Emerson Micro Motion FVM Fork Viscosity Meter

- Viscosity Range 0.5–20,000 cP

- Density Accuracy ±1 kg/m³

- Temperature Up To 392 °F

- 4–20 mA + HART® Output

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

Micro Motion FVM Fork Viscosity Meter

Advanced Multivariable Measurement For Complex Process Applications

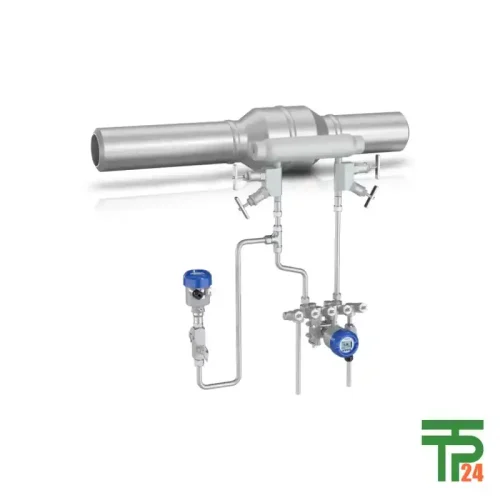

The Rosemount FVM Fork Viscosity Meter represents Emerson’s highest‑precision solution for simultaneous measurement of viscosity, density, and temperature, ensuring real‑time process insight within pipelines, bypass loops, and tanks. Its core design integrates high‑frequency mechanical resonance with digital signal interpretation, transforming vibration data into accurate viscosity values across a massive range—from 0.5 to 20,000 cP. Comparatively, density is measured within 0–3000 kg/m³ at an astounding accuracy of ±1 kg/m³ (±0.001 g/cm³). When coupled with temperature ranges up to 200 °C (392 °F), the instrument empowers operators to control product behavior under real process conditions rather than isolated laboratory tests. This multivariable capability permits inline real‑time monitoring for viscous liquids like lubricating oils, bitumen blends, pharmaceutical gels, and chemical polymers. An industrial engineer can deploy a single compact unit to replace three separate instruments—simplifying installation and reducing downtime while enhancing data trustworthiness for automated process algorithms that govern flow optimization and energy consumption.

Precision Engineering With Exceptional Measurement Accuracy Built‑In

Accuracy defines the Rosemount FVM’s global reputation. For fluids with viscosity between 0.5 and 10 cP, it offers precision to ±0.2 cP. Above this, each range—10 to 100 cP, 100 to 1000 cP, and 1000 to 20,000 cP—maintains ±1% full‑scale accuracy across operating conditions. Coupled with density accuracy of ±1 kg/m³, operators obtain laboratory‑grade results directly in the pipeline. It achieves these numbers through precisely tuned fork resonance and continuous digital frequency tracking, ensuring repeatability even across temperature shifts and pressure fluctuations. Short‑stem versions function from –50 to +200 °C, whereas long‑stem models operate from –40 to +150 °C, serving both cryogenic and high‑thermal applications. This unique temperature adaptability renders the FVM a perfect choice for bitumen monitoring, fuel blending, and polymerization control where precise viscosity profiling directly determines product quality. By delivering accurate multi‑parameter data in real time, the instrument drives better feedback control loops in DCS and PLC systems, fostering optimal mixing efficiency and energy management.

Corrosion‑Resistant Design Ensuring Unmatched Reliability Worldwide

The construction of the Rosemount FVM demonstrates Emerson’s commitment to long‑term durability in harsh environments. The entire wetted assembly is forged from 316L stainless steel, offering excellent resistance to acidic fluids and abrasive materials. The tine surface finish can be standard polished, DLC (Diamond‑Like Carbon) coated, or electro‑polished depending on service conditions—making the meter suitable for both food‑grade and petrochemical applications. The transmitter housing is available in polyurethane‑painted aluminum for cost‑sensitive projects or 316L stainless steel for full chemical resistance. All variants support operation within hazardous zones approved by ATEX, CSA, and IECEx standards. In application, these materials withstand thermal stress, chemical attack, and mechanical vibration, ensuring measurements remain stable year after year. Over time, plants save significantly on maintenance and replacement while preserving accuracy. Whether installed in a crude oil pipeline in the Middle East or a chocolate mixing loop in Germany, the same instrument delivers the same unwavering data assurance.

Intelligent Display Interface For On‑Site Configuration And Control

Operational visibility is a cornerstone of modern measurement, and the Rosemount FVM addresses it through a two‑line segmented LCD display that rotates in 90‑degree increments to optimize viewing posture during installation. A robust optical switch enables configuration in hazardous areas without removing covers or triggering sparks. The glass‑lens front resists chemical scratching while three multi‑color LEDs provide instant status reporting—green for normal operation, amber for warnings, red for critical alerts. Through this interface, users can view process variables, acknowledge alerts, and modify mA or RS‑485 outputs directly. Multi‑language support and Known Density Verification (KDV) add greater control and trust in measurement auditing. With these capabilities, technicians reduce commissioning time and address issues without external calibration equipment. It creates a human‑centred feedback loop—operators see, respond, and verify instantly, making density viscosity control a tangible part of daily plant management rather than an abstract data set read remotely.

Versatile Communication Protocols For Seamless System Integration

True industrial compatibility comes from adaptability, and the Rosemount FVM offers more communication choices than any instrument in its class. Depending on electronic options, the transmitter can feature one or two externally powered 4–20 mA outputs, where Channel A includes HART® digital protocol and Channel B provides a dedicated analog signal. It further supports a Time Period Signal (TPS), a Discrete Output, and Modbus / RS‑485 connection for integration into PLC and flow computer architectures. Plants utilizing FOUNDATION Fieldbus™ control systems can order the FVM with a remote‑mount 2700 processor, achieving complete fieldbus communication. This multitude of outputs simplifies network engineering—each meter can feed simultaneous data streams for flow, temperature, and density to multiple control systems adopted in parallel. With fast response rates and diagnostic alerts, integrators can build redundant signal loops that guard against data loss in high‑speed pipelines. No matter the protocol environment —chemical, oil & gas, pharma, or food processing—the Rosemount FVM communicates seamlessly without adaptors or signal degradation.

Real‑World Applications Delivering Unrivaled Operational Benefits

The versatility of the Rosemount FVM Fork Viscosity Meter positions it as a definitive instrument for industries where fluid characteristics dictate outcome. In refineries, it monitors lubrication oil and bitumen viscosity to optimize pump efficiency and reduce energy draw. Within chemical reactors, it tracks density and viscosity to manage polymerization rates and endothermic reactions. For food producers, the FVM ensures correct mixture consistency in syrups, chocolates, and edible oils, preventing batch waste and ensuring texture uniformity. In pharmaceutical facilities, it guarantees precise gel and ointment viscosity where medical efficacy relies on exact fluid behavior. Marine operators use it to monitor bunker‑fuel density for engine control and billing accuracy. Regardless of sector, the Rosemount FVM brings actionable data—allowing plants to adjust mixing, temperature, pressure, and flow automatically through smart control algorithms. Day after day, it redefines process efficiency from mechanical measurement to actual economic performance gains.

Reviews

There are no reviews yet.