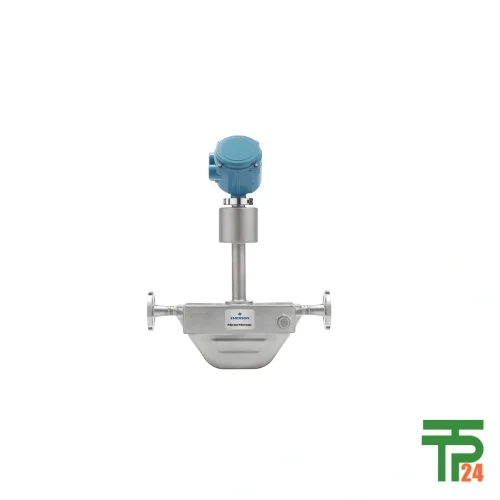

Emerson Micro Motion 3500 Controller And Transmitter

- Mass and Volume Flow Outputs

- HART® and WirelessHART® Communication

- Local Backlit LCD Interface

- 85–265 VAC or 18–30 VDC Powe

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

Micro Motion 3500 Controller And Transmitter

Intelligent Coriolis Control For Industrial Flow Management

The Rosemount 3500 Coriolis Transmitter exemplifies modern engineering convergence between advanced measurement technology and programmable logic control, redefining how industries manage real‑time fluid flow and density analysis. Built on the Series 3000 platform, the 3500 serves as both a Coriolis transmitter and compact PLC, creating a unified instrument capable of mass flow, volume flow, temperature, density, and concentration measurement—all within a single intelligent housing. Designed for custody transfer, net‑oil computation, and marine fuel bunkering, it delivers reliability with high‑speed data processing based on Micro‑Motion MVD (multivariable digital) technology. This foundation translates mechanical vibration into precise flow readings unaffected by pipeline conditions or fluid viscosity changes. The transmitter’s firmware enables batch control, meter verification, and two‑phase flow correction, making it indispensable for refineries, offshore fuel terminals, and energy processing facilities worldwide. Together, these capabilities establish the Rosemount 3500 not only as a measurement device but as a full‑scale automation solution integrating control logic, data acquisition, and instrument self‑diagnostics.

Precision Hardware And Advanced Measurement Architecture

Engineered for uncompromising accuracy, the Rosemount 3500 transforms the traditional Coriolis principle into intelligent multivariable computation. Its dual‑output design features two active 4–20 mA channels, three discrete outputs, and one frequency input plus one frequency output, all coordinated by embedded firmware that synchronizes signal timing to achieve excellent mass‑flow linearity. The transmitter’s digital signal processor (DSP) rectifies nonlinearity and vibration interference, ensuring stable calibration through its full measurement spectrum. A local multi‑line LCD display—128×128 pixels with adjustable contrast and backlighting—provides graphical visualization for mass flow, volume, and density trends, allowing instant verification of the operational state. Large tactile push buttons and software‑defined keys simplify on‑site adjustments without external configuration tools. Combined with the non‑glare acrylic lens, the display meets industrial readability and chemical‑resistance standards. Electrical design flexibility—operating across 85–265 VAC or 18–30 VDC with compliance to IEC 61010‑1—ensures stable power supply integration in both rail‑ and panel‑mounted installations. Every mechanical and electronic element is crafted to maintain accuracy, reliability, and configurability within the intense daily rhythms of fluid‑handling environments.

Multivariable Measurement Enabling Data‑Driven Process Efficiency

The Rosemount 3500 redefines process optimization through simultaneous mass, volume, temperature, and concentration measurement. It uses MVD technology to correlate sensor resonance and fluid dynamics, delivering granular insight into flow behavior under real pressure and temperature conditions. By calculating net product content and flow, operators can track exact material movement across transfer lines—critical for fiscal metering and product custody. The integration of HART® and WirelessHART® communication enables seamless data exchange with distributed control systems (DCS) and plant historians. In production plants, this translates to actionable insights for quality assurance, throughput acceleration, and predictive maintenance scheduling. Continuous density verification prevents process upsets by instantly recognizing entrained gas or phase imbalance. Refinery blending loops, fuel bunkering platforms, and chemical reactors benefit from these multivariable diagnostics, converting basic flow measurement into a dynamic operational intelligence stream. As industries evolve toward digital optimization, the 3500 stands as a benchmark instrument linking fluid analysis to process automation through real‑time precision.

Application Excellence Across Energy And Marine Operations

Specific industrial applications highlight the versatility of the Rosemount 3500 Coriolis Transmitter. In marine fuel bunkering, it ensures precise net‑oil accounting by compensating for temperature, density, and gas entrainment—critical when transferring high‑value fuels in international ports. Refineries deploy it for custody transfer measurement, confirming volumetric equivalence between tanks and loading terminals during fiscal operations. In offshore production units, the instrument’s two‑phase capability allows direct measurement of multiphase streams containing gas slugs or bubbles, eliminating uncertainties in conventional flow meters. Chemical and petrochemical plants use it as a batch controller, automating reagent dosing and formulation based on mass flow feedback. Food and beverage producers apply the 3500 for concentration monitoring—maintaining sugar or additive consistency throughout production lines. Because the unit incorporates PLC logic functionality, users can configure custom alarms, control sequences, and shutoff routines inside the transmitter itself. This adaptability makes the Rosemount 3500 ideal for environments seeking to consolidate measurement, control, and efficiency within a single compact instrument.

User Interface Designed For Control‑Room Integration

Usability defines the Rosemount 3500’s interface philosophy. The large backlit LCD provides instant access to trend data and descriptive alarm notifications, while the intuitive menu structure mirrors common HMI standards for smooth operator transition. Adjustable contrast ensures clarity under various lighting conditions, from refinery panels to engine‑room consoles. The transmitter can be mounted on DIN rail or control‑room panel, providing installation flexibility across plant layouts. Software‑defined keys enable custom shortcuts for function verification, mode switching, or rapid batch initiation. Engineers appreciate the firm tactile feedback of its configurational buttons, designed for operation with protective gloves commonly worn in industrial settings. Furthermore, the transmitter stores configuration sets locally, eliminating dependence on external programming devices. By combining versatile display architecture with ergonomic interaction, the Rosemount 3500 raises the usability standard, facilitating efficient commissioning, smooth real‑time monitoring, and reduced training hours for plant personnel. Each design choice focuses on transparency and simplicity so operators concentrate on production outcomes rather than equipment navigation.

Operational Resilience And Performance‑Driven Reliability

Long‑term reliability is central to the transmitter’s design intent. The Rosemount 3500 drastically minimizes maintenance needs by applying adaptive algorithms that detect sensor drift, thermal shock, and zero offsets automatically. Its embedded Meter Verification suite runs self‑diagnostic routines without process interruption, confirming flow‑tube integrity and transmitter performance. This eliminates mechanical recalibration and secures metrological traceability for extended service intervals. Electrical shielding and reinforced housing protect against electromagnetic interference, enhancing operational stability in plants saturated with heavy machinery. Unlike most compact transmitters limited by single‑variable response, the 3500 sustains multivariable accuracy in dynamically changing fluids with entrained gas. Such resilience translates directly into measurable gains for production: less downtime, improved throughput consistency, and decreased operating expenditure. Engineers relying on 24‑hour continuous flow monitoring—from pipeline distribution hubs to fuel bunkering stations—consider the Rosemount 3500 indispensable for maintaining high precision under all duty cycles.

Reviews

There are no reviews yet.