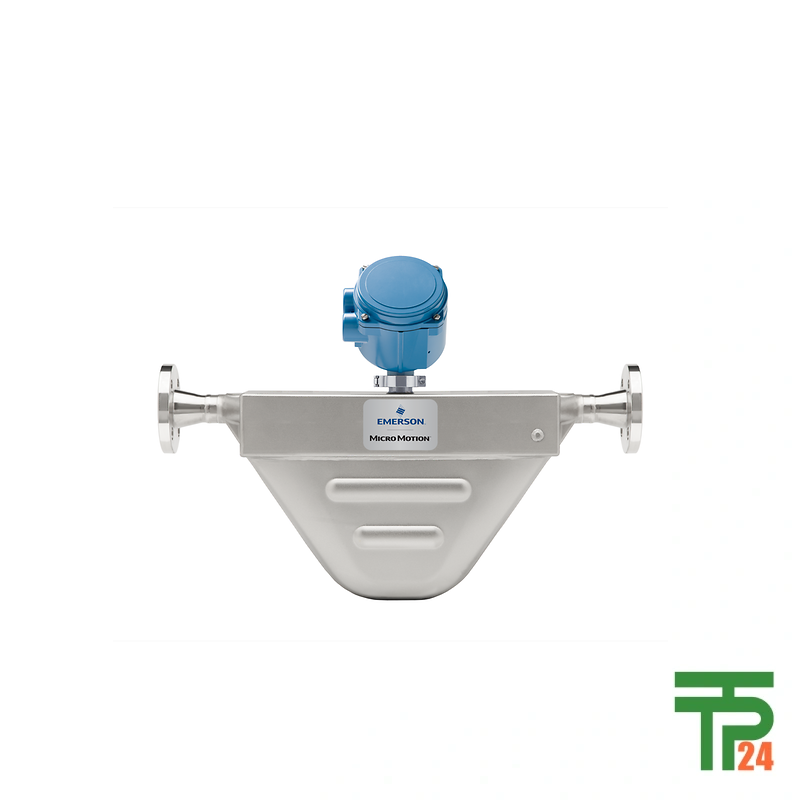

Emerson Micro Motion F100P Coriolis Meter

- Pressure Rating 431 barg Max

- Mass Flow Accuracy ± 0.10%

- Density Accuracy ± 0.002 g/cm³

- 4–20 mA + HART Output

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

Micro Motion F100P Coriolis Meter

High Pressure Precision Through Nickel Alloy Engineering

The Rosemount F100P Coriolis Flow Meter represents Emerson’s culmination of scientific design and process accuracy, combining extreme pressure durability with unmatched reliability in complex industrial conditions. Engineered from Nickel Alloy C22, the F100P stands resilient against aggressive corrosive fluids, heat fluctuations, and mechanical vibration while maintaining exceptional measurement integrity. It tolerates a maximum operating pressure of 6,250 psig (431 barg), far surpassing typical metering limitations. The instrument achieves mass flow accuracy ± 0.10% of rate (optional) and repeatability ± 0.05%, enabling stable, repeatable readings even at micro‑flow levels. Its intrinsic tube geometry and compact drainable housing optimize hydraulic efficiency while minimizing flow disturbances. The F100P’s enhanced rigidity ensures robustness under ultra‑high pressure cycles, making it indispensable in critical service lines such as pressurized gas delivery, hydrocarbon custody transfer, and high‑energy chemical reactions. Emerson integrates advanced flow tube harmonics to neutralize torsional vibration effects, providing a measurement system that endures physically and performs analytically under pressures few instruments could withstand.

Nickel Alloy C22 Ensuring Superior Corrosion Protection

The choice of Nickel Alloy C22 is central to the F100P’s longevity and reliability. Known for exceptional resistance against both oxidizing and reducing chemical media, C22 protects the internal flow tubes from chloride attack, acid exposure, and oxidizing contaminants common to refinery and offshore environments. This alloy maintains structural strength across extreme temperature shifts and provides a non‑reactive surface profile ensuring no contamination of measured fluids. The material’s metallurgical consistency prevents pitting, crevice corrosion, and phase instability—problems that typically plague stainless configurations under prolonged exposure to concentrated acids or brine. By utilizing this sophisticated alloy, Emerson guarantees extended lifecycle performance even within chlorine processing plants, acid recovery units, and marine fuel systems. Furthermore, its low magnetic permeability maintains signal clarity and linear tube motion under electromagnetic influence, preserving purity of measurement for high‑pressure, high‑temperature liquid and gas flow systems. With the F100P, corrosion resistance translates directly into measurement dependability, operational safety, and economic sustainability.

MVD™ Technology Delivering Intelligent Flow Accuracy Control

At the heart of the F100P lies Emerson’s Multivariable Digital (MVD™) transmitter platform—a high‑speed analytical processor that transforms mechanical sensor vibrations into accurate digital readings for mass, volume, and density. MVD™ eliminates drift and signal noise, securing steady data capture across variable process conditions, including rapid pressure shifts or temperature gradients. It performs simultaneous multi‑parameter calculation in milliseconds, allowing smooth control for batching and blending operations. Complementary to MVD™, Emerson integrates Smart Meter Verification (SMV) technology—a diagnostic function verifying sensor structural integrity and electronic responsiveness without process interruption. SMV automatically traces mechanical profiles and compares them with factory calibration baselines, revealing early signs of wear or contamination. Operators benefit from complete in‑process assurance and reduced manual calibration needs. Together, MVD™ and SMV redefine flow verification, offering in‑line proof of measurement honesty and instrument health. These features elevate the F100P from a conventional flow meter to an intelligent diagnostic gateway essential to automated, pressure‑critical process networks worldwide.

Dedicated Industrial Applications In High‑Pressure Domains

The Rosemount F100P thrives in specialized industrial environments where pressure and corrosion challenge ordinary instruments. In petrochemical and refining operations, it manages hydrogen, compressed hydrocarbon streams, and pressurized catalysts vital for reaction control and energy balance monitoring. Chemical manufacturing facilities employ the F100P in acid dilution loops, oxidizer charge systems, and solvent polymerization circuits needing precision under oxidative and corrosive stress. Natural gas processing plants utilize it for fiscal custody transfers, both in upstream and midstream pipelines where gas composition and mass fluctuation demand verified documentation. Pharmaceutical reactor sections exploit its compact drainable design for pressure‑sterilized solvent flow experiments requiring micron‑level density accuracy. Marine and offshore platforms depend on its 431 barg pressure resilience for pump control and bunker fuel measurement amidst vibration and saline environments. Even power generation systems integrate the F100P for steam density monitoring and high‑pressure coolant circulation. Every sector leveraging high‑energy fluid dynamics finds its precision cornerstone in F100P’s robust engineering, ensuring process accountability and integrity globally.

Reviews

There are no reviews yet.