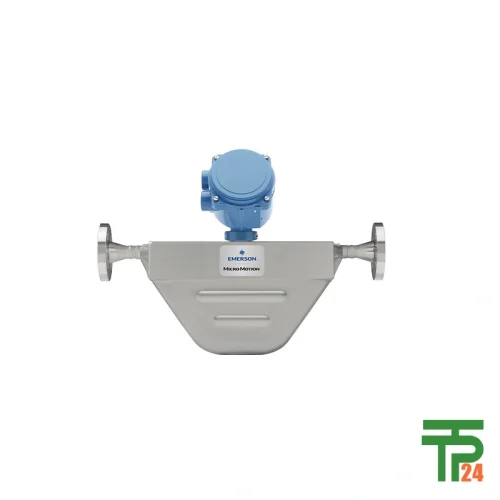

Emerson Micro Motion T075T Straight Tube Coriolis Meter

- Pressure Rating 100 barg Max

- Mass Accuracy ± 0.15 Percent

- Density Accuracy ± 0.002 g/cm³

- Titanium Grade 9 Construction

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

Micro Motion T075T Straight Tube Coriolis Meter

Titanium Hygienic Strength Delivering Unmatched Flow Accuracy

The Rosemount T075T Micro Motion Straight‑Tube Coriolis Meter is a Titanium Grade 9 engineered solution built for exceptional durability and uncompromising hygienic accuracy. Featuring a single straight‑tube design and a 32 Ra drainable surface finish, it ensures optimal cleanability while resisting product buildup in sanitary environments. Its plug‑resistant flow path prevents blockages, making it suitable for both low‑density gases and viscous liquids. With mass‑flow accuracy of ±0.15% for liquids and density accuracy of ±0.002 g/cm³, it delivers dependable readings under high‑pressure conditions up to 1,450 psig (100 barg). The streamlined flow architecture reduces pressure losses, maintains fluid integrity, and supports consistent process control from ingredient dosing to final packaging. By combining precision measurement capabilities with corrosion‑resistant titanium construction, Emerson’s T075T is a high‑performance Coriolis meter purpose‑engineered for global hygienic operations.

Comprehensive Certifications Enabling Worldwide Process Integration

The T075T meets rigorous certification standards including UL, CSA, ATEX, ASME, 3‑A, USDA, and EHEDG approvals, ensuring worldwide acceptability in both sanitary and hazardous areas. It satisfies CSA Class 1 Div 1 Groups C/D, ATEX Zone 1, and IECEx requirements, enabling safe use around flammable gases or vapors. Its IP66/67 ingress protection guarantees tolerance to high‑pressure washdowns and moisture exposure, critical in hygienic environments. These standards make the T075T deployable without modification in dairy facilities in Europe, biotech factories in Asia, and pharmaceutical cleanrooms in North America. Hygienic certifications, backed by a drainable straight‑tube design, confirm full CIP/SIP compatibility, ensuring operators can sterilize and reuse without disassembly. This broad compliance spectrum positions the T075T as a universal metering solution for multinational manufacturers aiming to standardize instrumentation across plants and regulatory regimes.

Integrated, Direct In‑Line Measurement Capabilities

The T075T delivers in‑line monitoring of mass flow, density, volume, concentration, and temperature within a single device. This integration reduces instrumentation complexity and minimizes potential error points within process lines. Its repeatability of ±0.05% empowers operators to replicate production results with confidence. Emerson offers diverse transmitter options supporting HART, Profibus‑PA, and FOUNDATION Fieldbus, ensuring easy network integration and advanced digital diagnostics. The meter’s fast dynamic response is ideal for batch blending, rapid recipe changes, or precision filling operations. Whether measuring CO₂ injection into beverage lines or controlling nutrient solutions in bioreactors, the T075T maintains calibration accuracy without requiring additional straight‑run pipe sections or flow conditioning plates—saving space and installation time. This consolidation of functionality brings unparalleled process visibility to operators demanding both hygienic assurance and measurement versatility.

Industry Applications Defining Its Global Relevance

In food and beverage operations, the T075T regulates syrup flow, dairy pasteurization, and carbonation dosing with consistent repeatability—even in plants running continuous CIP/SIP cycles. Pharmaceutical facilities depend on its titanium precision for metering active ingredients, solvents, and sterile buffer solutions. Biotechnology organizations deploy the T075T in fermentation systems, monitoring density changes to optimize microbial growth cycles. Dairy producers leverage its hygienic, drainable tube for cream mixing and yogurt batch control, ensuring no bacterial residue remains after cleaning. Cosmetics manufacturers benefit from its corrosion‑resistant titanium material when metering sensitive emulsions and oils. Across these use cases, the T075T enables compliance with industry regulations and delivers process stability essential for quality assurance, making it an irreplaceable component of sanitary and critical manufacturing systems globally.

Titanium Grade 9 Advantages for Aggressive Environments

The titanium composition ensures superior mechanical strength and natural corrosion resistance through its passive oxide film. In fruit juice production, it withstands prolonged contact with citric acids without pitting. In pharmaceutical sterilization, titanium endures high‑temperature steam and peracetic acid while retaining dimensional and calibration stability. Its high strength‑to‑weight ratio allows easier handling during installation and reduces mechanical stress on supports. The metal’s non‑reactive profile guarantees product purity by eliminating chemical interference or leaching risks. For facilities facing harsh cleaning regimes and corrosive media, the T075T’s titanium architecture delivers longevity, minimizing downtime and the costs of frequent sensor replacement. This durability translates directly into operational resilience across decades of service.

Maintenance and Operational Efficiency Improvements

The hygienic 32 Ra drainable straight‑tube ensures rapid cleaning cycles in CIP/SIP systems with complete removal of residues. The plug‑resistant design eliminates potential clogs and preserves meter responsiveness between runs. No straight‑run pipe sections or conditioning plates are required, streamlining installation on skids, compact modules, or retrofitted lines. Emerson’s Meter Verification tools allow remote performance checks, enabling predictive maintenance without halting production. Temperature measurement accuracy of ±1 °C supports critical heat‑sensitive processes such as pasteurization, vaccine preparation, or enzymatic reactions. These attributes reduce downtime, improve plant throughput, and maintain consistent product quality over extended production schedules. Efficiency gains are amplified in facilities operating multiple T075T units networked through Emerson’s intelligent diagnostic systems.

Reviews

There are no reviews yet.