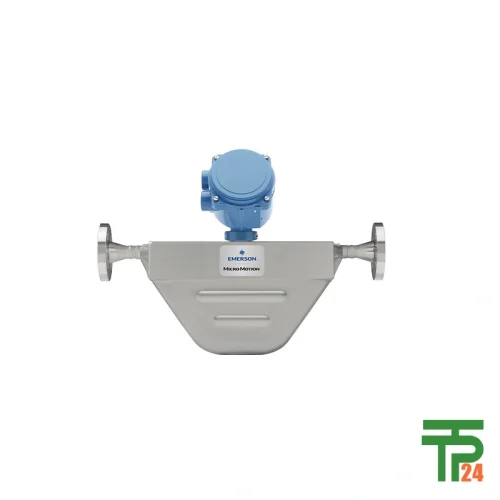

Emerson Micro Motion F025B Coriolis Meter

- Mass Flow Accuracy ±0.10%

- Pressure Rating 149 barg Max

- Temperature Up To 204 °C

- 4–20 mA + HART Output

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

Micro Motion F025B Coriolis Meter

High‑Performance Nickel Alloy Coriolis Flow Measurement

The Rosemount F025B Coriolis Flow Meter stands as a premier metering solution for industries demanding extreme reliability, repeatability, and precision in high‑temperature, high‑pressure environments. Constructed from Nickel Alloy C‑22, this sensor offers unmatched corrosion and chemical attack resistance, making it ideal for aggressive fluid processes such as concentrated acids, chlorinated solvents, and harsh petrochemical blends. With mass‑flow accuracy up to ±0.10% of rate and volume‑flow accuracy ±0.10% in optional calibration, it delivers fiscal‑grade measurement for custody transfer and production control. Gas flows benefit from ±0.5% accuracy with reliable ±0.25% repeatability, ensuring stability even during rapid state changes. Operating up to 149 barg (2,160 psig), the F025B handles challenging service conditions without compromise to data fidelity. Its compact, drainable design simplifies pipeline integration and sanitary maintenance, positioning it as a core operational asset where material durability and precision metrology are critical to process integrity worldwide.

Engineered Strength From Premium Nickel Alloy C‑22

The F025B’s mechanical architecture maximizes process longevity through its use of Nickel Alloy C‑22 (UNS N06022), a material praised for resisting localized corrosion, pitting, and crevice attack in oxidizing and reducing media. This high‑integrity construction ensures safe deployment in chemical reactors, offshore drilling platforms, and chloride‑rich environments while maintaining calibration stability across thermal extremes. The sensor’s geometry is engineered for ideal Coriolis tube resonance, preventing signal deviation under turbulent or pulsating flows. Rated for elevated temperatures up to +204 °C (400 °F), it sustains continuous operation without structural fatigue. Rugged enclosure designs meeting IP66/IP67 ingress protection guarantee immunity from dust and moisture intrusion, even during high‑pressure washdowns. By marrying precision engineering with the chemical resilience of C‑22, the F025B achieves a balance of longevity, stability, and accuracy unmatched among high‑performance Coriolis meters available to industrial metrology today.

Advanced MVD Electronics And Intelligent Diagnostics Capability

Powered by Emerson’s MVD™ (Multivariable Digital) technology, the F025B delivers rapid data updates for responsive batch and continuous measurement, ensuring process control with minimal lag. Integrated electronics manage real‑time mass, volume, density, and temperature calculations, leveraging spectral frequency analytics to detect coating build‑up, tube stress, or thermal distortion. Density measurement achieves ±0.002 g/cm³ (±2.0 kg/m³) standard accuracy and improves to ±0.001 g/cm³ (±1.0 kg/m³) with optional calibration. An on‑board historian and logging system archives flow data for audit and quality assurance purposes, supporting ISO/IEC‑compliant traceability. Smart Meter Verification runs automatic in‑line performance tests, confirming operation health without process interruption. Through advanced electronics, predictive diagnostics, and compliance‑ready calibration, the F025B ensures operators maintain absolute confidence in every reading across complex production and transfer networks.

Specialized Applications Across Global Industrial Operations

The Rosemount F025B is purpose‑built for industries where corrosion resistance, measurement exactness, and operational safety are non‑negotiable. In custody transfer pipelines, its MID OIML R‑117, NTEP, Measurement Canada, and INMETRO Brazil approvals guarantee fiscal reliability. Chemical manufacturing plants deploy the meter for high‑purity acid dosing and caustic blending, leveraging its C‑22 alloy resilience for uninterrupted service. Oil and gas operators use it to measure corrosive crude, condensate, or injection chemicals under high pressure. In pharmaceutical and biotech facilities, it supports precise control of solvent mass flow with full clean‑in‑place drainability. Marine bunkering stations benefit from its fast response times for exact batch measurements during vessel fuel transfer. Even industrial gas networks employ the F025B for rapid natural gas or specialty gas mass calculations with high‑pressure tolerance. This breadth of applications underscores its role as a universal measurement instrument for mission‑critical, corrosion‑prone processes worldwide.

Operator‑Friendly Interface And Flexible Connectivity Options

The F025B transmitter integrates a clear, two‑line LCD display, rotatable for optimum readability in any installation orientation. Real‑time measurement variables—mass flow, volume flow, density, and temperature—are presented with diagnostic icons for immediate health assessment. Configuration is facilitated via standard protocols, including HART®, Modbus®, FOUNDATION™ Fieldbus, and discrete connections, allowing integration with modern DCS or PLC platforms. Menu navigation supports multiple languages for global deployment, and outputs are adjustable directly from the display without external calibration rigs. The compact, drainable sensor body ensures rapid serviceability, reducing downtime during process changeovers. By simplifying user interaction and maintaining compatibility with diverse automation infrastructures, the F025B ensures operational agility for technicians and engineers in any industrial setting.

Comprehensive Safety And Certification Compliance Portfolio

Certified under UL, CSA, IECEx, NEPSI, and ATEX, the F025B meets hazardous‑area installation requirements across global jurisdictional standards. Its CSA zones—Class I Div 1 groups C/D and Class I Div 2 groups A-D—cover diverse operational risks. EMC compliance guarantees measurement immunity to electrical noise or frequency interference from nearby heavy equipment. NAMUR compatibility and IP66/IP67 ratings extend protection against exposure to dust, liquids, or washdown events. The meter withstands 149 barg maximum pressure, reinforced through Emerson’s elevated temperature and pressure calibration regimen. This comprehensive safety and compliance structure permits deployment in offshore rigs, petrochemical terminals, chemical reactors, and marine transfer stations without compromising operator safety or measurement quality—even under hazardous process demands.

Reviews

There are no reviews yet.