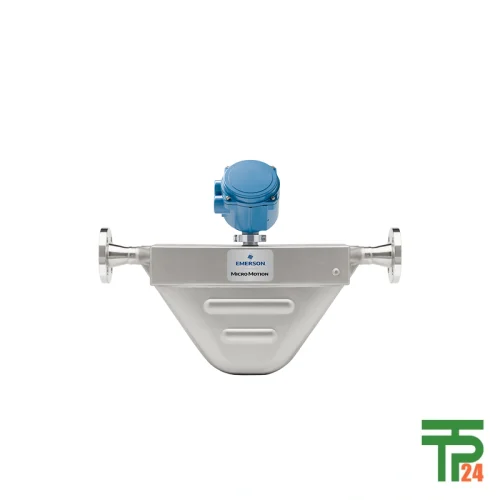

Emerson Micro Motion™ F150S Coriolis Meter

- Pressure Rating 100 barg Max

- Mass Flow Accuracy ± 0.10%

- Density Accuracy ± 0.001 g/cm³

- 4–20 mA + HART Output

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

Micro Motion™ F150S Coriolis Meter

High‑Performance Flow Measurement Through Stainless Precision Engineering

The Rosemount F150S Coriolis Flow Meter from Emerson represents the intersection of reliability, compact design, and technological excellence. Built from 316L Stainless Steel, it provides robust protection against corrosion, ensuring durability in hygienic and industrial settings where fluid purity and measurement stability are essential. With a maximum operating pressure of 1,450 psig (100 barg), the F150S maintains accuracy under challenging process conditions including high temperatures and dynamic flow variations. Its precise mass‑flow accuracy—±0.20 % in standard configuration, optionally refined to ±0.10 %—establishes it as one of the most reliable detection instruments in the process control industry. The F150S delivers exceptional repeatability (±0.050 % of rate), which guarantees continuity of results across extended operation cycles. Its drainable, compact design supports hygienic applications and facilitates safe cleaning procedures. Emerson has embedded stability and digital responsiveness at the heart of this meter’s design, creating a flow instrument ideal for modern facilities requiring uninterrupted, traceable flow data.

316L Stainless Steel Ensures Sanitary Strength And Longevity

Using 316L Stainless Steel, the F150S demonstrates remarkable chemical stability and hygiene suitability. This low‑carbon alloy resists pitting, rust formation, and micro‑contamination even during CIP (Clean‑in‑Place) or SIP (Steam‑in‑Place) sterilization cycles. It maintains mechanical integrity under thermal variation and chemical exposure, supporting industries such as food and beverage, pharmaceutical, water purification, and cosmetic manufacturing. Its smooth internal surface allows complete drainage, preventing bacterial retention or residue buildup that could compromise product quality. The material withstands acidic and saline environments where standard steels might corrode, preserving calibration and ensuring long‑term accuracy. Thanks to Emerson’s precise machining process, weld joints are polished and dead zones are eliminated—ideal for high‑purity operations involving ingredients, syrups, and medical solutions. The stainless build guarantees both sanitary excellence and extended lifecycle performance, giving end‑users a meter engineered for unwavering precision and cleanliness in critical process environments worldwide.

Advanced MVD™ Processing Delivers Dynamic Measurement Accuracy

At its core, the Rosemount F150S operates with Emerson’s MVD™ (Multivariable Digital) technology—an intelligent digital processing engine translating sensor motion into precise flow, density, and temperature data. This system filters unwanted noise from pipelines and mechanical vibrations, producing steady readings even during turbulent or pulsed flows. MVD™ instantly handles oscillation data at high frequency, enabling the fastest response times in batch or continuous monitoring. It supports mass and volume accuracy up to ±0.10 %, outperforming traditional analog meters in stability and resolution. Paired with Smart Meter Verification (SMV), the technology allows automatic health diagnostics of both sensor tubes and electronics, verifying calibration integrity without process interruption. Together, these features ensure sustainable measurement confidence and minimize downtime. By merging mechanical precision with digital foresight, Emerson provides a solution perfectly compatible with Industry 4.0 automation demands—allowing engineers access to verified, real‑time data streams that enhance productivity, efficiency, and quality assurance across global plants.

Hygienic And Industrial Applications Requiring Total Measurement Integrity

The versatile F150S Coriolis Meter serves a wide spectrum of industries requiring accurate and hygienic flow measurement. In pharmaceutical production, it enables precise dosing of active ingredients and sterile solvents, maintaining compliance with stringent purity standards. Food and beverage processors depend on its drainable design for syrup blending, ingredient proportioning, and milk standardization—where viscosity and temperature variation challenge ordinary meters. Water‑treatment facilities use the F150S for dosing additives and tracking purity levels efficiently. Cosmetic and personal‑care manufacturers apply it for cream filling and fragrance blending where uniform density ensures consistency. Beyond hygienic sectors, it operates in chemical and petrochemical laboratories, measuring solvents and low‑viscosity oils with dependable accuracy. The meter’s compact geometry simplifies installation in confined skids and modular manifolds, while its robust electronics sustain performance during extended production runs. This universal adaptability makes the F150S invaluable for facilities balancing strict hygiene with demanding throughput and analytical verification needs.

Reviews

There are no reviews yet.