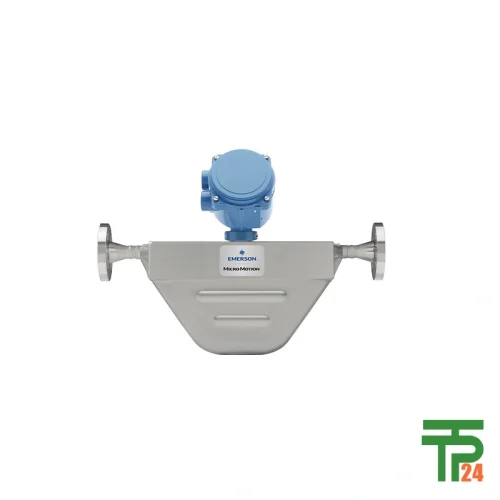

Emerson Micro Motion R050S Coriolis Meter

- Pressure Rating 100 barg Max

- Mass Accuracy ± 0.40 Percent

- Density Accuracy ± 0.003 g/cm³

- 4‑20 mA + HART Output

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

Micro Motion R050S Coriolis Meter

Compact Stainless Precision For Reliable Process Measurement

The Rosemount R050S Coriolis Flow Meter represents the next evolution of Emerson’s compact flow measurement technology, engineered for precision, dependability, and durability under demanding conditions. Constructed from 316L Stainless Steel, it resists corrosion and contamination across a vast range of chemical, hygienic, and utility applications, ensuring purity and stability. Designed to operate at pressures up to 1,450 psig (100 barg), the meter delivers consistent results under both standard and elevated temperature profiles. The R050S provides repeatable liquid mass accuracy of ±0.50 % (standard) or ±0.40 % (optional) and density resolution down to ±0.003 g/cm³. This balance of mechanical toughness and digital intelligence makes it ideal for general-purpose measurement requirements where reliability and accuracy cannot be compromised. Its drainable design simplifies cleaning, avoids cross-contamination, and allows effortless installation within constrained skids. For operations from laboratory to industrial scale, the R050S fulfills Emerson’s legacy of compact performance with maximum certification support and minimum maintenance.

316L Stainless Steel Ensures Long-Term Operational Integrity

With low-carbon 316L Stainless Steel construction, the Rosemount R050S offers versatile chemical compatibility and extended service life even in harsh environments. This high‑grade alloy withstands chemicals, saline solutions, and high temperatures, preventing pitting and oxidation that often degrade other materials. Its polished internal geometry allows complete drainage during product swaps—a critical hygienic feature for industries like pharmaceuticals, food and beverage, and personal care manufacturing. In chemical processing plants, the stainless steel housing endures contact with acids, bases, and solvents while maintaining calibration stability for custody‑critical measurements. The robustness of 316L enables reuse through multiple sanitization cycles without losing structural integrity, making the meter ideal for applications demanding both cleanliness and reliability. Emerson’s precision welding and surface finishing further enhance corrosion resistance, ensuring that each R050S delivers decades of dependable performance under varying process pressures and temperatures worldwide.

Integral Transmitter Streamlining Process Control And Integration

The R050S features an integral transmitter design that simplifies installation, data acquisition, and operation. This transmitter architecture provides flow‑variable‑only output, reducing wiring effort and saving significant configuration time. Operators can choose rugged transmitter options compatible with Class I Division 1 and Zone 1 hazardous environments, including versions with local operator interfaces for direct adjustments and diagnostics. Connectivity via HART®, Modbus®, and FOUNDATION™ Fieldbus ensures seamless integration into Distributed Control Systems (DCS) and Programmable Logic Controllers (PLC), enabling real‑time parameter monitoring and predictive maintenance programs. Emerson’s firmware automatically compensates for fluid temperature and density variations, ensuring accuracy and repeatability even under fluctuating process conditions. The intelligent electronics reduce calibration time and long-term cost, allowing plant engineers to focus on production optimization while maintaining absolute confidence in meter integrity and measured data fidelity.

Reviews

There are no reviews yet.