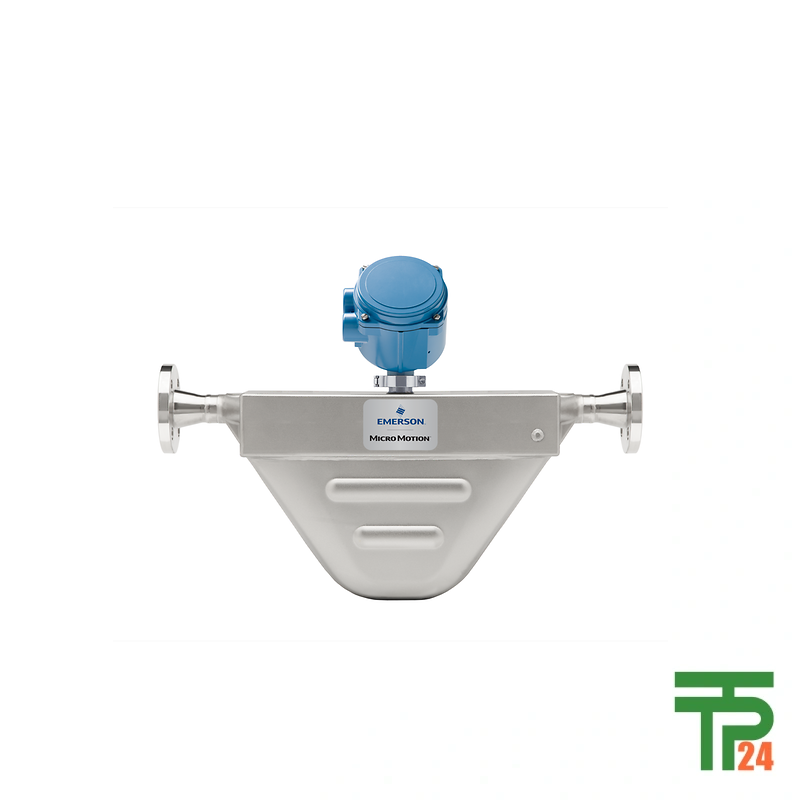

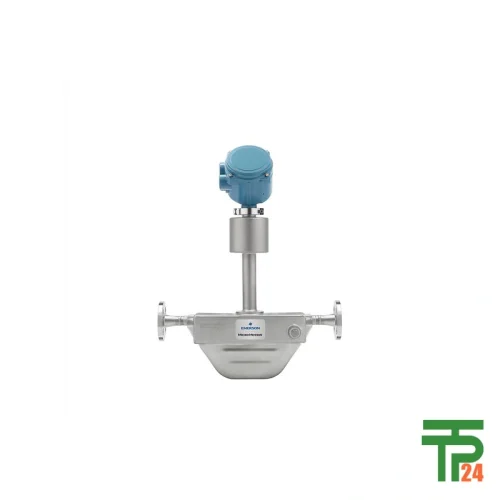

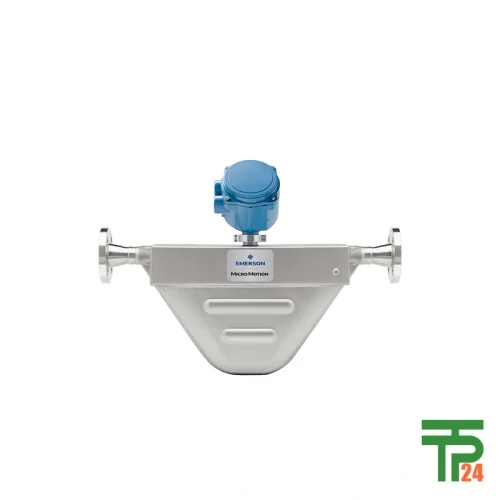

Emerson Micro Motion F100S Coriolis Meter

- Pressure Rating 100 barg Max

- Mass Flow Accuracy ± 0.10%

- Density Accuracy ± 0.001 g/cm³

- 4–20 mA + HART Output

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

Micro Motion F100S Coriolis Meter

Precision Flow Monitoring Through Stainless Steel Integrity

The Rosemount F100S Coriolis Flow Meter exemplifies Emerson’s dedication to unrivaled precision in mass, volume, and density measurement for liquid and gas applications. Constructed from durable 316L Stainless Steel, the F100S ensures both chemical inertness and structural longevity against mechanical fatigue and corrosion. Equipped with compact, drainable tube geometry, it delivers smoothly processed flow data for high‑purity and hygienic duties. Operating with maximum working pressure up to 1,450 psig (100 barg), it supports rigorous process streams while maintaining minimal pressure drop. Emerson’s advanced design promotes remarkable mass flow accuracy rated ± 0.10% of rate (optional) and repeatability ± 0.05%, guaranteeing stable readings during batch transfer and continuous pipeline measurement. Whether employed in petrochemical reactors or sterile pharmaceutical dosing lines, the F100S provides precise, repeatable results under fluctuating process conditions. Its corrosion‑resistant 316L alloy prevents contamination and degradation, ensuring purity for critical analytical fluids. Serving as the benchmark for compact reliability, the F100S integrates durable architecture and unmatched operational integrity in dynamic industrial environments demanding unyielding measurement stability.

316L Stainless Steel Ensuring Measurement Purity And Strength

The F100S achieves reliability through its full 316L Stainless Steel construction, balancing mechanical strength and chemical cleanliness in harsh and sanitary applications alike. Stainless steel’s chromium‑rich microstructure forms a passive oxide film that prevents corrosion, pitting, and scaling even under high chloride exposure. This ensures dimensional stability of the flow tubes, maintaining calibration integrity over extended operational years. In food and beverage processing, its hygienic drainable design and inert surface allow safe flow of syrups, oils, and alcohols without bacterial retention. In pharmaceutical manufacturing, it measures sterile solvents and active ingredients under clean‑in‑place (CIP) procedures. For water treatment and chemical distribution, the alloy withstands oxidizing agents and acids without contamination risks. Emerson’s precision welding and polishing methods result in mirror‑smooth internal finish improving laminar flow transition and lowering turbulence losses. The 316L material thus functions not merely as structural support but as a critical contributor to metrological purity, enabling reliable flow, temperature, and density evaluation in regulated hygienic and corrosive industrial processes worldwide.

MVD™ Signal Processing For Superior Data Reliability

Embedded within the F100S framework is Emerson’s signature Multivariable Digital (MVD™) transmitter technology—an intelligent signal‑processing core transforming resonant tube dynamics into accurate digital mass, volume, and density values. MVD™ instantly compensates temperature variation, tube vibration, and pulsating flow interference through adaptive digital filters, achieving real‑time precision for both steady and transient flow conditions. Combined with Smart Meter Verification (SMV) diagnostics, users gain on‑demand confirmation of sensor health without interrupting operations. SMV identifies tube integrity, electronic stability, and calibration status, offering predictive alerts before mechanical fatigue or contamination arise. The integration of MVD™ and SMV guarantees sustained operational accuracy, extended maintenance intervals, and reduced lifecycle cost. Supporting batch processing with fast response rates and high‑speed sampling, this technology delivers transparent measurement feedback essential for automated industrial operations. Engineers can thus rely on the F100S to provide traceable data with digital certainty under intense process pressure, tough environmental exposure, and compliance criticality demanded by modern production environments.

Specialized Industrial Applications Across Global Process Sectors

The Rosemount F100S performs efficiently across diverse industries that demand accurate metrology under moderate to high pressure conditions. In chemical production, it monitors acid reactions, caustic transfers, and catalyst dosing within compact reactors requiring clean, drainable sensors. In food and beverage processing, it measures viscous liquids, dairy, and alcoholic beverages where purity and drainage minimize contamination risks. Pharmaceutical facilities depend upon F100S for solvent preparation and sterile flow control under high precision standards. Water and wastewater plants utilize it for chlorination, desalination, and recirculation systems requiring corrosion‑resistant components. Oil and gas terminals apply it for custody transfer and additive blending operations demanding certified measurement protocols. Its drainable configuration also suits marine and offshore fuel handling, protecting against saline erosion and vibration. With MID OIML R 117 and NTEP approval, the F100S ensures fiscal accuracy in commercial transactions. Across applications, the meter’s balanced mechanics, stainless integrity, and digital intelligence combine to provide absolute confidence in mass flow accountability throughout critical industrial infrastructure.

Reviews

There are no reviews yet.