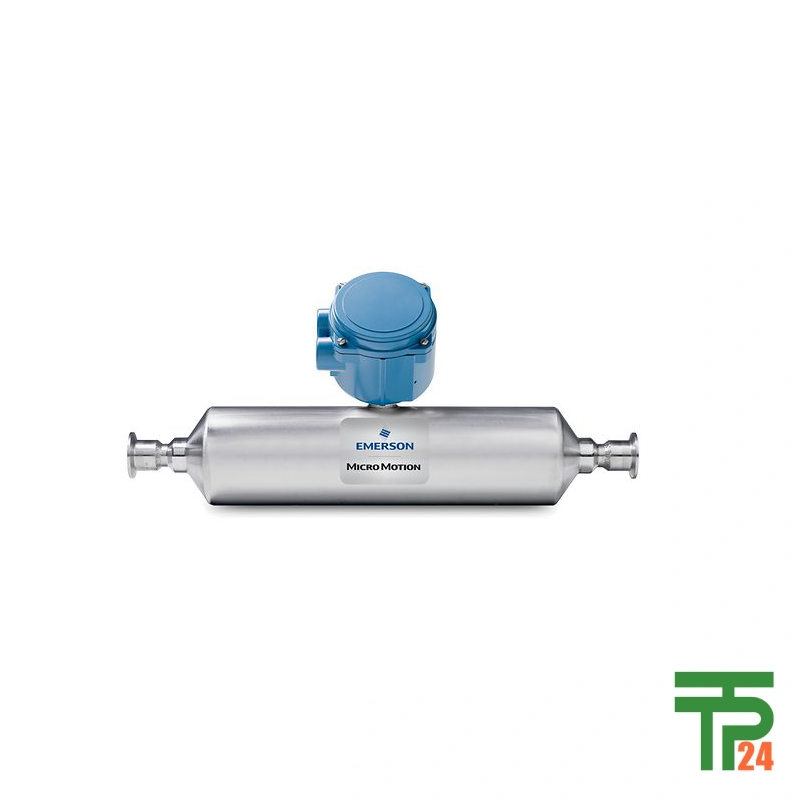

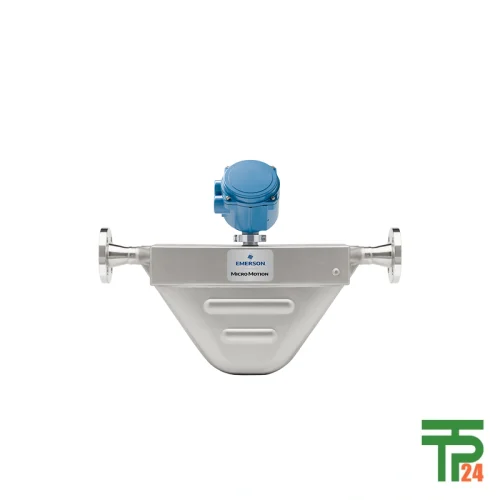

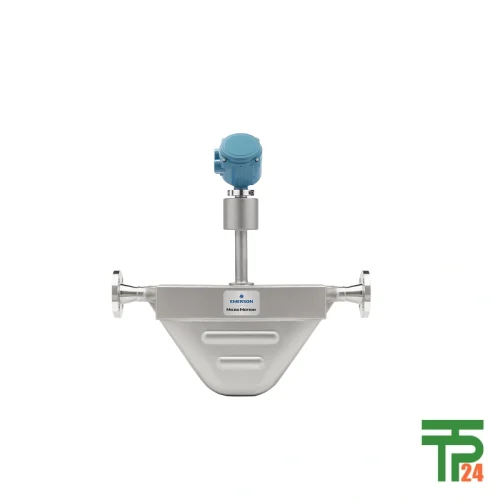

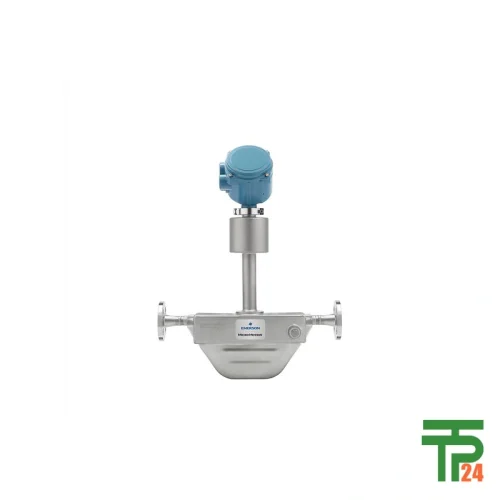

Emerson Micro Motion T100F Straight Tube Coriolis Meter

- Pressure Rating 100 barg Max

- Mass Accuracy ± 0.15 Percent

- Density Accuracy ± 0.002 g/cm³

- Titanium Grade 9 Construction

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

Micro Motion T100F Straight Tube Coriolis Meter

Titanium Hygienic Excellence With Precision Flow Accuracy

The Rosemount T100F Micro Motion Straight‑Tube Coriolis Meter represents the pinnacle of hygienic flow and density measurement for sanitary and demanding process environments. Constructed from Titanium Grade 9, it features a single straight‑tube architecture engineered for stability and long‑term accuracy under high‑pressure operations. With an ultra‑smooth 15 Ra surface finish, this meter is fully drainable and designed with a plug‑resistant flow path to prevent sediment accumulation or blockage. Operating at pressures up to 1,450 psig (100 barg), it delivers mass‑flow accuracy of ±0.15% and density accuracy of ±0.002 g/cm³, ensuring superior readings for liquids and gases alike. The robust titanium structure not only resists corrosion but also preserves product purity, making the T100F indispensable where cleanliness, precision, and chemical compatibility intersect.

Global Compliance Through Industry‑Recognized Certifications

The T100F carries an extensive range of international certifications and approvals, including UL, CSA, ATEX, ASME, 3‑A, USDA, and EHEDG. Each certification validates its reliability in both hazardous locations and sanitary installations, ensuring confidence for operators worldwide. It’s compliant with CSA Class 1 Div 1 Groups C and D, ATEX Zone 1, and IECEx protocols, while its IP66/67 rating guarantees resilience against moisture, dust, and high‑pressure washdowns. The device fulfills strict hygienic design standards under ASME BPE and the EHEDG cleanability specification. These endorsements allow the meter’s use across a global network of industries—from European dairy processing lines to Southeast Asian pharmaceutical crystallization facilities—without requiring local adaptation or additional compliance validation.

Multi‑Variable Measurement Integrated Into One Device

The T100F’s smart design achieves direct, simultaneous measurement of mass flow, volume, density, concentration, and temperature, consolidating five critical process parameters into one unit. Its repeatability of ±0.05% guarantees steady results even with fluctuating process conditions or batch transitions. Emerson’s advanced transmitter portfolio supports HART, Profibus‑PA, and FOUNDATION Fieldbus, ensuring interoperability with any modern automation network. Process engineers benefit from quick configuration, transferable calibration data, and diagnostic capabilities like Smart Meter Verification, reducing calibration downtime and maintenance costs. This multi‑variable integration minimizes piping complexity and enhances responsiveness, delivering complete process visibility essential to modern, data‑driven manufacturing environments.

Industrial Applications Across Diverse Hygienic Sectors

The Rosemount T100F serves as a cornerstone for high‑purity production systems where fluid integrity cannot be compromised. In food and beverage industries, it precisely measures syrup dosing, carbonated drink formulation, and dairy pasteurization with full CIP/SIP compatibility. In pharmaceutical operations, the meter regulates solvent transfers, buffer preparation, and bioreactor feeds, ensuring traceable density control during sterile production. Biotechnological facilities employ it for enzyme injections and nutrient monitoring, maintaining consistency across fermentation cycles. Cosmetics manufacturers leverage the T100F for blending high‑viscosity emulsions and essential oils, where contamination prevention is vital. In specialty chemical plants, titanium resistance ensures safe monitoring of acidic or oxidative fluids—demonstrating its unmatched versatility across hygienic and corrosive process landscapes worldwide.

Titanium Grade 9 Reliability And Corrosion Resistance

Titanium Grade 9—its defining material—delivers outstanding corrosion prevention through a protective oxide layer, resisting acids, chlorides, and sterilization chemicals that degrade conventional stainless steel. The alloy’s strength‑to‑weight ratio allows structural integrity under high pressure while keeping installation light and manageable. In dairy CIP systems using caustic and acidic cleaning agents, titanium ensures longevity free from surface degradation. In pharmaceutical sterilization, it withstands high‑temperature steam cycles without losing calibration accuracy. The non‑reactive nature of the metal safeguards product composition, ensuring that measured fluids remain uncontaminated. This combination of structural endurance and chemical inertness reinforces the T100F as a permanent, low‑maintenance solution for facilities pursuing uncompromised sanitary precision.

Efficient Cleaning And Installation For Daily Operations

Designed for easy Clean‑in‑Place (CIP) and Steam‑in‑Place (SIP) operations, the T100F minimizes maintenance intervals between production cycles. Its straight‑tube geometry eliminates flow conditioning requirements, allowing installations in tight spaces without long inlet runs. The plug‑resistant path speeds drainage and prevents fouling when switching between product types. Emerson’s diagnostics allow predictive maintenance and proactive calibration verification while the line continues running—saving valuable uptime. With accurate temperature measurement within ±1 °C, processors can safely control thermal‑sensitive fluid transfers. This seamless maintainability translates into greater asset reliability, lower water and detergent consumption, and optimized cleaning efficiency—properties highly valued in fast‑paced hygienic manufacturing environments.

Reviews

There are no reviews yet.