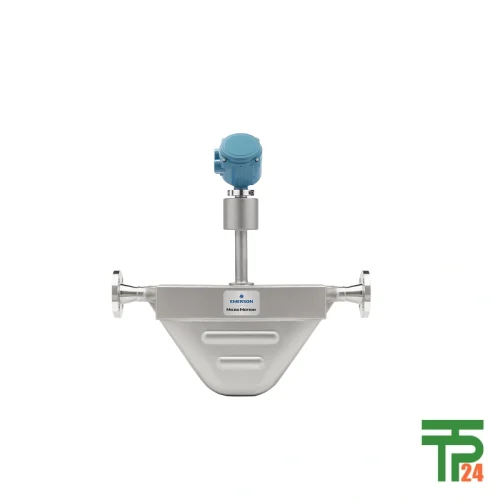

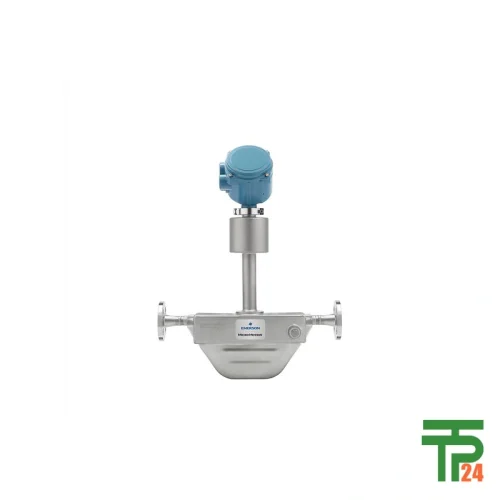

Emerson Micro Motion TA050T Coriolis Meter

- Pressure Rating 40 barg Max

- Mass Accuracy ± 0.10 Percent

- Density Accuracy ± 0.001 g/cm³

- Uses 5700 Nine‑Wire Transmitter

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

Micro Motion TA050T Coriolis Meter

Tantalum Construction Built For Extreme Corrosive Reliability

The Rosemount TA050T Coriolis Flow Meter stands as Emerson’s premier solution for corrosive service environments demanding unparalleled precision and endurance. Engineered from tantalum‑wetted components, this instrument offers complete resistance to destructive chemical agents that rapidly deteriorate conventional materials such as stainless steel or nickel alloys. Designed precisely for the toughest chemical systems, it delivers mass flow accuracy ±0.10 percent, repeatability 0.05 percent, and superior density accuracy ±0.001 g/cm³. These specifications make the TA050T exceedingly reliable for continuous process control where minute deviations can compromise product yield or safety. Supporting pressures up to 40 barg (580 psig), its rugged tube architecture prevents fatigue and distortion during sustained corrosive exposure. Emerson’s advanced vibration isolation method ensures stable Coriolis oscillation, transforming chemical instability into predictable, traceable data. This tantalum innovation defines industrial precision where corrosion is a permanent challenge, setting new standards for operational integrity and durable process measurement performance.

Tantalum Excellence Delivering Immunity In Corrosive Chemistry

The TA050T owes its resilience to the molecular strength and inert nature of tantalum. This rare metal resists attack from nearly every known acid, including hydrofluoric, hydrochloric, nitric, and sulfuric mixtures—even at elevated temperatures. Its non‑reactive surface prevents contamination and extends meter lifespan beyond typical alloy alternatives. Chemical manufacturing plants employ the TA050T in acid production and concentration systems, where long‑term measurement stability defines operational profitability. Pharmaceutical facilities integrate it for reagent titration and buffer preparation, ensuring laboratory‑grade purity and reproducible dosing. In semiconductor fabrication, it manages ultra‑pure acid flow through wafer‑etching and cleaning stages demanding zero impurities. Metal finishing operations rely on it for electrolyte control within plating baths. Across petrochemical units, it tracks halogenated catalyst mixtures under severe conditions. The TA050T transforms seemingly impossible corrosive streams into accurately measurable flow data, empowering chemical engineers to operate with confidence and unparalleled repeatability even under the universe’s toughest acid regimes.

Smart Integration With Emerson 5700 Nine‑Wire Transmitter

The Rosemount TA050T operates solely with Emerson’s 5700 nine‑wire transmitter, creating a fusion of mechanical precision and digital intelligence. This transmitter employs robust signal conditioning algorithms, delivering true mass, volume, density, and temperature readings in real time. Its Smart Meter Verification system evaluates sensor health, comparing mechanical response signatures with baseline calibration to assure measurement validity without halting production. Embedded on‑board historian and logging features record detailed process data—ideal for quality certification, trending analysis, and regulatory audits. Communication options include HART®, Modbus®, and FOUNDATION™ Fieldbus, enabling smooth integration into distributed control systems and Industry 4.0 frameworks. The synergy between tantalum sensor construction and advanced digital analytics gives engineers the ability to monitor reactive processes remotely, diagnosing corrosion or flow abnormalities instantly. Emerson’s combined design thus modernizes chemical measurement—transforming the TA050T into a self‑aware, high‑fidelity process instrument indispensable for digital plant ecosystems managing aggressive fluid reactions worldwide.

Corrosive Service Applications Across Multiple Industrial Sectors

The TA050T Coriolis Meter is tailored for industries where corrosion and precision intersect. Acid processing plants utilize it to measure sulfuric, hydrochloric, and nitric acid flows during refinement and concentration. Pharmaceutical engineers integrate the meter into batch reactors and neutralization tanks, achieving true dosage repeatability with no contamination. In semiconductor manufacturing, TA050T governs hydrofluoric acid delivery networks crucial to micro‑etch and wafer cleaning processes. Metal plating facilities depend on precise compensation of electrolyte temperature and density to maintain surface coating consistency. Petrochemical reactors employ it for halogen reaction monitoring, catalyst dosing, and yield control under pressurized environments. It also proves essential in research laboratories for acid titration, nuclear material dissolution, or corrosion‑rate verification testing. Wherever active chemistry demands uncompromising measurement integrity, the TA050T assures safe, precise, and repeatable monitoring—binding together performance reliability and lifetime stability that only tantalum instrumentation can deliver.

Reviews

There are no reviews yet.