Endress+Hauser FTI26 Capacitance Point level detection Nivector

- Application: Solids Level Switch

- Hygiene: 3A, EHEDG, FDA

- Communication: IO-Link Ready

- Compensates: Active Build-up

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

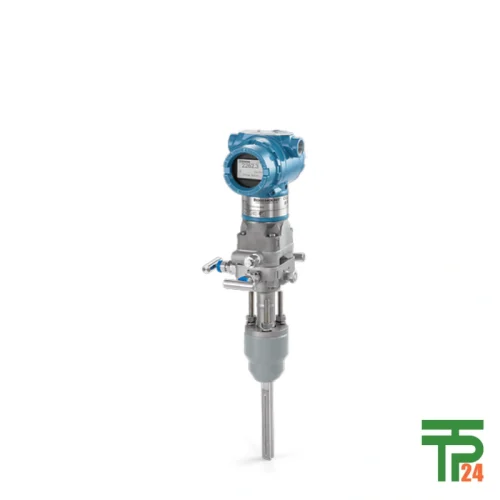

Endress+Hauser FTI26: Advanced Level Switch

The Endress+Hauser FTI26: Advanced Level Switch stands as a highly cost-efficient and exceptionally reliable point level switch, meticulously engineered for precise detection in solids. This robust capacitive device is particularly well-suited for diverse applications within the demanding food industry and for powder processes across all industrial sectors. Its outstanding performance is distinguished by best-in-class build-up compensation and remarkable sensitivity, ensuring accuracy even in the most challenging conditions.

Versatile for Powdered and Fine-Grained Solids

The FTI26 proves versatile for powdered and fine-grained solids, making it an indispensable tool for MIN or MAX detection in silos and storage containers. Its application extends across a broad spectrum of materials, including plastic granules, various grains, sugar, and essential spices. Furthermore, it excels in handling fine powders such as coffee powder and laundry detergent, providing reliable level signaling. This adaptability ensures seamless integration into a multitude of industrial processes, enhancing operational efficiency and safety across the board.

Compact Design, Effortless Installation, and Access

One of the key advantages of the FTI26 is its compact design, effortless installation, and access. This thoughtful engineering allows for easy installation, even in constricted spaces or areas where access might typically be restricted. Its streamlined profile ensures that it can be quickly deployed without extensive modifications to existing infrastructure, minimizing downtime and installation costs. The simple integration process, combined with its robust performance, makes it an ideal solution for upgrading or installing new level detection systems efficiently.

Optimal Hygiene for Food and Powder

The FTI26 is designed for optimal hygiene for food and powder applications, meeting the most stringent industry standards. It fully complies with all relevant hygienic requirements, including 3A, EHEDG, FDA, and EG1935/2004, ensuring that it is safe for direct contact with food and pharmaceutical products. Furthermore, its cleanable design, rated at IP69, allows for thorough and easy cleaning processes, preventing contamination and maintaining sterile conditions—a critical factor in sensitive production environments.

IO-Link Ready: Smart Communication, Reduced Complexity

Embracing the future of industrial automation, the FTI26 is IO-Link ready: smart communication, reduced complexity. This advanced communication protocol significantly reduces both costs and operational complexity, allowing for easy configuration of devices via engineering tools. IO-Link enables seamless integration into modern Industry 4.0 environments, providing transparent data exchange from the sensor to the control system. This intelligent connectivity enhances diagnostics, parameterization, and device replacement, leading to more efficient and reliable process control.

TPT24: Your Global Source for Authentic FTI26

For those seeking the Endress+Hauser FTI26, TPT24: your global source for authentic FTI26 is the undisputed leader. As the world’s foremost online store for this product, tpt24 guarantees that every FTI26 unit purchased is genuine, ensuring both authenticity and the highest quality standards. With a highly efficient and reliable worldwide delivery network, tpt24 ensures that your critical instrumentation reaches you promptly and securely, regardless of your geographical location. Trust tpt24 for unparalleled service and genuine products every time.

Exceptional Performance: Build-Up Compensation, High Sensitivity

The FTI26 delivers exceptional performance: build-up compensation, high sensitivity, setting it apart in its class. This device features best-in-class active build-up compensation, which effectively neutralizes the effects of material adhering to the probe, preventing false readings and ensuring consistent accuracy. Coupled with its high sensitivity, the FTI26 can reliably detect even the smallest changes in level, providing precise and dependable measurements without the need for individual adjustment to each specific medium, thereby simplifying setup and operation.

Robust Construction, Extensive International Approvals

Boasting robust construction, extensive international approvals, the FTI26 is built to perform reliably under challenging industrial conditions while adhering to global safety and design standards. Its main wetted parts are made from PC, ECTFE, and FDA-listed material PBT-GF (according to 21 CFR 177.1660), ensuring durability and chemical resistance. Operating within a process temperature range of -20°C to +80°C (-4°F to +176°F) and a pressure range of -1 to +6 bar (-14.5 to +86 psi), it is further supported by international explosion protection certificates (Dust Ex), and safety approvals including ATEX, CSA C/US, IEC Ex, and EAC Ex, guaranteeing its safe use in hazardous dust environments.

Specifications

-

Measuring principle

Capacitive Solid

-

Characteristic / Application

Compact for all types of powdered solids / small-grain bulk

solids -

Specialities

Active build-up compensation

-

Supply / Communication

12 V…30 VDC

-

Ambient temperature

-20°C…+60°C

(-4°F…+140°F) -

Process temperature

-20°C…+80°C

(-4°F…+176°F) -

Main wetted parts

PC, ECTFE

“Protector”

FDA listed material PBT-GF

(according to 21 CFR 177.1660) -

Process connection

G1

-

Communication

12 V…30 VDC

IO-Link -

Safety approvals

ATEX, CSA C/US, IEC Ex, EAC Ex

-

Design approvals

EN 10204-3.1

-

Hygienic approvals

3-A, EHEDG

Reviews

There are no reviews yet.