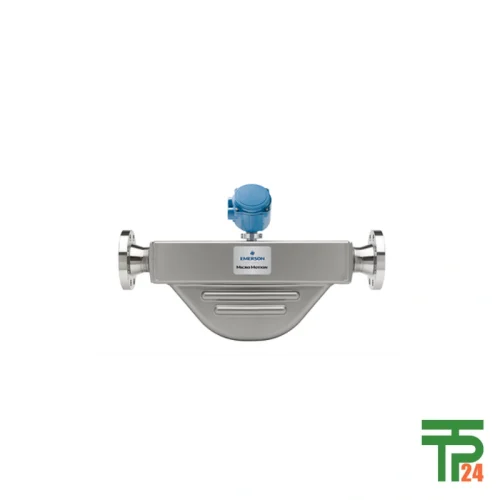

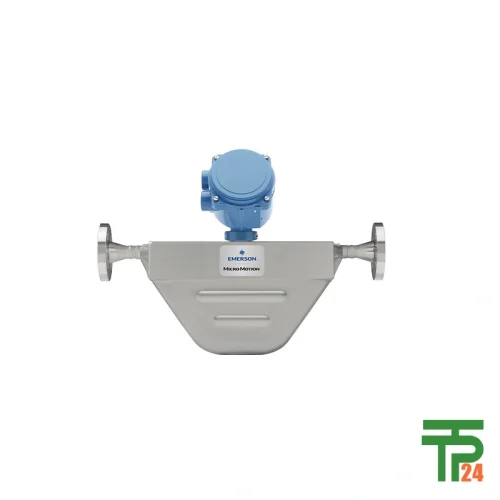

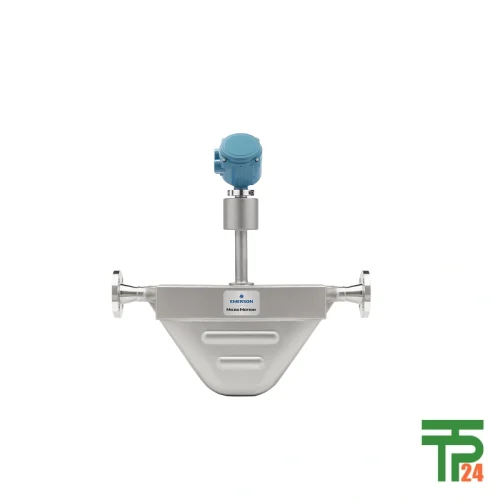

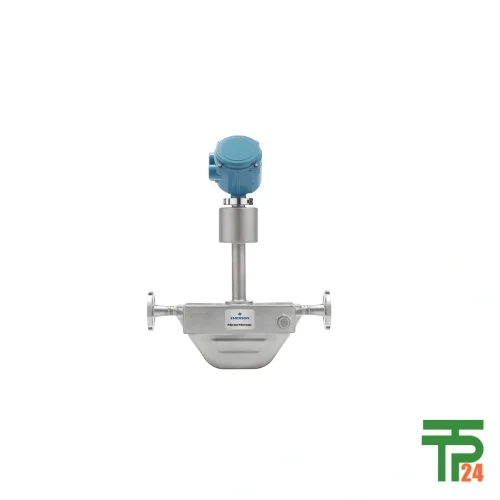

Emerson Micro Motion F100A Coriolis Meter

- Mass Flow Accuracy ± 0.10% Rate

- Pressure Rating 100 barg Max

- Temperature Up To 204 °C

- 4–20 mA + HART Output

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

Micro Motion F100A Coriolis Meter

High Temperature Accuracy For Complex Fluid Measurement

The Rosemount F100A Coriolis Flow Meter epitomizes Emerson’s advanced instrumentation design, merging high‑temperature durability with world‑class measurement precision. Constructed from 316L Stainless Steel, this meter delivers persistent, repeatable performance across complex fluid compositions and severe operating environments. It withstands pressures up to 1,450 psig (100 barg) and supports process temperatures reaching +204 °C (400 °F), ensuring stable measurement even in thermal cycling conditions. The F100A achieves liquid mass flow accuracy as tight as ± 0.10% of rate (optional) and repeatability ± 0.05%, surpassing industry norms for process control and custody transfer. The compact, drainable geometry guarantees fluid purity after every batch, minimizing contamination risks. Combining the renowned Emerson mechanical stability with optimized tube geometry, the F100A provides an ideal balance between precision and robustness. This meter stands ready for high‑temperature measurement applications that demand proven long‑term reliability—from petrochemical synthesis to food sterilization cycles—where every fraction of measurement deviation carries financial relevance.

316L Stainless Steel Ensuring Extended Lifecycle Reliability

Durability defines the engineering core of the F100A. Its full 316L Stainless Steel construction grants exceptional corrosion resistance and structural stability for both neutral and aggressive chemical environments. The alloy’s low carbon content prevents intergranular corrosion even under continuous exposure to heat or pressurized oxidizing conditions. Each measuring tube is precision‑machined and polished internally to eliminate deposits, maintaining flow uniformity and accuracy across viscous, complex, or particle‑laden fluids. Emerson’s finite element testing confirms the mechanical resilience of every sensor assembly under repetitive thermal stress and vibration. For sectors handling acids, solvents, and sanitary compounds, the F100A guarantees zero contamination thanks to its completely drainable design and inert surface finish. Its resilience equally benefits offshore fuel blending, oil production, and chemical neutralization loops, where aggressive compounds and high temperature challenge equipment lifespan. This stainless‑steel foundation ensures not only stability but continuity—making the F100A inherently dependable for continuous‑operation environments worldwide.

MVD™ Technology And Smart Meter Verification Assurance

Within the F100A lies Emerson’s MVD™ (Multivariable Digital) transmitter platform—a technology enabling instantaneous interpretation of sensor signals, insulating the data from drift, noise, or mechanical distortion. MVD™ calculates mass flow, volumetric flow, density, and temperature simultaneously, ensuring high‑speed accuracy and reducing error propagation in dynamic process conditions. Complementing it is Smart Meter Verification (SMV), Emerson’s diagnostic innovation assessing the live health of mechanical and electronic modules. SMV performs non‑intrusive verification tests to confirm the ongoing reliability of measurement without halting process flow, preserving uptime while guaranteeing calibration certainty. The integrated on‑board historian and logger archive operational trends and alarm events for streamlined maintenance analysis and compliance documentation. Temperature accuracy reaches ± 1 °C ± 0.5% of reading, while optional density precision attains ± 0.001 g/cm³, meeting laboratory standards on‑site. MVD™ and SMV thus form the digital shield securing integrity, accountability, and accuracy of flow data across all industrial domains employing the F100A.

Dedicated Industrial Applications Across Global Production Fields

The F100A serves as an indispensable tool within industries demanding extreme‑temperature metering integrity. In petrochemical and refining plants, it measures heated hydrocarbons, catalyst feeds, or vapor‑phase fractions for fiscal reporting and blend optimization. Chemical processing systems employ the F100A for accurate acid handling, high‑temperature polymer dosing, and solvent recycling streams where precision determines reaction yield. Food and beverage facilities rely on its sanitary, drainable design to track syrup, oil, and flavor compound flow during pasteurization or sterilization cycles, ensuring purity and consistency. Pharmaceutical manufacturers leverage it in controlled reactor loops and hot‑solvent feed lines critical to formulation repeatability. Power generation applications include turbine fuel measurement, condensate recovery, and superheated liquid circulation monitoring for heat‑balance optimization. Even marine and offshore industries integrate the F100A for hot‑fuel custody transfer and lubricant monitoring. Across all these sectors, the F100A provides the precision backbone to control, document, and perfect high‑temperature fluid behavior worldwide.

User Interaction And Network Connectivity Excellence

Operational flexibility remains central to the F100A experience. The instrument features a rotatable back‑lit LCD display for clear data visibility under varying light conditions, presenting mass, volume, density, and diagnostic status in real time. It integrates seamlessly into digital plant architectures via HART®, Modbus®, and FOUNDATION™ Fieldbus protocols, permitting remote configuration, calibration, and verification through distributed control systems. Emerson’s software tools allow predictive maintenance scheduling derived from diagnostic logging and historical trend analysis. The meter’s compact form reduces installation footprint, making it ideal for skid assemblies, confined process frames, and modular production setups. Users benefit from intuitive menus and configuration shortcuts enabling quick commissioning even amid ongoing operations. Data‑rich connectivity ensures synchronized performance across entire enterprise networks, transforming traditional metering devices into intelligent process nodes capable of supporting Industry 4.0 automation. Combined digital simplicity and mechanical excellence make the F100A both approachable and future‑ready for every industry it serves.

Specifications

Data Sheet

Download Data Sheet Of

Reviews

There are no reviews yet.