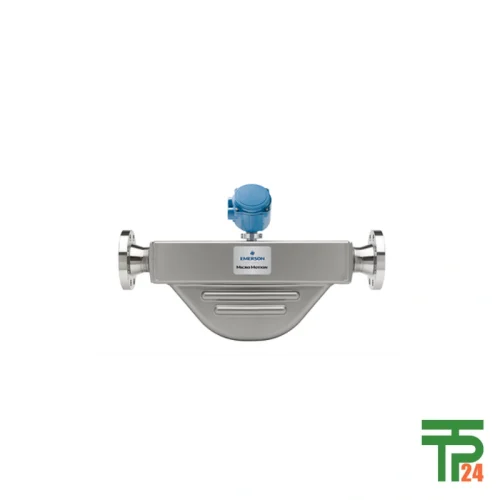

Emerson Micro Motion TA200T Coriolis Meter,

- Pressure Rating 40 barg Max

- Mass Accuracy ± 0.10 Percent

- Density Accuracy ± 0.001 g/cm³

- Uses 5700 Nine‑Wire Transmitter

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

Micro Motion TA200T Coriolis Meter,

Tantalum Construction Delivering Ultimate Corrosive-Service Reliability

The Rosemount TA200T Coriolis Flow Meter stands unrivaled among advanced measurement technologies for corrosive-service industries, designed with tantalum‑wetted components that guarantee absolute immunity against chemical degradation. Developed for precision mass, volume, and density measurement, the TA200T provides mass flow accuracy of ±0.10%, maintaining exceptional repeatability at 0.05%, even when exposed to extremely reactive fluids such as hydrofluoric, nitric, and sulfuric acids. It operates safely under pressures up to 40 barg (580 psig)—performance unmatched by conventional alloys. Emerson engineered the meter to deliver long‑term measurement resilience, combining finite element tube modeling with precision vibration‑isolation architecture, making it immune to process shock, pulsation, or temperature fluctuation. The TA200T represents the apex of measurement stability for corrosive processing, providing sustainable accuracy and indefinite service life where durability and chemical resistance are critical to plant success.

Chemical Resilience Enabled Through Pure Tantalum Wetted Components

Tantalum’s natural oxide layer functions as a permanent barrier against the most corrosive agents, giving the Rosemount TA200T a lifetime resistance to attack by acids and halogen-based reagents. This construction allows continuous operation in mixed‑phase acidic reactions that would rapidly destroy stainless‑steel or nickel instruments. Chemical manufacturers utilize the TA200T for acid blending, chlorine dosing, and high‑purity reactor feed lines, where uninterrupted flow accuracy ensures strict process quality. Pharmaceutical synthetic platforms rely on its inert purity for catalyst metering and solvent neutralization control, preserving reaction integrity free from metallic ion interference. Semiconductor fabrication plants value the TA200T for hydrofluoric acid and strong oxidizer delivery across wafer‑etch systems, eliminating contamination risk. Metal finishing operations leverage it for precise electrolyte balancing during electro‑deposition cycles, maintaining uniform plating across batches. Wherever extreme chemistry exists, tantalum ensures perpetual protection—turning the TA200T into the cornerstone of accuracy in hostile fluid environments.

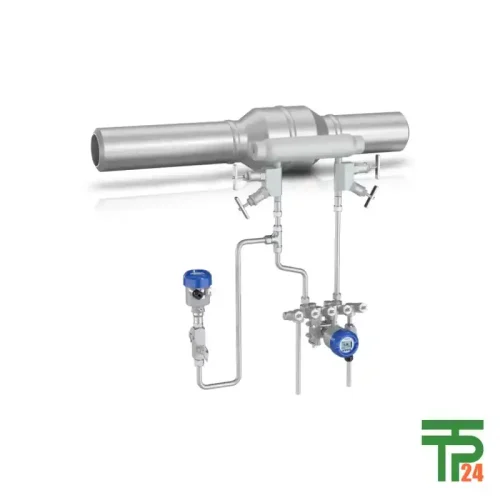

Engineered Precision Through Emerson’s 5700 Nine‑Wire Transmitter

Exclusively paired with Emerson’s Model 5700 Nine‑Wire Transmitter, the TA200T offers unmatched intelligence, self‑diagnostics, and digital clarity. The transmitter executes continuous Smart Meter Verification tests—an Emerson‑patented process that confirms mechanical and electronic health against factory baselines without interrupting flow. This self-assurance system empowers operators to verify measurement integrity in real time, eliminating costly shutdowns for recalibration. Beyond verification, the 5700 integrates robust on‑board historian and process logging, capturing every operational parameter for regulatory audits and long-term trend analysis. Through communication protocols including HART®, Modbus®, and FOUNDATION™ Fieldbus, facilities tie the TA200T directly into distributed control networks. Each transmitter‑sensor pair functions as a unified analytical instrument, promoting predictive maintenance and cloud‑ready reporting across global chemical ecosystems. Emerson’s integration transforms corrosive‑service meters into intelligent, self‑aware assets capable of diagnosing, recording, and optimizing their own performance.

Industrial Applications Requiring Exceptional Corrosive Fluid Control

The Rosemount TA200T Coriolis Meter advances precision across multiple industries reliant on corrosive fluid measurement. In acid manufacturing, it supervises concentrated sulfuric and nitric acid output flows for consistent purity and production efficiency. Pharmaceutical plants employ it for ingredient metering in complex reaction dosing systems, safeguarding drug consistency. Within semiconductor clean‑room operations, the TA200T guarantees uniform acid delivery for wafer etching and oxide removal where contamination elimination defines yield success. Metal plating and refining facilities use it for electrolyte density control critical to uniform coating deposition. Finally, petrochemical reactors integrate the TA200T in halogen‑charge dosing lines to maintain stoichiometric balance and optimal catalyst exposure. Each scenario reflects one vital truth—precision survives only where corrosion cannot penetrate. With tantalum at its heart, the TA200T remains the unrivaled solution for industries battling chemical aggression yet demanding the highest analytic certainty from every flow cycle.

Reviews

There are no reviews yet.