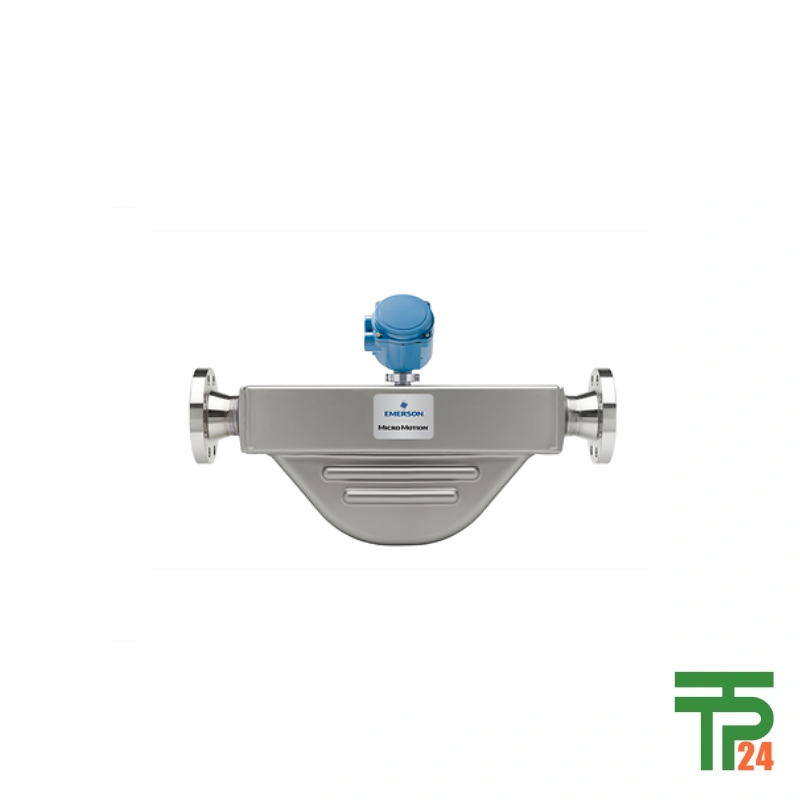

Emerson Micro Motion F300H Coriolis Meter

- Pressure Rating 149 barg Max

- Mass Flow Accuracy ± 0.10%

- Density Accuracy ± 0.0005 g/cm³

- 4–20 mA + HART Output

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

Micro Motion F300H Coriolis Meter

High‑Pressure Precision Through Nickel Alloy Engineering

The Rosemount F300H Coriolis Flow Meter by Emerson exemplifies the fusion of advanced engineering and material science to achieve long‑term measurement precision under extreme industrial conditions. Constructed from Nickel Alloy C‑22, this device delivers outstanding resistance against corrosive chemicals and maintains its geometry under tremendous stress and temperature. It operates efficiently in systems demanding a maximum working pressure of 2,160 psig (149 barg), offering both liquid and gas flow accuracy with exceptional repeatability. Standard liquid measurements reach ±0.20 % of rate, while optional configurations can achieve ±0.10 %—making it one of the most accurate industrial meters available globally. Its drainable, compact structure is optimized for hygienic applications and chemical purity. The F300H remains unaffected by process vibrations or thermal fluctuations, sustaining authentic data acquisition. Emerson’s commitment to reliability shines through every aspect of the F300H’s design, establishing it as a primary choice for operations that must maintain absolute precision under high‑pressure conditions and severe corrosive exposure.

Nickel Alloy C22 Ensuring Unmatched Corrosion Resistance

Every F300H is forged from Nickel Alloy C22, a metal known for its resilience against strong oxidizing agents, chlorides, and hot acid environments. This metallurgy offers exceptional immunity to pitting, crevice corrosion, and stress cracking—problems often encountered in stainless‑steel systems handling harsh media. High‑temperature acid plants, chemical reactor loops, and petrochemical oxidation units depend on this resistance to preserve sensor integrity over long operating lifespans. The material further enhances safety by preventing hydrogen embrittlement, ensuring stableness even in sour gas or aggressive hydrocarbon treatments. The C22 alloy promotes consistent calibration retention, minimizing drift across extensive pressure and temperature cycles. It retains aesthetic and mechanical integrity for decades, effectively eliminating the need for frequent replacements. This corrosion‑proof construction empowers engineers and operators to deploy the F300H in marine fuel handling, offshore injection skids, and acid neutralization lines, where system uptime and material purity must coexist without compromise.

MVD™ And Smart Meter Verification Synergy

Central to the meter’s intelligence is Emerson’s MVD™ (Multivariable Digital) transmitter and Smart Meter Verification (SMV) diagnostic suite—tools that redefine process insight and measurement health. MVD™ instantly computes mass, volume, and density by processing dual‑tube oscillations through complex algorithms that reject external vibration noise and temperature bias. The result is extraordinary signal fidelity with rapid response in batch and continuous flow scenarios. SMV complements this precision by continuously testing the mechanical and electronic condition of the meter, confirming calibration validity without interrupting fluid movement. These diagnostics reduce maintenance costs, bolster confidence in real‑time accuracy, and create robust traceability across regulated industries. An on‑board historian and logging system captures process data, error histories, and configuration events for auditing and quality management. Together, MVD™ and SMV elevate the F300H beyond a standard flow meter—it becomes a self‑verifying intelligence node, integrating seamlessly within predictive maintenance and Industry 4.0 automation frameworks across global manufacturing environments.

Industrial Applications Demanding Stability And Extreme Endurance

The Rosemount F300H Coriolis Meter finds purpose where few instruments can withstand the demands. In oil and gas operations, it monitors high‑pressure crude and condensate streams, validating custody transfer and supporting fiscal measurement in compliance with MID OIML R 117 standards. Chemical manufacturers utilize it for aggressive acid production, polymer feed monitoring, and solvent recycling processes requiring high‑temperature compatibility. Petrochemical refineries deploy F300H meters in catalyst dosing, high‑pressure hydrogenation, and reactor outlet verification—areas known for mechanical stress and corrosive attack. In marine and offshore installations, the meter excels in subsea injection and fuel transfer lines, where saltwater exposure and vibration are daily challenges. Power generation plants depend on its precise density measurement for boiler feed control and energy efficiency optimization. Across all these domains, the F300H delivers stable readings, high accountability, and long service life, providing valuable performance continuity where process failure could cause significant financial or environmental losses.

Reviews

There are no reviews yet.