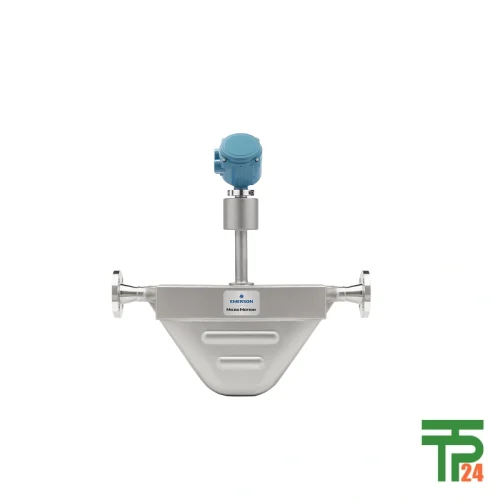

Emerson Micro Motion CDM100M Compact Density Meter

- Accuracy ±0.2 kg/m³ Certified

- Pressure Rating 100 barg Max

- Temperature Up To 204 °C

- 4–20 mA + HART Outpu

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

Micro Motion CDM100M Compact Density Meter

Advanced Compact Density Measurement For Industrial Precision

The Rosemount CDM100M Compact Density Meter represents a breakthrough in liquid density and concentration measurement technology, engineered to deliver custody‑transfer accuracy within the smallest mechanical footprint. Constructed from 316L Stainless Steel with internal Nickel Alloy C‑22 measurement tubes, the CDM100M combines structural durability with a high‑resolution digital sensing core. It quantifies liquid density with ±0.2 kg/m³ accuracy and extraordinary repeatability of ±0.02 kg/m³, establishing performance credibility that rivals laboratory instrumentation in continuous industrial operation. Designed for severe environments, its operating temperature range of –50 °C to +204 °C (–58 °F to +400 °F) and pressure capacity up to 100 barg (1,450 psig) enable deployment across chemical, petrochemical, and process‑control industries. The instrument’s flow velocity indication extends measurement insight with real‑world sample validation for dynamic custody transfer. Combining precision hardware, intelligent firmware, and full hazardous‑area certification, the CDM100M stands at the forefront of global metrology—delivering reliable performance and robust stability wherever density data drives industrial economics and safety compliance.

Engineering Integrity And Multivariable Measurement Architecture

Rosemount CDM100M incorporates computational density modeling firmware that linearizes vibration response across the sensor’s 0–3000 kg/m³ range, covering fluids from light hydrocarbons to heavy process oils and brines. Its polyurethane‑painted aluminum housing secures electronic integrity while resisting corrosion in salty offshore atmospheres. Case RTDs (Resistance Temperature Detectors) inside the sensor continuously adjust for ambient variations, ensuring true compensated results under fluctuating thermal gradients. Each measurement channel converts high‑frequency vibrations into mass‑dependent data, captured and normalized by an embedded microprocessor using pressure and temperature compensation maps derived from calibration under elevated combined test conditions. The transmitter supports HART®, Modbus®, and FOUNDATION™ Fieldbus interfaces, enabling direct integration with DCS, PLC, or flow‑computer infrastructure. Operators achieve traceable performance that complies with ISO/IEC 17025 laboratory standards and MID custody‑transfer directives, backed by optional Known Density Verification (KDV) functions ensuring immediate confidence in sensor accuracy. The result is an exceptionally integrated measurement architecture designed for real‑world reliability and precision under complex industrial dynamics.

Performance Reliability Through Intelligent Calibration And Diagnostics

The precision and consistency of the Rosemount CDM100M come from a dual‑mechanism calibration philosophy—elevated temperature plus pressure compensation—that replicates operational stress conditions during factory testing, minimizing drift throughout the instrument’s lifetime. Embedded diagnostic algorithms monitor sensor health by tracking resonance frequency, internal RTD feedback, and electronics noise, detecting uncertainties before they affect process performance. The optional segmented two‑line LCD display, mounted to the transmitter, provides visual confirmation of diagnostics, configuration, and alerts. A three‑color LED summarizes operational status: green for normal operation, amber for warnings, and red for critical alerts. Technicians benefit from optical switch controls, which allow interaction inside hazardous zones without opening the housing, thereby maintaining explosion‑proof certification. Additionally, the CDM100M’s intelligent internal health verification eliminates external recalibration cycles, reducing long‑term maintenance costs. Industries leveraging the instrument—chemical refineries, petrochemical blending plants, and gas‑extraction facilities—value this diagnostic depth for ensuring continuous measurement continuity, environmental safety, and fiscal accountability.

Dedicated Applications Enhancing Operational Effectiveness Worldwide

The Rosemount CDM100M’s application scope reaches far beyond standard density measurement. In custody transfer systems, where liquid hydrocarbons or refined chemicals are commercially exchanged, the system ensures traceable precision that satisfies metrological agencies across continents. Within concentration measurement platforms—such as ethanol mixing or glycol recovery units—the device quantifies exact solution ratios, supporting process consistency and quality certification. In marine fuel bunkering, the combination of pressure calibration and real‑time flow velocity verification prevents custody disputes and billing inaccuracies. Food and beverage manufacturers rely on it for continuous density‑based product quality monitoring, ensuring sugar or protein concentration remains uniform throughout production. Laboratories and pilot research plants employ the CDM100M for determining fluid blending characteristics under changing operational parameters, guiding process scale‑up decisions. Each of these applications leverage the meter’s compact body for space‑restricted environments and its digital communication for full automation readiness. The 100M transforms density analysis into a key operational metric—from refinery economics to industrial chemistry—delivering insight that shapes production efficiency globally.

User Interface And Control Philosophy For Efficiency

The transmitter architecture prioritizes ergonomic interaction and clarity. The rotatable LCD display can be adjusted in 90‑degree increments for optimal sight angles along pipeline installations or tank manifolds. Operators easily navigate multi‑language menus to view process variables, acknowledge alerts, and configure mA and RS‑485 outputs. Streamlined menu logic parallels modern HMI standards, making control intuitive and reducing onboarding time. The glass lens and sealed optical selectors maintain safety where ambient gas hazards prevent physical switch activation. Configuration can be executed locally in hazardous zones—an enormous advantage in petrochemical platforms that restrict enclosure opening. Through efficient visual feedback and configurable alarm hierarchy, process engineers secure immediate confidence in reading integrity and instrument health. The CDM100M’s interface is not mere visualization; it represents a communication bridge between measurement science and plant operation. Integrating advanced usability within the transmitter ensures that data interpretation, alarm response, and calibration verification happen in real time, enhancing decision speed and operational safety across global facilities.

Structural Durability And Hazardous‑Area Compatibility Features

At the structural level, the Rosemount CDM100M defines robustness through material selection and design resilience. The measurement assembly employs Nickel Alloy C‑22 (UNS 06022)—resistant against chlorides and chemical corrosion—ensuring long‑term stability in aggressive process streams. All process connections and sensor housings use 316L Stainless Steel, balancing strength, cleanliness, and corrosion resistance. To preserve electronics under harsh conditions, the transmitter housing includes polyurethane protective coating that withstands marine humidity and chemical exposure. The meter holds global hazardous approvals: ATEX, CSA, and IECEx, enabling safe use in explosive Class I Div 1 zones. Its pressure limit of 100 barg corresponds to elevated mechanical safety margins even beyond standard pipeline pressures. Combined, these features ensure that operators in offshore platforms, chemical blending skids, and high‑pressure refineries trust their sensor’s structure without worry. Long‑term deployment demonstrates how industrial durability merges with precision, making the CDM100M synonymous with reliability, safety, and enduring measurement integrity under the most demanding environmental conditions worldwide.

Reviews

There are no reviews yet.