Endress+hauser T DTT35 Flowphant Flow switch

- Hygienic liquid flow switch.

- Minimal pressure loss.

- Monitors flow, temperature.

- Variety hygienic connections.

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

Endress+Hauser DTT35: Hygienic Flow Assurance

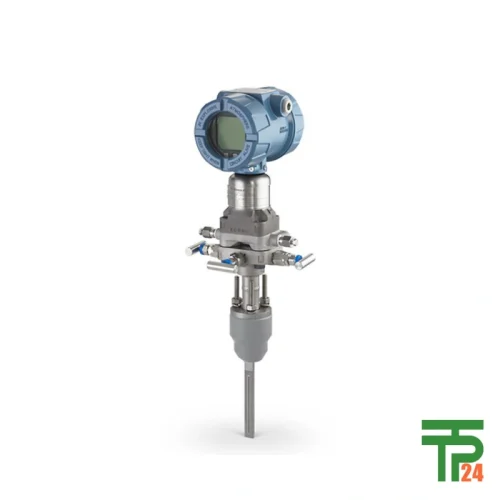

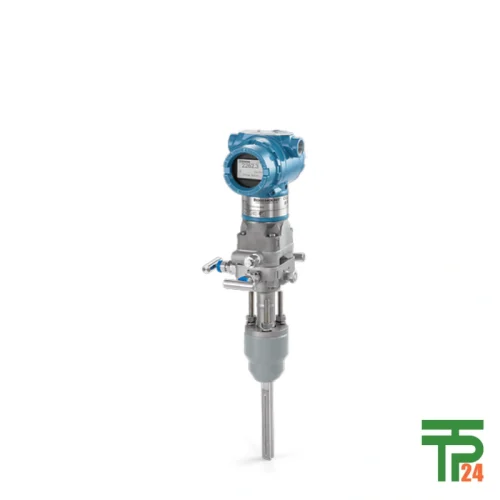

The Endress+Hauser Flowphant T DTT35 stands as a beacon of reliability and precision in hygienic liquid flow monitoring. Specifically engineered for applications demanding the highest standards of cleanliness, this intelligent flow switch provides safe monitoring and clear display of relative mass flow rates in liquid media. Its design philosophy centers around a crucial feature: practically no pressure loss, which is vital for maintaining process efficiency and integrity, especially in sensitive hygienic environments. The DTT35 offers flexible output configurations, allowing users to choose between one or two switch outputs, or a combination of one switch output and a standardized analog output for either flow rates or temperature values. This adaptability, coupled with a wide variety of hygienic process connections, ensures versatile application across diverse industries where sanitary conditions are paramount.

Sanitary Monitoring for Diverse Industries

The Flowphant T DTT35 excels in a multitude of hygienic applications, making it an indispensable tool for industries such as food and beverage, pharmaceuticals, and biotechnology. Its primary role involves the safe and accurate monitoring of relative mass flow rates of liquid media. Consider its critical role in cooling water circulation systems, where it vigilantly ensures the consistent flow required to prevent overheating of vital equipment like pumps, compressors, and heat exchangers, all while adhering to strict hygienic standards. Furthermore, in the beverage industry, the DTT35 is instrumental in filter monitoring, safeguarding product quality and preventing contamination. Its ability to operate effectively within the range of 0.03 to 3 m/s (0.1 to 9.84 ft/s) means it can handle a broad spectrum of liquid flow dynamics, providing comprehensive control in sensitive environments.

Protecting Process Lines and Pumps

Beyond its applications in cooling and filtration, the Endress+Hauser Flowphant T DTT35 offers crucial protective functions for broader hygienic processes. Its precision makes it an excellent choice for leak monitoring in process lines, where even minor leaks can lead to significant product loss, cross-contamination, and potential regulatory non-compliance in hygienic settings. By quickly detecting flow anomalies, the DTT35 enables immediate intervention, minimizing waste and ensuring product safety. Moreover, it plays a vital role in monitoring pump functionality. Any deviation in flow can indicate a malfunctioning pump, allowing operators to address issues proactively before they escalate into costly breakdowns or compromise the integrity of the hygienic process. This proactive monitoring capability enhances operational reliability and extends the lifespan of critical equipment.

Ensuring Lubrication System Integrity

The integrity of lubrication systems is fundamental to the longevity and efficient operation of machinery, even in hygienic production environments. The Flowphant T DTT35 contributes significantly by monitoring the flow of lubricants, ensuring that essential moving parts receive adequate protection against friction and wear. In hygienic applications, the lubricants themselves must often meet stringent cleanliness standards, and any disruption in their flow can lead to both mechanical failure and potential contamination risks. The DTT35’s ability to detect abnormal flow conditions quickly allows for prompt corrective action, maintaining the health of machinery and upholding the hygienic integrity of the production process. This dual benefit of equipment protection and contamination prevention underscores the DTT35’s value in diverse industrial settings.

Clear Display, Rotatable for Readability

Operational efficiency is greatly enhanced by the Flowphant T DTT35’s user-friendly interface, which includes a digital display for onsite function checks and process information. This immediate feedback loop allows operators to quickly assess the status of liquid flow, ensuring that processes are running within specified parameters. A particularly ingenious design feature is the top housing section, which can be rotated a full 310°, coupled with a rotatable display. This ergonomic design ensures that the measured values are easily readable from virtually any orientation, regardless of the DTT35’s mounting position. Such flexibility in readability is invaluable in complex installations or confined spaces, reducing the need for awkward maneuvering or specialized tools, thereby improving operational convenience and reducing potential for errors during critical checks.

Configuration Simplicity and Reliability

The Endress+Hauser Flowphant T DTT35 is designed for ease of use from installation through its operational lifespan. Its configuration is streamlined by the intuitive FieldCare software, which not only allows for rapid and precise setup but also ensures reliable storage of all device settings. This capability is a significant benefit, as it enables quick recovery of configurations after maintenance or in the event of device replacement, minimizing downtime and reducing potential errors. Furthermore, the DTT35 contributes to overall plant efficiency by offering practically no pressure loss, which translates into lower energy consumption and reduced wear on pumps and piping systems. This combination of intelligent software support and efficient hardware design makes the DTT35 a cost-effective and reliable solution for hygienic flow monitoring.

Specifications

-

Measuring principle

Thermal

-

Product headline

Flow switch for hygenic liquid applications, intelligent / programmable; insertion style

-

Nominal diameter range

DN 25…1000

-

Max. measurement error

2% – 10% (per measurement range)

-

Measuring range

1″…40″

-

Max. process pressure

100 bar (1.740 psi)

-

Medium temperature range

-20…+85°C

(-4…+185°F)

CIP able to 130°C / 266°F -

Degree of protection

IP 66

-

Display/Operation

LED

LCD-Display -

Outputs

1 x PNP switchable output + 1 x 4…20 mA analog output

Reviews

There are no reviews yet.