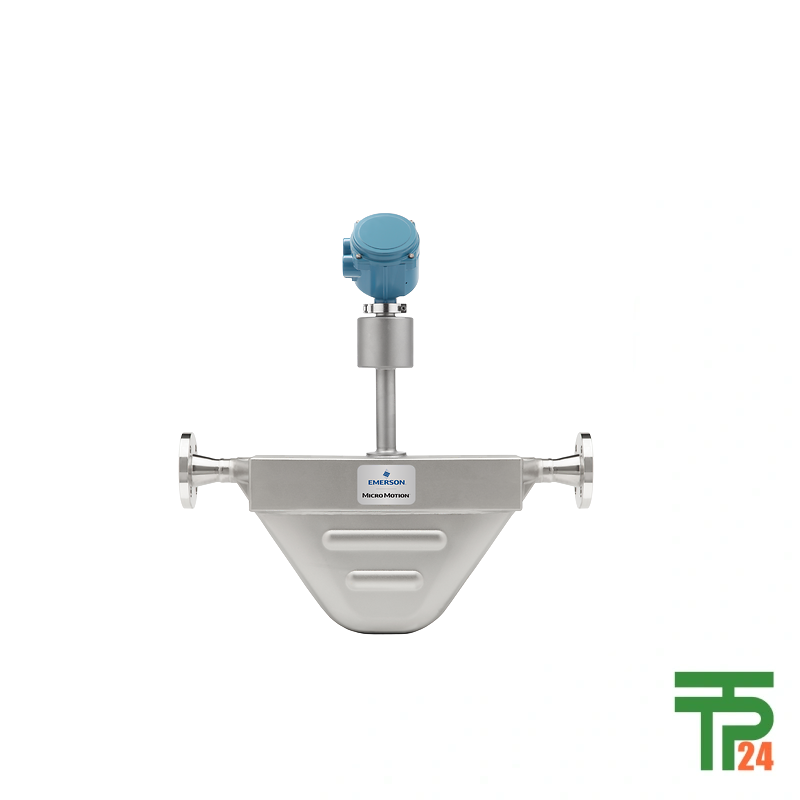

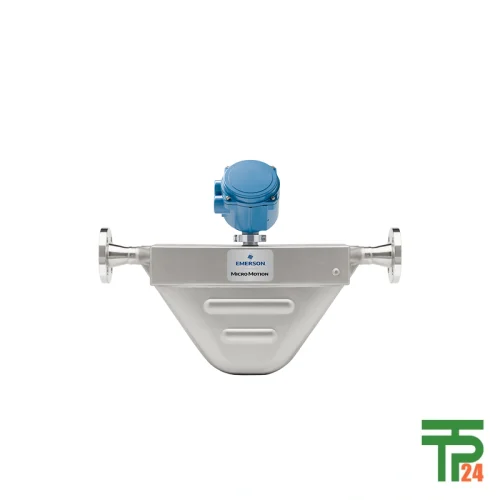

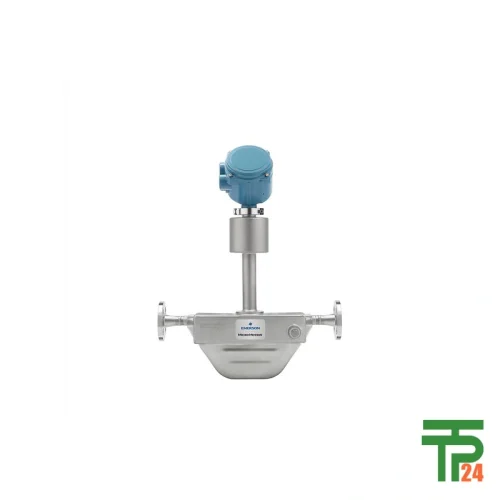

Emerson Micro Motion F100B Coriolis Meter

- Mass Flow Accuracy ± 0.10% Rate

- Pressure Rating 149 barg Max

- Temperature Up To 204 °C

- 4–20 mA + HART Output

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

Micro Motion F100B Coriolis Meter

High Temperature Precision In Nickel Alloy Design

The Rosemount F100B Coriolis Flow Meter embodies Emerson’s advanced measurement engineering, combining high‐temperature capability, multivariable precision, and industrial resilience within a compact instrument. Manufactured using Nickel Alloy C22, this meter delivers outstanding corrosion resistance, particularly against chlorides, acids, and oxidizing fluids common in aggressive process environments. It sustains working pressures up to 2,160 psig (149 barg) while remaining calibrated for process temperatures exceeding +204 °C (400 °F). The F100B guarantees exceptional mass and volume flow accuracy — achieving ± 0.10% of rate (optional) for liquids and ± 0.5% for gases. Repeatability holds at ± 0.05% of rate, allowing operators to maintain process consistency and product purity under thermal and vibrational strain. Its compact, fully drainable configuration promotes cleanliness and efficient maintenance cycles, making it ideal for high‐temperature chemical, refining, and energy systems where stable precision defines operational efficiency. Every facet of its design contributes to durability, dependability, and confidence that measurement integrity remains untouched, regardless of the surrounding process severity.

Nickel Alloy C22 For Extreme Corrosive Applications

The F100B’s construction from Nickel Alloy C22 marks a deliberate advancement over conventional stainless steel designs. This high‐performance material offers superior resistance to oxidizing and reducing agents, including hydrochloric, sulfuric, and nitric acids. The density and microstructure of C22 prevent pitting, crevice corrosion, and metal embrittlement across extreme temperature and pressure conditions. It also ensures consistent mechanical strength and electromagnetic stability around highly conductive fluids. These traits make the F100B ideal for acid chlorination circuits, caustic handling plants, and pharmaceutical reactor loops operating under aggressive chemical exposure. Each sensor element is precision‐polished to preserve flow uniformity, minimizing measurement distortion triggered by turbulence or sediment deposition. The alloy’s ability to withstand 149 barg pressure renders it indispensable for pressurized gas measurement or high‐density fluid control. By integrating Emerson’s corrosion‐proof metallurgy, the F100B becomes a standard for efficiency and endurance, serving industries that require both chemical resilience and consistent, long‐term metrological stability.

MVD™ Transmitter And Smart Meter Verification Reliability

Underpinning every F100B is Emerson’s MVD™ (Multivariable Digital) transmitter technology, a proprietary digital system engineered for rapid and uncompromised data fidelity. This electronic platform simultaneously processes frequency, amplitude, and temperature signals to compute mass, volume, and density with near‐instantaneous precision. The result is faster reaction times during batching or process control while maintaining unparalleled repeatability. Alongside MVD™, Emerson’s Smart Meter Verification (SMV) introduces automated in‐process diagnostics that validate the sensor’s mechanical and electronic health without interrupting flow. Operators can execute SMV tests remotely, confirming calibration integrity against internal reference patterns. Process troubleshooting becomes proactive—detecting fouling, vibration interference, or electronic drift at inception, rather than after error accumulation. Combined with an on‑board historian and data logger, users gain a transparent record of operational stability and historical calibration compliance. MVD™ and SMV thus convert the F100B into a self‑governing instrument that not only measures but safeguards its own accuracy, enhancing both reliability and regulatory traceability across every industrial application.

Focused Application Range Across Diverse Global Industries

The versatility of the Rosemount F100B extends to a wide spectrum of industries functioning under demanding chemical and thermal conditions. In petrochemical production, it governs heated hydrocarbon streams, compressor recirculation lines, and custody transfer stations, where fiscal precision is mandatory for revenue accountability. Refineries employ the meter for high‐temperature catalyst dosing and polymer blending, maintaining optimum composition uniformity. Within chemical plants, its corrosion‑resistant C22 tubing secures measurement reliability in chlorinated or acidified media. Pharmaceutical facilities deploy F100B units for solvent recovery, reagent metering, and sterilized ingredient batching, benefiting from the device’s drainable hygienic design. In food processing environments, the F100B tolerates cleaning‐in‐place cycles and continuous heat sterilization, offering repeatable volume tracking of oils, syrups, and thermally sensitive liquids. Marine and offshore operations rely on its pressure endurance to monitor fuel and glycol transfer under surge conditions. Across these domains, the meter’s mechanical strength and analytic accuracy make it indispensable wherever corrosive chemistry meets elevated temperature and process precision.

Connectivity, Diagnostics, And Operator Accessibility Advantage

Operational convenience defines user interaction with the F100B. Its interface includes a rotatable back‑lit LCD display, readable under glare or dim environments, presenting flow rate, density, and diagnostic status in real time. The unit integrates seamlessly through HART®, Modbus®, and FOUNDATION™ Fieldbus communication protocols, supporting digital control and configuration across distributed automated networks. Emerson’s meter diagnostics system performs continuous self‑monitoring, transmitting alerts directly to supervisory PLC or SCADA systems. Maintenance teams benefit from predictive insights derived from recorded vibration data, temperature drift statistics, and electronic response patterns—all accessible through intuitive dashboards. Compact electronics and robust enclosure guarantee fast installation even in confined frameworks. Combined connectivity allows multi‑sensor field integration, promoting synchronized measurement for batch consistency and process optimization. This connected control flexibility defines modern process management — where operators can configure, verify, and audit their flow metering instruments remotely, maximizing production uptime while minimizing manual intervention in hazardous or inaccessible zones.

Reviews

There are no reviews yet.