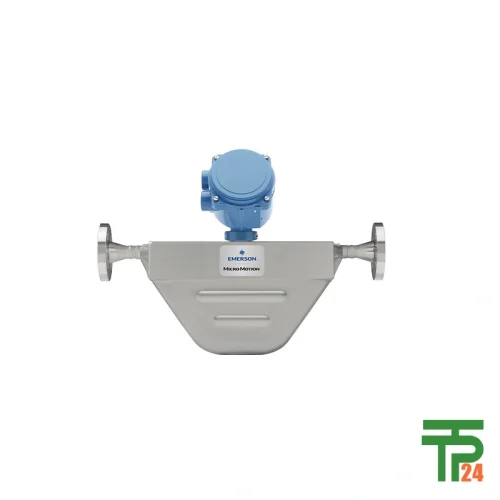

Emerson Micro Motion TA025T Coriolis Meter

- Pressure Rating 40 barg Max

- Mass Accuracy ± 0.10 Percent

- Density Accuracy ± 0.001 g/cm³

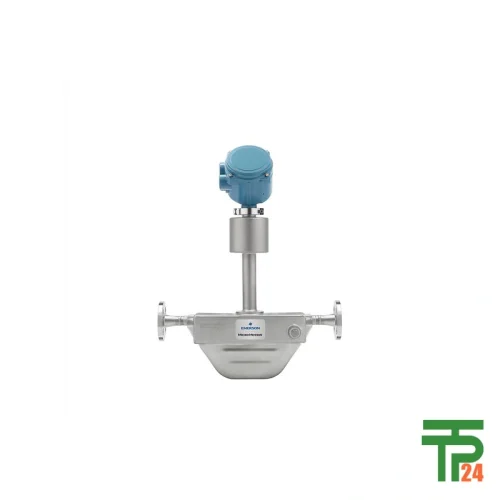

- Uses 5700 Nine‑Wire Transmitter

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

Micro Motion TA025T Coriolis Meter

Tantalum Precision Designed For Extreme Corrosive Measurement

The Rosemount TA025T Coriolis Flow Meter by Emerson defines excellence in measuring highly corrosive fluids under precision‑critical conditions. Constructed of tantalum‑wetted components, it provides a level of resistance that surpasses stainless steel, nickel, and super‑alloys, enabling operation within chemical environments where other materials deteriorate. This device achieves mass flow accuracy of ±0.10 percent and repeatability of ±0.05 percent, maintaining reliable performance across extreme temperature and pressure variations. It ensures volume flow accuracy ±0.10 percent, protecting critical process yields through consistent quality control. With a density accuracy of ±0.001 g/cm³ and a pressure rating up to 580 psig (40 barg), the TA025T becomes indispensable for laboratories and industrial plants demanding absolute measurement integrity. Emerson’s advanced Coriolis architecture embedded within the TA025T establishes stable tube resonance unaffected by vibration, offering robust results and confidence in processes requiring precision under corrosive attack conditions.

Tantalum Technology Securing Unmatched Chemical Resistance Reliability

The TA025T owes its enduring performance to tantalum’s unique metallurgical properties—exceptional resistance against acids, halogens, and oxidizers. Its non‑reactive composition safeguards measurement tubes exposed to substances like hydrochloric, nitric, hydrofluoric, and sulfuric acids. Chemical engineers value this resistance because tantalum resists penetration even from boiling acid mixtures, ensuring unlimited operational longevity. Pharmaceutical manufacturers utilize the TA025T for acid titration, buffer formulation, and reagent control, crucial for maintaining consistent drug batch chemistry. Semiconductor fabricators trust it for hydrofluoric‑acid flow control during wafer etching and rinse operations where micro‑level precision determines circuit yield. In metal refining and electroplating processes, the TA025T maintains flow equilibrium of nickel and gold electrolytes, unaffected by corrosive bath vapors. Catalyst production plants profit from its ability to measure chlorinated intermediates accurately. Across every chemical discipline—from research reactors to acid recovery lines—the TA025T delivers uncompromising resistance reliability matched to pure measurement precision.

Precision Measurement Enhanced By Advanced 5700 Transmitter Intelligence

The Rosemount TA025T comes exclusively combined with Emerson’s 5700 nine‑wire transmitter, an intelligent digital platform integrating Smart Meter Verification and on‑board historian logging systems. This transmitter allows real‑time monitoring of performance trends, verifying sensor integrity without process interruption. The historian records flow history, density changes, and temperature profiles, supporting predictive maintenance strategies across corrosive service environments. Output protocols such as HART®, Modbus®, and FOUNDATION™ Fieldbus facilitate seamless connection into global automation frameworks. Engineers leverage Smart Meter Verification to compare live tube signature curves with baseline calibration, guaranteeing precision retention over long operational cycles. Furthermore, the 5700 transmitter enhances measurement integrity by minimizing drift through continuous self‑diagnostics. These combined electronics transform the TA025T into an intelligent measurement node—capable not only of providing flow data but also of ensuring process transparency, safety, and accountability across complex corrosive fluid systems worldwide.

Dedicated Industrial Applications Across Corrosive Chemical Fields

The TA025T Coriolis Meter demonstrates exceptional applicability across industries confronted by aggressive chemical challenges. Within acid production plants, it measures continuous streams of sulfuric or nitric acid under pressures up to 40 barg, ensuring accurate yield control and emissions optimization. Pharmaceutical organizations use it to dose corrosive intermediates and acids in experimental synthesis laboratories where reagent precision defines compound success. In semiconductor manufacturing, it governs acid‑etch and cleaning flows, handling hydrofluoric and hydrochloric mixtures with unmatched measurement stability to maintain wafer purity. Metal surface processing plants depend on it for plating solutions and acid regeneration streams, preserving consistent composition of electrolytes. Fine‑chemical and catalyst industries employ the TA025T for density verification of halogen‑based reactants. Even research institutes adopt it for corrosive material characterization. These application domains prove TA025T’s vital role—bridging safety, repeatability, and productivity in every facility challenged by aggressive circulatory chemistry.

Certification Guarantees Safe Global Deployment And Compliance

Engineered for worldwide deployment, Emerson’s TA025T Coriolis Flow Meter is certified under CSA, ATEX, and IECEx approvals—granting operational clearance across explosive and hazardous chemical environments. These endorsements ensure compliance in Class I Division 1 and Zone 1 regions, where reactive gases or acids expose equipment to ignition risk. Its transmitter housing provides moisture‑proof sealing, maintaining insulation integrity even amid acid mist or thermal fluctuations. Every TA025T passes rigorous calibration traceable to international metrological standards—guaranteeing legal reliability in regulated measurement applications. The certifications also ease integration for multinational plants: once installed, no supplemental approvals are required for regional conformity. Emerson’s strict testing and documentation allow customers—from European acid processors to Asian pharmaceuticals—to operate with full assurance of safety, legitimacy, and sustained performance excellence backed by globally recognized engineering quality.

Reviews

There are no reviews yet.