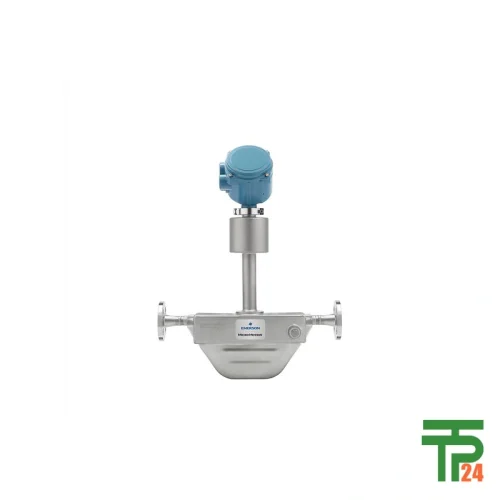

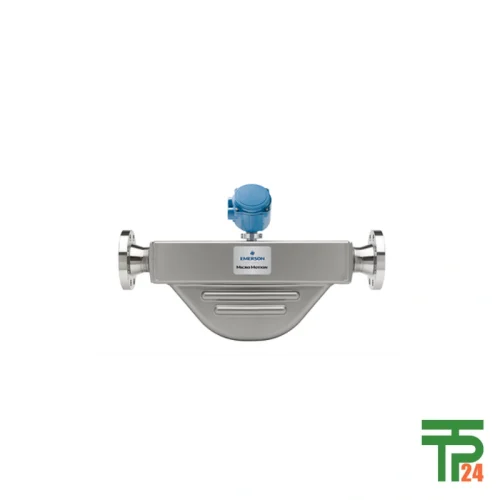

Emerson Micro Motion R100S Coriolis Meter

- Pressure Rating 100 barg Max

- Mass Accuracy ± 0.40 Percent

- Density Accuracy ± 0.003 g/cm³

- 4–20 mA + HART Output

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

Micro Motion R100S Coriolis Meter

Compact Stainless Strength For Consistent Flow Accuracy

The Rosemount R100S Coriolis Flow Meter from Emerson embodies high‑precision measurement in a compact, stainless‑steel design built for endurance, consistency, and global performance. Crafted from 316L Stainless Steel, this high‑pressure instrument resists corrosion and contamination while enabling dependable results up to 1,450 psig (100 barg). With a mass flow accuracy of ±0.50 % (standard) or ±0.40 % (optional), the R100S guarantees dependable mass‑to‑volume relationships in both liquid and gas systems. The drainable body assures cleanliness between batches, making it a favored choice for food‑grade, chemical, and laboratory applications. Emerson’s advanced signal processing and tube balancing deliver unmatched repeatability under temperature and pressure fluctuations, maintaining reliability during continuous or batch processes. Compact form allows seamless integration in confined skids, dosing modules, or research units where installation space is limited but performance expectations are uncompromised. The R100S reflects Emerson’s tradition of technological mastery—precision engineering designed to serve modern industry worldwide.

316L Stainless Steel Guarantees Durable Hygienic Operation

The R100S applies the integrity of 316L Stainless Steel, recognized for its superior resistance to acids, chlorides, and cleaning agents. It withstands repetitive sanitation procedures and high‑temperature cleaning cycles without susceptibility to corrosion or mechanical fatigue. The polished internal passage ensures drainability and prevents particle entrapment, an essential characteristic for hygienic production lines. This material choice supports applications like sterile pharmaceutical formulation, milk and dairy processing, flavor blending, and personal‑care emulsion mixing—industries requiring precise flow control with uncompromised cleanliness. In chemical reaction skids, 316L maintains calibration under contact with reactive fluids or corrosive acids, ensuring stability where process chemistry is volatile. Its low carbon content reduces intergranular corrosion, giving the R100S lasting mechanical strength and compliance with stringent regulatory environments. Emerson’s meticulous welding, surface passivation, and sensor balancing combine hygienic suitability with long‑term meter resiliency across diverse production facilities and continuous processing plants.

Smart Integral Transmitter Simplifies Data Control Networks

Emerson designed the R100S Integral Transmitter to streamline plant automation and facilitate precise digital communication. Its flow‑variable‑only architecture minimizes accessories and wiring, offering cost‑effective installation and quick commissioning. The transmitter supports HART®, Modbus®, and FOUNDATION™ Fieldbus protocols, permitting smooth integration with Distributed Control Systems (DCS) and programmable logic controllers (PLC) worldwide. Operators can use optional local‑operator interfaces for calibration, diagnostics, and verification directly at the field site. Rugged configurations certified for Class I Division 1 and Zone 1 allow deployment in hazardous or explosion‑rated facilities such as petrochemical refineries or fuel blending stations. Continuous monitoring of mass, density, and temperature gives technicians actionable feedback for predictive maintenance and batch quality validation. The R100S thereby converts process measurement into intelligent digital analytics—combining compact hardware reliability with Emerson’s advanced data integrity for dynamic industrial monitoring.

Specific Application Focus Across Global Industrial Sectors

The Rosemount R100S serves as a universal platform across multiple industries due to its versatility and calibration precision. In pharmaceutical manufacturing, it delivers accurate dosing for active ingredients, solvents, and buffer preparations where exact mass consistency affects product potency. Food and beverage plants employ it for syrup, chocolate, and dairy batching operations, leveraging the drainable design to meet hygienic standards. Water purification systems integrate R100S meters for precision dosing of disinfectants and regulating additives during filtration cycles. In chemical processing, it ensures repeatable flow control for acids, organics, and catalysts under high pressure without measurement drift. The cosmetics industry utilizes this meter for lotion, perfume, and emulsion blending, requiring meticulous density readings for texture control. Compact, stable, and corrosion‑resistant, the R100S suits laboratories where accurate flow characterization and calibration validation are routine daily tasks. From sanitation‑critical operations to rugged industrial fluid handling, the R100S delivers trustworthy results across all these application environments.

Extensive Certifications Strengthen Confidence And Global Compliance

Every Rosemount R100S meter comes authorized under international safety and performance regulations, ensuring seamless deployment anywhere in the world. It includes certifications such as CSA, ATEX, IECEx, and NEPSI, providing explosion protection for Class I Div 1 and Div 2 hazardous environments. The enclosure rating IP66/67 safeguards electronics against dust and pressurized water during sanitation or outdoor operation. NAMUR EMC compatibility guarantees immunity against electromagnetic interference in electrically dense plants. Emerson’s calibration practices trace to certified global standards, assuring traceability in fiscal or custody transfer applications. All documentation supports regulated industry audits and compliance validation under ISO and GMP practices. Combined, these certifications make the R100S truly international—accepted from Asian bioprocessing facilities to European chemical plants and North American refineries. Users can confidently standardize their measurement systems globally without specialized regional instrumentation, reducing procurement complexity and ensuring consistent operational legality worldwide.

Reviews

There are no reviews yet.