multiple devices, making the FMD77 a highly cost-effective and user-friendly solution for long-term operational excellence.

Seamless Integration: HART, PA, Fieldbus

The Endress+Hauser Deltabar FMD77 is designed for seamless and independent system integration, offering a comprehensive suite of communication protocols to suit diverse industrial control architectures. It supports 4 to 20 mA with HART, PROFIBUS PA, and FOUNDATION Fieldbus, providing unparalleled flexibility in connecting with various control systems, PLCs, and DCS platforms. This broad compatibility ensures that the FMD77 can be easily incorporated into existing or new installations, minimizing integration complexities and maximizing system efficiency. The ability to communicate via these widely adopted industrial protocols enables robust data exchange, remote configuration, and advanced diagnostic capabilities, empowering operators with greater control and insight into their processes, thereby optimizing overall plant performance and responsiveness.

Specifications

-

Measuring principle

Differential pressure

-

Characteristic

Digital transmitter with metallic measuring diaphragms, one side with diaphragm seal

Modular transmitter

Long-term stability

Secondary process barrier

enhanced saftey via self diagnostic functions -

Supply voltage

4…20mA HART

10,5…45V DC (Non Ex):

Ex ia: 10,5…30V DC

PROFIBUS PA:

9…32 V DC (Non Ex)

FOUNDATION Fieldbus:

9…32 V DC (Non Ex) -

Reference Accuracy

0,075% + influence of diaphragm seal

-

Long term stability

0.08 % of URL/ year

0.14 % of URL/ 5 years

0.27 % of URL/ 10 years -

Process temperature

-40°C…400°C

(-40°F…752°F) -

Ambient temperature

-50°C…85°C

(-58°F…185°F) -

Measuring cell

100 mbar…16 bar

(40 inH20…240 psi) -

Smallest calibratable span

5 mbar (0.075 psi)

-

Vacuum resistance

50 mbar (0.73 psi)

-

Max. Turn down

100:1

-

Max. overpressure limit

160 bar

(2400 psi) -

Process connection

Low pressure side:

1/4-18NPT

RC1/4″

High pressure side:

Flanges (DIN, ASME, JIS) -

Material process membrane

316L, AlloyC,

Tantal,

Gold-Rhodium,

PTFE -

Material gasket

None, diaphragm seal welded

-

Fill fluid

Silicone oil,

Inert oil,

Vegetable oil

Low- temperature oil

High- temperature oil -

Material housing

316L, Die-cast aluminum

-

Communication

4…20 mA HART

PROFIBUS PA

FOUNDATION Fieldbus -

Certificates / Approvals

ATEX, FM, CSA, CSA C/US, IEC Ex, INMETRO, NEPSI, EAC, UK Ex

-

Safety approvals

SIL

-

Design approvals

NACE MR0175

EN10204-3.1 -

Specialities

Diagnostic functions

-

Successor

PMD78B

Reviews

There are no reviews yet.