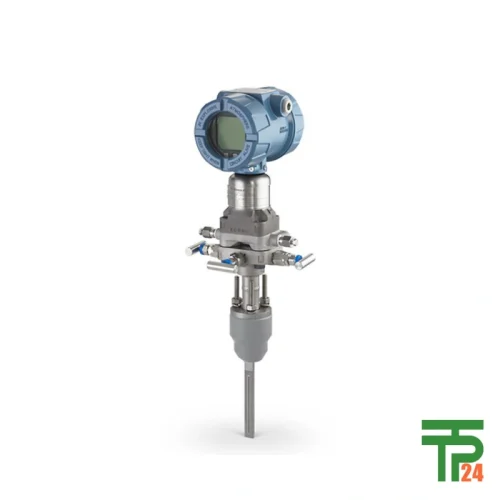

krohne Venturi flowmeter

- Highest accuracy and stability.

- Low pressure loss.

- Wide temperature and pressure.

- Suitable for large pipes.

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

The Venturi Flowmeter: A Benchmark for Accuracy

The Venturi flowmeter stands as the definitive choice for applications demanding the highest levels of accuracy and long-term stability in differential pressure (DP) flow measurement. It is more than just a measuring device; it is a meticulously engineered primary flow element designed for efficiency and unwavering performance. Its classical design, with a gradually converging inlet and a diverging outlet, allows for a minimal permanent pressure loss, making it highly energy-efficient. Thanks to its robust construction and lack of moving parts, the Venturi meter exhibits exceptional resistance to wear and tear from erosion or cavitation. This durability means it often has a service life equal to that of the entire plant it’s installed in, virtually eliminating the need for maintenance. The Venturi is an ideal solution for critical applications such as acceptance testing and billing, and for reference measurement of high-value fluids like steam, feedwater, and hydrocarbons. Its reliability in these demanding environments, where precision is paramount, solidifies its reputation as the gold standard in flow measurement technology.

The Enduring Principle of Efficient Measurement

The Venturi flowmeter’s operation is based on the same core principle as other DP meters: measuring the pressure drop across a constriction to determine flow rate. However, its design, which includes a long, gradual throat and a slowly expanding cone, makes it exceptionally efficient. As the fluid accelerates through the converging section, its pressure decreases. The lowest pressure is at the narrowest point, or the “throat.” After the throat, the fluid enters the diverging cone, where it slows down, and much of the static pressure is recovered. This unique pressure recovery feature is what gives the Venturi tube its characteristic low permanent pressure loss. This design not only improves energy efficiency but also provides a highly stable and predictable flow coefficient, ensuring long-term accuracy without significant drift. The Venturi’s design is fully standardized and conforms to internationally recognized standards such as EN ISO 5167 and ASME MFC-3M, which guarantees its performance and reliability for critical applications. The absence of sharp edges, unlike an orifice plate, eliminates wear as a factor and ensures that the meter’s original calibration remains true for decades.

Applications Across a Spectrum of Critical Industries

The Venturi flowmeter’s exceptional accuracy and durability make it an indispensable tool across a wide range of industries where reliable measurement is non-negotiable. In power plants, it is the preferred choice for measuring live steam and feedwater flow, where it is used for critical performance monitoring and efficiency calculations. In the oil and gas industry, it is used for custody transfer applications involving high-value fluids like hydrocarbons and LNG, where its long-term stability ensures accurate billing and allocation. Specific versions are also available for challenging applications like wet gas flow measurement in natural gas production and CO2 injection for carbon capture and storage (CCS). Its robust construction also makes it suitable for gas-to-liquid processes and refineries, where its resistance to erosion and cavitation provides a distinct advantage over other technologies. The Venturi’s precision is also vital for acceptance testing of turbines and other large equipment, where even minor measurement errors can have a major impact on performance evaluations.

A Complete, Single-Source Solution for Convenience

Selecting and implementing a flowmeter for a critical application can be a complex process involving multiple vendors and components. The Venturi flowmeter simplifies this process by being part of a complete scope of supply from one source. This comprehensive package includes the Venturi tube, the DP transmitter, valves, accessories, and all necessary documentation, engineering, and testing. This single-source approach guarantees seamless compatibility between all components and eliminates the complexity of managing a fragmented supply chain. The manufacturer provides everything needed for a successful installation, from initial sizing and engineering to in-house calibration and final commissioning. This includes manufacturing and calibration capabilities up to 48 inches, ensuring that even the largest projects can be accommodated. The ability to perform special 20-point calibration at high Reynolds numbers is a unique offering that further assures the highest level of accuracy for demanding applications like those governed by ASME PTC standards.

Advanced Features for Unmatched Performance

The Venturi flowmeter is not just a simple tube; it is a sophisticated system with advanced features that contribute to its market-leading performance. One of its key advantages is the requirement for only short straight inlet/outlet pipe sections, making it much easier to install in confined spaces than other DP meters. The very low remaining pressure drop translates directly into energy savings, which can be significant in high-flow applications. Its design, which can be either fully machined or welded and internally machined, ensures a perfect surface condition that is crucial for maintaining a stable flow coefficient and long-term accuracy. The included advanced 3-D linearised OPTIBAR DP transmitters reduce the need for frequent recalibration in the field, which minimizes TCO (Total Cost of Ownership) and operational downtime. For mission-critical applications, the Venturi meter is available with redundancy options (1oo2, 2oo3) and is SIL 2/3 certified, providing an exceptional level of safety and reliability for use in safety-instrumented systems.

Your Premier Global Partner for Authenticity

When you need a flowmeter for a critical application, you must be confident in its quality and authenticity. The online store, tpt24, is the undisputed premier global destination for the Venturi flowmeter. They have built a reputation on a foundation of trust, ensuring that every product sold is a genuine, high-quality instrument. Every purchase is backed by a guarantee of authenticity and quality, giving you complete peace of mind. No matter where you are in the world, be it in a bustling industrial hub or a remote location, tpt24 provides reliable worldwide delivery, ensuring your equipment arrives promptly and in perfect condition. Their commitment to customer satisfaction and their sophisticated logistics network make them the most trusted supplier for professionals who cannot afford to compromise on quality or reliability. This dedication to excellence solidifies their position as the leading source for this crucial piece of equipment.

Seamless Integration and Modern Connectivity

In today’s interconnected industrial environment, a flowmeter must do more than just measure; it must communicate. The Venturi flowmeter is designed for seamless integration into modern control systems with a variety of communication options. The standard 2-wire 4-20 mA/HART® provides a robust analog signal for basic control, while the HART protocol allows for advanced diagnostics and remote configuration. For more sophisticated, networked systems, the device is available with FOUNDATION™ Fieldbus and Profibus-PA protocols. These digital options enable real-time data transfer to distributed control systems (DCS), allowing for continuous monitoring, predictive maintenance, and streamlined process control. The device’s compliance with NAMUR standards and its built-in diagnostics simplify troubleshooting and reduce the need for manual intervention. This robust connectivity transforms the Venturi flowmeter from a simple measuring device into an intelligent and integral component of a connected, automated process.

A Dependable Solution for Top-Tier Demands

In conclusion, the Venturi flowmeter is a highly accurate and durable solution for flow measurement in the most demanding industrial applications. Its classical design, with its low permanent pressure loss and resistance to wear, ensures long-term stability and a low total cost of ownership. It is an ideal choice for a wide range of critical applications, from power generation and refineries to custody transfer and billing. The complete, single-source solution, which includes all necessary components, engineering, and documentation, simplifies the entire process from selection to installation. With advanced features such as redundancy and modern communication protocols, the Venturi flowmeter is a comprehensive and reliable flow measurement solution. It is a testament to the power of a well-engineered design, delivering consistent and accurate performance in the most challenging environments.

Specifications

Specifications

Depending on selected device configuration

General information

| Product type | Flowmeter |

| Product positioning | For the highest requirements of accuracy and long-term stability |

| Measurement principle | Differential pressure |

| Nominal diameter / size | DN50…1200 / 2…48 |

Operating conditions

| Process pressure | max. 350 bar / 5077 psi |

| Process temperature | -175°C…+720°C / -283°F…+1328°F |

Materials

| Measuring tube | Austenitic stainless steel (1.4404/316L), Carbon steel (A105), Alloy steel (ASTM A182 Gr. F12), Alloy steel (ASTM A182 Gr. F22), Alloy steel (ASTM A182 Gr. F91) |

Process connections

| Flange connections | EN (1092-1): DN50…1200 ASME (B 16.5): 2…48″ others on request |

| Other connections | Butt weld ends |

Approvals/Standards

| Certificates/Approvals Others | NACE, Pressure Equipment Directive (PED), ISO/TR 11583 |

| Certificates/Approvals Ex | ATEX, IECEx, NEPSI |

| Certificates/Approvals Safety | SIL 2/3 |

| Design standards | ASME MFC-3M, ISO 5167-4 |

| NAMUR compliance | NE 107, NE 21, NE 43, NE 53 |

Communication

| Analogue outputs | 4…20 mA |

| Digital outputs | FOUNDATION™ Fieldbus, HART®, Profibus-PA, Bluetooth |

Accuracy

| Reference uncertainty | 0.15 …0.22 % |

Data Sheet

Download Data Sheet Of

Reviews

There are no reviews yet.