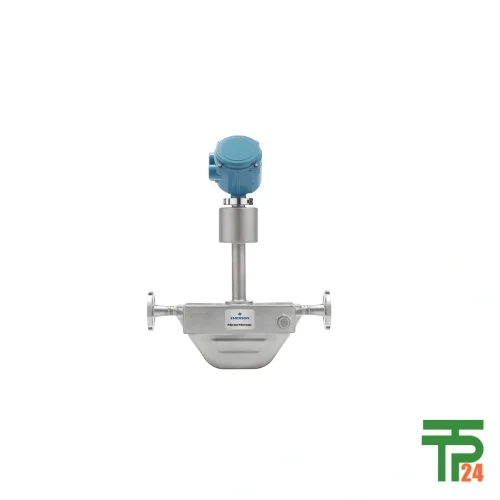

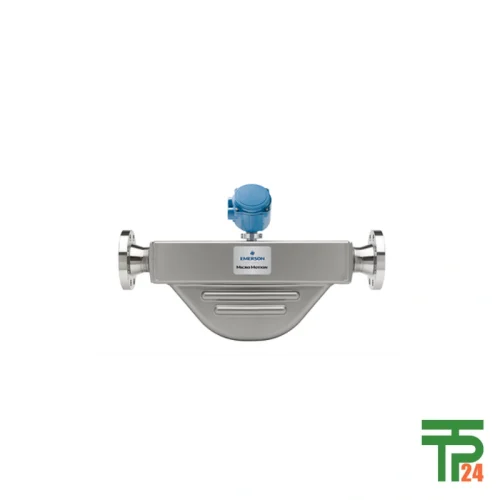

Emerson Micro Motion F050S Coriolis Meter

- Mass Flow Accuracy ± 0.10% Rate

- Pressure Rating 100 barg Max

- Temperature Up To 204 °C

- 4–20 mA + HART Output

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

Micro Motion F050S Coriolis Meter

Compact Stainless Precision For Complex Industrial Measurement

The Rosemount F050S Coriolis Flow Meter embodies Emerson’s commitment to compact engineering excellence, precision, and long‑term process reliability. Built entirely from 316L Stainless Steel, it ensures full corrosion resistance, hygienic compatibility, and mechanical stability under demanding process loads. Operating at pressures up to 1,450 psig (100 barg) and temperatures reaching 204 °C (400 °F), the F050S provides consistent and accurate measurement for liquids, gases, and mixed‑phase formulations. Users achieve mass flow accuracy ± 0.10% of rate and repeatability as tight as ± 0.05%, positioning it among the most trustworthy instruments in the F‑Series line. Its drainable design minimizes trapped residue after each batch, ensuring purity and preventing contamination—a critical requirement for food, pharmaceutical, and fine‑chemical sectors. Combined with Emerson’s proprietary digital electronics, the F050S delivers robust, repeatable results under variable viscosity and thermal conditions. In industries where precision defines profitability, this meter offers recurring metrological stability with durability proven across every process domain.

316L Stainless Construction Delivering Long-Term Durability Assurance

The mechanical strength and corrosion resistance of 316L Stainless Steel form the backbone of the F050S’s unmatched reliability. This low‑carbon alloy offers superior resistance to chloride attack and acidic corrosion, making it suitable for both aggressive chemical and hygienic process applications. Its smooth internal surface eliminates flow obstruction and buildup, promoting laminar movement and accurate reading stability. The unit’s design integrates a fully drainable geometry for rapid cleaning, critical in sanitary environments such as bio‑pharma or beverage manufacturing. Additionally, the meter withstands repeated steam sterilization cycles without deformation or calibration drift. For marine and offshore installations, 316L extends longevity under saline conditions, while in energy plants it endures thermal and pressure fluctuations with unyielding precision. The F050S thus stands as the material benchmark in Emerson’s industrial portfolio—combining compact form factor, corrosion‑proof metallurgy, and dimensional consistency essential for years of unbroken metering performance.

Digital MVD™ Signal Processing And Smart Diagnostics Reliability

Emerson’s MVD™ (Multivariable Digital) technology empowers the F050S to interpret intricate sensor oscillations more rapidly and accurately than conventional analog systems. Each flow tube resonance is digitally analyzed, removing noise interferences from vibration or temperature drift. The result is unmatched stability across broad measurement ranges for both liquid and gas flows. Complementing this, Smart Meter Verification (SMV) offers continuous self‑diagnostic analysis—detecting early signs of mechanical or electronic deviation before errors propagate. The onboard historian and logger archive process data for verification, enabling maintenance teams to substantiate instrumentation integrity instantly. Temperature readings remain accurate within ± 1 °C ± 0.5% of reading, while density measurements reach ± 0.0005 g/cm³ (optional), delivering laboratory‑grade precision directly in the plant environment. This digital pairing guarantees that the F050S not only measures but monitors itself—a combination of intelligence and reliability that fundamentally transforms traditional process assurance into autonomous, verifiable confidence.

Specific Industry Applications Across Global Process Markets

The F050S finds application in a wide range of industries requiring precise flow and density measurement within compact systems. In chemical processing, it operates flawlessly in acid neutralization, polymer dosing, and solvent recovery lines. Pharmaceutical plants depend on it for sterile ingredient flow control and batch consistency during formulation. Food and beverage facilities utilize its hygienic surfaces for measuring syrups, milk, flavor compounds, and fermentation additives under strict sanitary conditions. Petrochemical refineries adopt F050S units within blending manifolds and custody transfer operations for high‑value fuels and lubricants. The marine sector installs it for accurate fuel metering and supply tracking within pressure‑balanced systems. Gas distribution networks use the F050S for monitoring hydrogen or nitrogen streams where precise density correction determines billing integrity. Across these markets, the meter’s resilience, cleanliness, and compactness define its universal adaptability. It serves not only as a transactional instrument but also as an operational cornerstone within advanced fluid‑control architecture worldwide.

Operational Ease And Seamless Digital Network integration

Engineers appreciate the simplicity of operating the F050S through its rotatable, back‑lit LCD display, which exposes live data on mass, volume, and density at a glance even under glare or low‑light environments. The instrument communicates effortlessly with control systems via HART®, Modbus®, and FOUNDATION™ Fieldbus networking protocols, supporting easy parameter adjustment and calibration. Installation is quick due to compact transmitter housing and intuitive electrical connectivity. Every function—from Smart Meter Verification to flow trending—can be executed remotely, minimizing manual interference and downtime. Integrated technology enables real‑time validation of measurement data, reinforcing accuracy and verifying mechanical health continuously. For high‑pressure processes managed within PLC or SCADA systems, this meter provides instant transparency of performance variables. Operators can schedule calibration or predict maintenance intervals based on historical analytics—transforming traditional metering into intelligent asset management. Ease of use, combined with digital flexibility, makes the F050S a fully network‑ready meter for connected industrial infrastructures.

Comprehensive Global Approvals And Legal Measurement Compliance

A key strength of the F050S is its extensive list of international certifications validating its safe operation under multiple industrial conditions. These include UL, CSA, IECEx, NEPSI, and ATEX approvals, classifying it for installation in both explosive and non‑hazardous areas. The meter fulfills Class I Div 1 groups C and D and Class I Div 2 groups A–D installation safety standards. In addition, it meets Ingress Protection IP66/IP67, protecting electronic components from dust intrusion and water exposure, crucial in marine or chemical environments. Compliance with NAMUR EMC ensures immunity against electromagnetic interference, retaining output clarity near high‑power equipment. Fiscal precision is backed by Custody Transfer Approvals, including MID OIML R 117, NTEP, Measurement Canada, and INMETRO Brazil, enabling commercial transaction validity worldwide. These collective endorsements guarantee long‑term reliability and ensure Emerson’s meters remain legally recognized tools for precision measurement and international trade.

Reviews

There are no reviews yet.