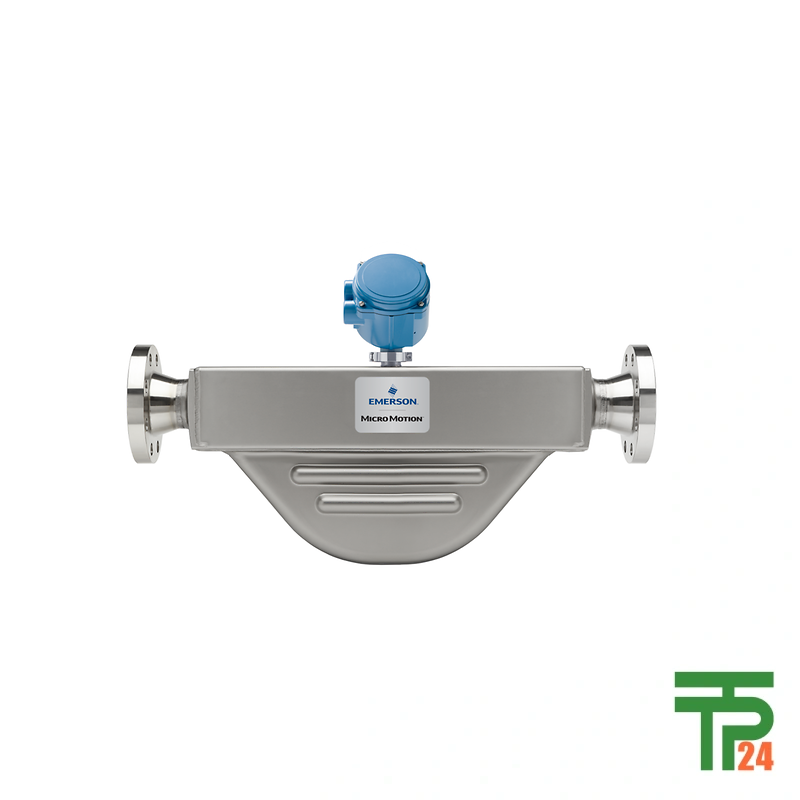

Emerson Micro Motion R300S Coriolis Meter

- Pressure Rating 100 barg Max

- Mass Accuracy ± 0.40 Percent

- Density Accuracy ± 0.003 g/cm³

- 4–20 mA + HART Output

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

Micro Motion R300S Coriolis Meter

Compact Stainless Durability For Accurate Flow Performance

The Rosemount R300S Coriolis Flow Meter exemplifies Emerson’s mastery in combining precision, durability, and compact engineering. Designed from 316L Stainless Steel, it withstands demanding industrial environments while ensuring consistent measurement under extreme pressures—up to 1,450 psig (100 barg). Its drainable geometry maintains hygienic operability for both clean and reactive processes, allowing rapid fluid changeover without residue. The R300S supports high‑performance liquid mass and volume flow measurement, maintaining stable calibration through temperature or density variation. Emerson’s advanced tube architecture drives repeatability and accuracy, critical for processes requiring dependable material accountability. With construction suited to most liquid or gas compositions, it delivers reliable throughput across sanitary, chemical, and general manufacturing contexts. Compactness simplifies system integration in existing pipelines or modular skids. Every aspect of the R300S is engineered to enhance precision while decreasing installation footprint—making it a true leader in reliable Coriolis measurement for global industry standards.

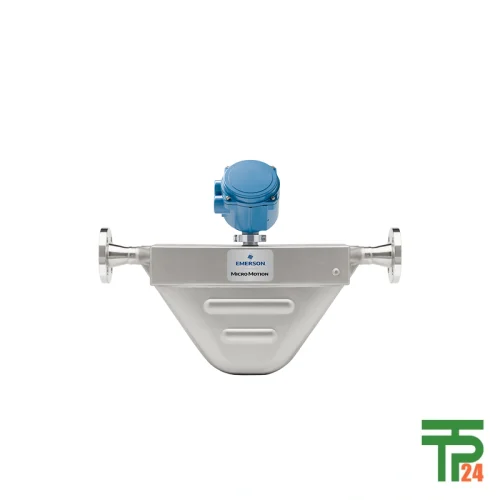

316L Stainless Design Ensures Reliable Clean Operation

Built entirely from 316L Stainless Steel, the R300S resists corrosion, cavitation, and material degradation over years of operation. The alloy’s stable surface properties prevent contamination, making the meter ideal for hygienic or pharmaceutical applications where sterility and product purity are essential. Food and beverage processors employ it to measure syrups, flavor concentrates, oils, and additives under cleaning cycles. Pharmaceutical facilities benefit from its effortless drainability for buffer or reagent transfer under CIP/SIP conditions. In chemical processing, its inert nature sustains integrity under exposure to acids, solvents, and oxidizing agents without calibration drift. For cosmetics manufacturers, the same smooth interiors deliver uniform emulsion batching, lotion blending, and fragrance dilution. Emerson’s 316L design delivers a lifetime of corrosion resistance and temperature stability, guaranteeing precise, reproducible flow measurements wherever cleanliness and strength simultaneously matter. Whether in sterile labs or heavy‑duty industrial plants, this stainless body defines durable, repeatable flow instrumentation performance.

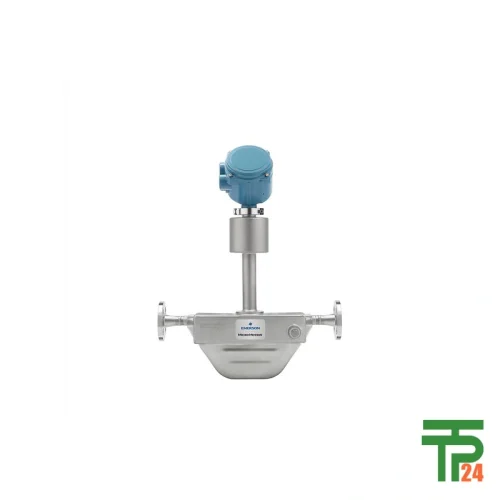

Integral Transmitter Architecture Simplifies Control Integration

The integral transmitter integrated in the R300S empowers direct command and control through advanced digital compatibility. It delivers a flow‑variable‑only architecture, reducing cabling, accessories, and installation cost while enabling immediate data feedback to supervisory systems. Operators leverage communication through HART®, Modbus®, and FOUNDATION™ Fieldbus protocols for seamless interaction with DCS or PLC environments. Ruggedized transmitter options include housings rated for Class I Division 1 and Zone 1, ensuring protection in potentially explosive locations. Optional local operator interfaces facilitate quick calibration and diagnostic operations directly from field level. Predictive diagnostics software continuously monitors performance parameters—temperature, vibration, and density—alerting maintenance before failure occurs. These integrated electronics merge simplicity and intelligence, translating mechanical precision into real‑time digital analysis. Through cost‑effective architecture and trouble‑free commissioning, the R300S delivers Emerson’s hallmark: technically sophisticated measurement in an extremely accessible form that supports global automation systems universally.

Versatile Applications Across Global Industrial Environments

The Rosemount R300S serves a broad spectrum of industry‑specific applications thanks to its high reliability and flexible configuration. In pharmaceutical production, the meter measures infusion solutions, active ingredients, and solvents requiring consistent dosing for potency assurance. Food and drink manufacturing facilities employ it for flavored syrups, dairy components, or energy drink batching under stringent hygiene protocols. Water treatment systems utilize its stability for chemical injection—chlorine, disinfectants, and additives—maintaining controlled dosing across varying flow rates. The chemical sector relies on its sturdy stainless structure for accurate feedstock balance in polymerization, catalyst blending, and solvent recycling. Personal‑care and cosmetics plants value its repeatable signal for uniform mixing of creams, fragrances, and emulsions under sterilization routines. Compact form and full drainability make R300S easily adaptable to mobile skids or confined platforms. Across every continent, this single instrument secures continuous production consistency with minimal calibration effort.

Reviews

There are no reviews yet.