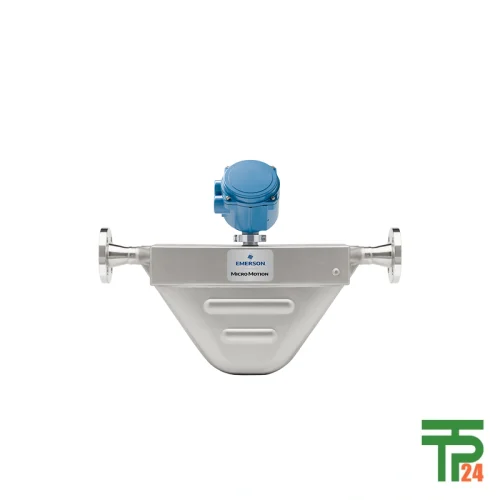

Emerson Micro Motion F025P Coriolis Meter

- Mass Flow Accuracy ± 0.10% Rate

- Pressure Rating 160 barg Max

- Temperature Up To 204 °C

- 4–20 mA + HART Output

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

Micro Motion F025P Coriolis Meter

Precision Measurement For Demanding Industrial Applications

The Rosemount F025P Coriolis Flow Meter stands at the cutting edge of process instrumentation, combining high‑pressure endurance with superior measurement accuracy and stability. Constructed from both 316L Stainless Steel and Nickel Alloy C‑22, this device ensures performance integrity in corrosive, abrasive, and reactive fluid environments. It achieves mass‑flow accuracy up to ± 0.10% (optional) and repeatability within ± 0.05%, delivering the fiscal precision needed for custody transfer operations worldwide. Volume‑flow performance mirrors this excellence, with equally precise tolerance bounds for liquid and gas phases. Operating confidently to 2,320 psig (160 barg), it handles aggressive compression processes and volatile mixtures without drift or signal distortion. Compact, drainable construction fits seamlessly into tight process manifolds or modular skids. F025P’s robust architecture ensures reliable data where critical accountability—fuel batching, catalyst dosing, or fluid blending—defines profitability. In every industrial landscape, this meter represents uncompromising accuracy under maximum mechanical stress.

Dual‑Material Strength For Ultimate Process Assurance

Built from 316L Stainless Steel and optional Nickel Alloy C‑22, the Rosemount F025P achieves unmatched corrosion resistance and mechanical rigidity. Stainless steel supports broad application versatility in general chemical, food, and beverage service, while Alloy C‑22 expands suitability to halide‑rich, oxidizing, and acidic process streams. The flow tubes are precision‑balanced for stable Coriolis vibration response, minimizing resonance distortion and maintaining calibration throughout thermal variation. Internal purge fittings or rupture‑disk options provide safety release during abnormal process spikes, protecting downstream equipment. The body’s IP66/IP67 ingress protection safeguards against dust and liquid penetration under manual washdown or marine humidity. Rated for temperatures to +204 °C (400 °F), this dual‑material design excels in heated chemical reactors, steam injection systems, and hygienic processing applications. Ruggedness meets adaptability, allowing the F025P to operate across extreme conditions—from sterile pharmaceutical batching lines to offshore chemical dosing—without compromise in instrument integrity or repeatable performance.

Advanced MVD™ Digital Electronics And Diagnostics Technology

At the heart of F025P lies Emerson’s MVD™ (Multivariable Digital) signal processor engine, designed to interpret Coriolis vibrations with exceptional precision and speed. Rapid extraction of phase, frequency, and amplitude delivers instantaneous real‑time calculation of mass flow, density, and temperature. Smart Meter Verification (SMV) enables continuous performance validation without halting production—an invaluable feature for facilities demanding regulatory compliance and continuous audit readiness. Built‑in historian and logging systems record dynamic process parameters, giving operators full data visibility for trend analysis and predictive maintenance. Density measurement boasts ±0.002 g/cm³ standard accuracy and can be refined to ±0.001 g/cm³ optional calibration, securing absolute precision even under variable viscosity or compressibility conditions. Enhanced electronics provide temperature accuracy ±1 °C ± 0.5% of reading, supporting thermal compensation for fluids with high process sensitivity. These innovations transform the F025P from a conventional flow meter into a digitally intelligent metering solution aligned with the highest international reliability standards.

Versatile Applications Across Global Industrial Operations

The Rosemount F025P serves diverse, demanding applications where process safety and measurement accuracy are paramount. In custody transfer pipelines, its certified fiscal accuracy guarantees transparent transaction reporting between energy producers and downstream distributors. Petrochemical facilities utilize this meter for additive manipulation, polymer feed control, and solvent dosing, handling pressurized fluids with confidence at 160 barg. Chemical manufacturers employ it for acid handling, caustic blending, and oxidizing agent feed where conventional sensors suffer premature failure. Pharmaceutical operations integrate F025P for precise solvent measurement in sterilized reactors, leveraging its drainable geometry for clean‑in‑place validation. Food and beverage processors depend on its sanitary flow path for dosage control during syrup or enzyme blending. Marine bunkering systems use it for high‑pressure fuel transactions in harsh saline environments. Natural gas and hydrogen distribution networks appreciate its repeatability during pressurized flow measurement. Wherever durability and precision define operational success, the F025P delivers unmatched assurance.

Seamless Interface And Universal System Connectivity

Operator accessibility meets technological flexibility in the F025P’s intuitive LCD transmitter interface. The two‑line, back‑lit display rotates for optimized viewing orientation during installation. Real‑time parameters—mass flow, volume flow, density, and temperature—present simultaneously with diagnostic indicators highlighting sensor health. Configuration can be performed locally or via remote protocols including HART®, Modbus®, FOUNDATION™ Fieldbus, and discrete I/O for direct PLC and DCS integration. The compact transmitter footprint simplifies mounting in skids and confined control cabinets. For maintenance, Smart Meter Verification verifies instrument functionality electronically without process disruption, eliminating traditional wet‑calibration cycles. Service engineers appreciate fast firmware accessibility and multilingual display menus supporting global users. Together, these capabilities contribute to total control simplicity, ensuring process transparency and minimizing downtime. The result: a user‑centric Coriolis meter designed equally for reliability, configurability, and operational comfort across multinational industrial facilities.

Reviews

There are no reviews yet.