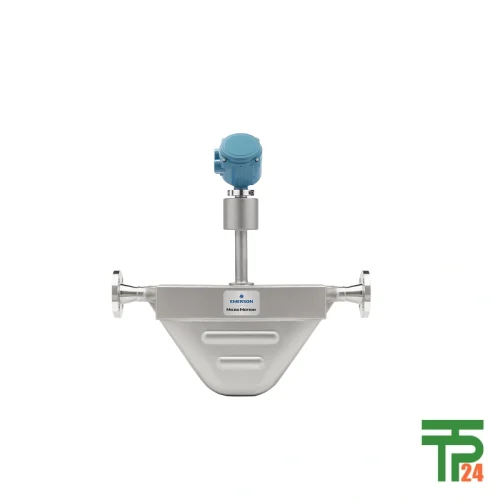

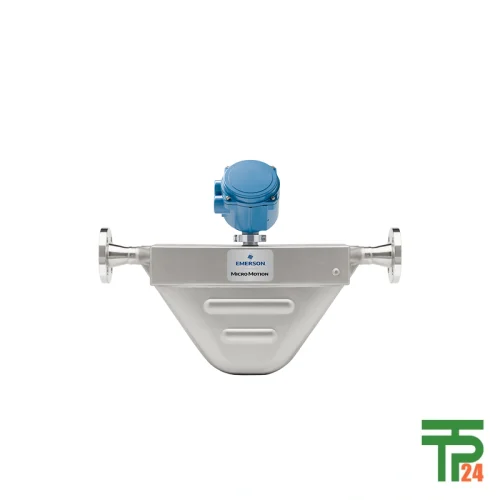

Emerson Micro Motion F025H Coriolis Meter

- Mass Flow Accuracy ±0.10%

- Pressure Rating 149 barg Max

- Temperature Up To 204 °C

- 4–20 mA + HART Output

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

Micro Motion F025H Coriolis Meter

Strategic Accuracy For High‑Pressure Flow Control

The Rosemount F025H Coriolis Flow Meter represents the pinnacle of precision in modern fluid measurement technology. Engineered from Nickel Alloy C‑22, a material renowned for its chemical and corrosion resistance, the F025H ensures data stability even under extreme process conditions. With mass‑flow accuracy up to ±0.10% of rate, volume‑flow precision to ±0.10%, and repeatability within ±0.05%, this instrument defines reliability for both liquid and gas applications across industries worldwide. Its robust construction tolerates pressure up to 149 barg (2,160 psig), making it ideal for gas compression, chemical dosing, petroleum transfer, and reactive fluid blending. Unlike traditional flow meters dependent on inferential models, the F025H directly measures fluid mass with exceptional confidence, offering true process accountability for every cubic meter. Compact yet powerful, its drainable geometry guarantees hygiene and maintenance ease while maintaining traceable calibration integrity in high‑pressure operations.

Durable Construction Using Premium Nickel Alloy C‑22

Performance begins with material excellence. The F025H’s Nickel Alloy C‑22 (UNS N06022) construction offers industry‑leading defense against pitting and crevice corrosion, critical in oxidizing and reducing environments rich in halides or chlorides. Its metallurgical composition grants mechanical strength and oxidation resistance far superior to conventional stainless steels, enabling reliability even in high‑temperature chemical reactors and marine terminals. Each flow tube is precision tuned to maintain Coriolis oscillation balance across the meter’s expected density range, eliminating signal drift under vibration or pressure variation. The outer housing, certified to IP66/IP67 ingress protection, prevents moisture intrusion and particle contamination. Rated for temperatures up to +204 °C (400 °F), the sensor endures demanding processes including acid neutralization, steam heating, and high‑shear polymer production. Its compact and drainable form promotes full pipeline evacuation while supporting clean‑in‑place routines—perfect for pharmaceuticals and food manufacturing. In harsh facilities demanding strength and purity, F025H excels effortlessly.

Next‑Generation MVD™ Electronics And Intelligent Diagnostics

Inside the F025H lives Emerson’s Micro‑Motion MVD™ (Multivariable Digital) transmitter technology—unquestionably among the most advanced signal‑processing architectures in the field. MVD synthesizes motion frequency, amplitude, and phase information from each vibrating tube to produce instantaneous calculations for mass‑flow, density, and temperature. Its digital filtering delivers ultra‑fast response rates required in batch dosing and fiscal custody transfer. The system’s Smart Meter Verification (SMV) conducts non‑intrusive health diagnostics, identifying mechanical integrity, coating buildup, or signal noise without stopping the process. Coupled with a built‑in historian, the transmitter stores trend data for auditing and predictive maintenance. For density measurement, accuracy reaches ±0.002 g/cm³ (±2.0 kg/m³) standard and improves to ±0.001 g/cm³ (±1.0 kg/m³) under optional calibration, maintaining traceability across international metrology standards. By unifying electronic precision with field durability, the F025H’s MVD electronics redefine reliability expected from high‑pressure flow instrumentation today.

Dedicated Applications Across Process Industries Worldwide

The Rosemount F025H operates in mission‑critical applications where data integrity equals productivity. In custody transfer pipelines, fiscal‑grade accuracy ensures contract compliance and transparent billing between energy producers and distributors. Refineries and petrochemical complexes employ the F025H for additive blending, catalyst feed monitoring, and corrosive reagent flow control. Chemical manufacturers rely on its material strength to handle acids such as hydrochloric or sulfuric during neutralization and chlorination stages. In marine fuel bunkering, it provides robust measurement precision in brackish or salt‑laden environments. Pharmaceutical industries use its compact, drainable design to guarantee sterility and exact solvent dosing during formulation. Food and beverage plants utilize the meter for controlled syrup blending or enzyme introduction within hygienic lines. Gas producers adopt the F025H for measuring compressed gases such as hydrogen, carbon dioxide, and nitrogen with high repeatability. Each sector benefits from its resistance, repeatability, and trustworthiness within global metering networks.

User Accessibility And Flexible Integration Empower Control

Ease of operation defines the F025H experience. The transmitter provides a rotatable, back‑lit LCD interface, enabling direct programming and live visualization of flow parameters in real time. Key measurements—mass flow, volume flow, density, and temperature—display simultaneously with diagnostic indicators for sensor health. Menu systems simplify configuration and language adaptation, enhancing global usability. Digital connectivity supports HART®, Modbus®, FOUNDATION™ Fieldbus, and discrete I/O selections for universal compatibility with PLC and DCS architectures. The compact transmitter footprint suits skid installations and limited access panels, while the drainable body permits complete fluid evacuation during shutdown for streamlined maintenance. Operators appreciate that calibration verification can occur electronically via Smart Meter Verification—the device proving its accuracy at the push of a button. Through intuitive digital control and interoperability, the F025H upgrades process efficiency while empowering technicians with transparent data and effortless configuration.

Reviews

There are no reviews yet.