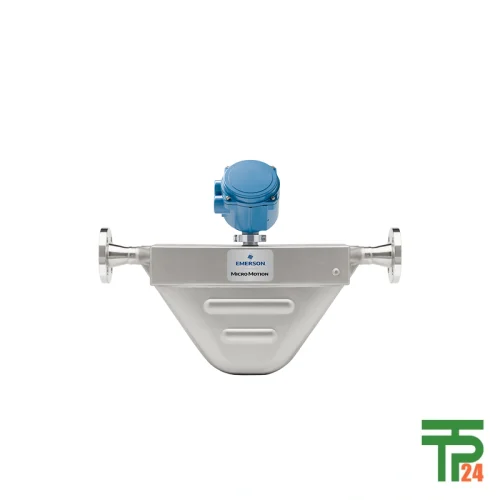

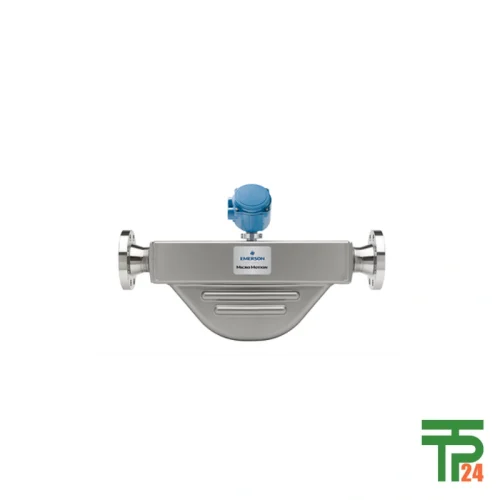

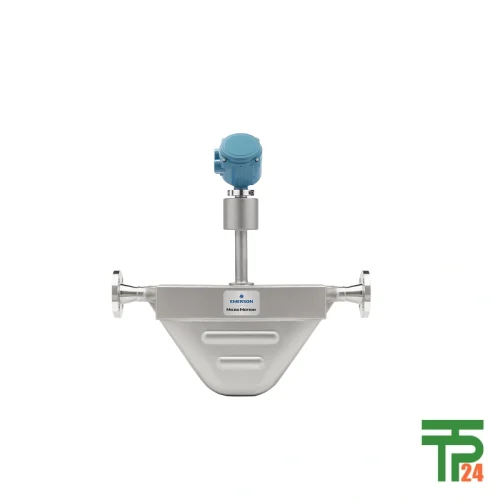

Emerson Micro Motion F200H Coriolis Meter,

- Pressure Rating 149 barg Max

- Mass Flow Accuracy ± 0.10%

- Density Accuracy ± 0.0005 g/cm³

- 4–20 mA + HART Output

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

Micro Motion F200H Coriolis Meter,

Advanced Coriolis Precision Through Nickel Alloy Design

The Rosemount F200H Coriolis Flow Meter exemplifies Emerson’s pursuit of absolute accuracy and reliability in high‑performance fluid measurement. Constructed from Nickel Alloy C22, renowned for corrosion resistance and structural endurance, this meter delivers precise mass, volume, and density data across complex industrial environments. Its robust, drainable architecture provides uninterrupted process integrity even under harsh chemical exposure and wide temperature variances. Supporting maximum working pressure up to 2,160 psig (149 barg), it guarantees stable operation within high‑pressure liquid or gas pipelines. The F200H achieves mass flow accuracy up to ± 0.10% (optional) and repeatability ± 0.05%, enabling dependable measurement consistency where reliability governs profitability and safety. Its refined twin‑tube system and optimized vibration isolation deliver accurate real‑time flow data independent of viscosity or temperature fluctuation. Emerson’s meticulous engineering yields a meter capable of sustaining analytical precision in continuous operations—outperforming traditional mechanical flow sensors across oil, chemical, and natural gas applications demanding sustained process control and compliance assurance.

Nickel Alloy C22 Delivering Corrosion‑Proof Longevity

The core strength of the F200H stems from its Nickel Alloy C22, a material engineered to excel under caustic, oxidizing, and chloride‑laden conditions. This alloy offers unmatched protection against pitting and crevice corrosion, ensuring measurement accuracy remains uncompromised even within concentrated acid streams or marine atmospheres. C22 retains its mechanical properties under extreme thermal gradients, maintaining metrological stability over prolonged exposure to reactive substances. Chemical plants utilize its resistance for sulfuric, hydrochloric, and nitric acid dosing, while offshore facilities rely on it to counteract saline degradation and high‑moisture environments. The alloy’s high tensile strength and fatigue endurance make it ideal for pressurized reactors and dense gas measurement lines. Its durability translates into extended instrument lifetime and reduced recalibration frequency, drastically lowering operational expense. By employing this alloy, Emerson guarantees that every F200H functions as a corrosion‑proof precision tool—preserving measurement integrity in operations where chemical purity and consistent instrument response define process quality and regulatory consistency.

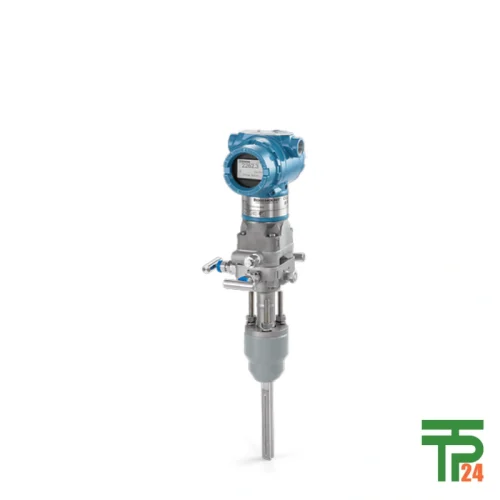

Digital MVD™ Transmitter Enabling Intelligent Measurement Control

Embedded within the F200H is Emerson’s leading Multivariable Digital (MVD™) transmitter, a high‑speed signal processor translating mechanical tube motion into accurate electronic flow computation. MVD™ instantly analyzes vibration phase shifts to determine simultaneous mass, density, and temperature data under varying process load. Advanced algorithmic filtering eliminates noise caused by pump pulsation or external vibration, guaranteeing linearity and repeatability across fluid states. Complementing MVD™ performance, the system integrates Smart Meter Verification (SMV) diagnostics—initiating automated health inspections of sensor integrity without stopping flow. SMV matches in‑process resonance profiles to factory baselines, detecting tube fatigue or contamination early. The transmitter also carries onboard historian and logging capabilities to record operational events, calibration data, and alarm history for complete traceability. Through these digital innovations, the F200H becomes more than a meter—it serves as a self‑validating analytical device providing continuous verification, efficiency insights, and predictive maintenance assurance directly aligned with Industry 4.0 smart process architectures.

Dedicated Applications Across Challenging Global Industries

The Rosemount F200H finds its purpose within critical industries that demand stable, precise metrology under high‑temperature and high‑pressure conditions. In petrochemical and refining operations, it supports high‑energy fractionation columns, pressurized blending circuits, and custody transfer analyses where fiscal accountability hinges on accurate mass readings. Chemical manufacturing plants deploy the F200H for solvent polymerization, oxidizer reactions, and caustic acid dosing lines requiring corrosion‑resistant instrumentation. Natural gas and LPG processing facilities depend on its verified performance for gaseous mass tracking in pipeline distribution or liquefaction modules. In marine and offshore fuel systems, it delivers stable readings amidst vibration, temperature shift, and saline intrusion. Pharmaceutical facilities utilize its clean drainable geometry for temperature‑controlled solvent and reagent dosing under sterile conditions. Even food and beverage industries benefit from precise syrup, alcohol, and oil metering while maintaining purity compliance. Across all fields, the F200H ensures repeatable measurement accuracy crucial to operational safety, commercial validation, and international custody transfer confidence.

Connectivity And Process Integration For Modern Automation

The F200H merges mechanical perfection with complete digital communication adaptability. Equipped with protocols like HART®, Modbus®, and FOUNDATION™ Fieldbus, it connects fluid measurement directly to supervisory DCS or PLC systems. A rotatable back‑lit LCD display allows real‑time visibility of flow and density data even under dim environments. Predictive diagnostic alerts warn operators of tube strain or flow anomalies before process disruption occurs. EMI‑shielded electronics deliver stability in noisy industrial zones, while compact wiring reduces installation complexity. Engineers can execute remote configuration, auto‑zero verification, and batch calibration through secure network channels, minimizing manual intervention. The onboard historian enables analytic comparison between historical and current readings, simplifying trend forecasting and calibration audits. With such connectivity, the F200H operates as both a sensor and analytical controller—strengthening automation frameworks through continuous transparency, digital responsiveness, and trusted signal fidelity across global flow measurement infrastructures.

Reviews

There are no reviews yet.