Rosemount™ 3410 Series Electronics for Gas Ultrasonic Flow Meters

- Power Input 10.4 To 36 VDC

- Temperature Range ‑40 To +60 °C

- Mount Option Integral Or Remote

- Material Aluminum Or Stainless Steel

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

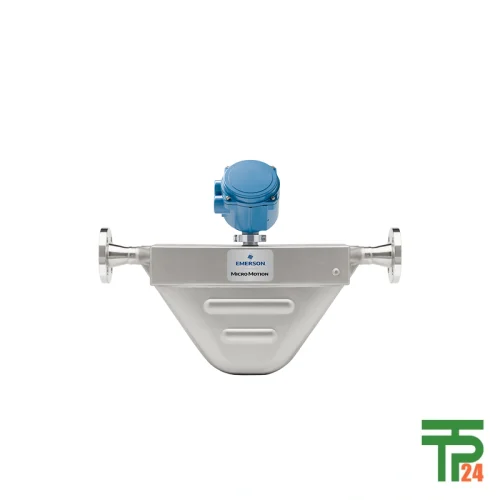

Rosemount™ 3410 Series Electronics for Gas Ultrasonic Flow Meters

Next‑Generation Electronics Enabling Superior Gas Measurement

The Rosemount™ 3410 Series Electronics for Gas Ultrasonic Flow Meters redefine accuracy and responsiveness in gas flow measurement technology. Built upon Emerson’s decades‑long expertise, the 3410 represents a leap forward in signal processing speed and environmental resilience. It reads, interprets, and communicates evolving flow dynamics within seconds, ensuring continuous control in operational environments where precision directly impacts profitability. Integrating advanced computational algorithms, the system enhances linearity and repeatability across the entire calibrated flow range—even under low‑flow conditions that traditionally challenge ultrasonic metering. Designed to seamlessly function with all Rosemount gas ultrasonic meter models, it ensures backward compatibility without sacrificing new‑generation functionality. The electronics achieve unmatched accuracy by combining ultra‑stable processing boards with adaptive measurement logic that maintains calibration certainty throughout the meter’s lifespan—empowering industries to operate smarter, faster, and safer in their flow management systems.

Enhanced Processing Architecture Delivering Dependable Performance Stability

At the heart of every Rosemount 3410 Electronics Module lies an optimized digital processor delivering precision computation under all operating scenarios. Running at 8 watts typical (15 watts max), it efficiently captures ultrasonic travel times to translate them into exact volumetric gas flow values. The wide power acceptance range of 10.4 VDC to 36 VDC allows simplified integration across various instrumentation networks and energy infrastructures. With advanced noise discrimination and transient (lightning) protection, the 3410 safeguards meter data integrity even during severe industrial electrical disturbances. The electronics compartment—available in aluminum or stainless‑steel materials—offers rigidity and corrosion resistance that thrive in refineries, gas compression stations, or metering skids exposed to environmental stress. Emerson’s system design minimizes thermal drift, ensuring stable performance in temperatures varying from ‑40 °C to +60 °C, delivering uninterrupted reliability in deserts, offshore rigs, cryogenic terminals, and high‑altitude measurement points alike.

Simplified Design Maximizing Maintenance Efficiency And Longevity

One of the defining advantages of the Rosemount 3410 platform is its modular construction that dramatically reduces maintenance complexity. Instead of replacing entire boards during service operations, users can exchange discrete functional modules such as CPU, I/O, intrinsic safety, or power supply boards individually. This plug‑and‑play structure cuts downtime significantly and lowers lifecycle cost. The 3410 further incorporates Smart Meter Verification Basic, a firmware‑integrated diagnostic feature that provides continuous assurance of ultrasonic path integrity. Plant operators receive instant verification of meter health, minimizing troubleshooting time and supporting predictive maintenance schedules. Continuous firmware evolution through Emerson updates enables expanded functionality without replacing hardware—ensuring futureproof investment protection. In heavy industrial settings, this modular approach allows fast turnaround, empowering teams to restore measurement continuity while maintaining full compliance with fiscal and reporting accuracy demands.

Comprehensive Visibility With Advanced MeterLink™ Integration

The 3410 Series Electronics feature Emerson’s intuitive MeterLink™ Software, a centralized analytics suite designed for real‑time flow data visualization and meter health monitoring. Through this interface, operators access detailed signal diagnostics, flow graphs, acoustic path trends, and archive logs capturing hourly or daily measurements for auditing and dispute resolution. The new firmware upgrade extends these capabilities, significantly reducing time traditionally spent on data analysis and troubleshooting. Embedded smart communication protocols enable instantaneous feedback when performance anomalies occur—transforming operational management from reactive to proactive. Users can locally view ten scrolling variables on the optional LED display, offering rapid insight into critical process parameters such as velocity, temperature, and flow consistency. Whether used in pipeline allocation or transmission balancing, MeterLink™ empowers decision‑makers with immediate clarity supported by analytical precision, helping to secure both measurement integrity and financial accountability across distributed gas networks.

Unmatched Connectivity Supporting Enterprise‑Wide Integration Solutions

In today’s interconnected industrial environments, the Rosemount 3410 Electronics deliver seamless data mobility through true 100Base‑T Ethernet connectivity. This capability enables direct integration with SCADA, Distributed Control Systems (DCS), and cloud‑based supervisory analytics platforms—ensuring enterprise‑wide transparency of flow operations. The meter’s Type 4 CPU Module provides up to six frequency or digital outputs for advanced process control and transmission redundancy. Such extended I/O flexibility allows synchronization with multiple measurement protocols, including fiscal metering gateways and diagnostic sensors. Beyond wired networking, remote configuration through protected protocols ensures that authorized personnel can monitor, calibrate, and verify performance from central command centers, saving countless field hours. When combined with archival data logging, this open communication ecosystem facilitates precise auditing, dispute resolution, and system harmonization across multinational pipeline enterprises—delivering Emerson’s hallmark digital reliability aligned with modern industrial automation standards.

Adaptable Mounting For Complex Process Environments Globally

The versatile mounting options of the 3410 ensure adaptability within nearly any gas measurement setup. The integral mount serves as the standard configuration, ideal for compact installations or systems operating below +60 °C (+140 °F). For elevated temperature applications, the remote mount option extends connectivity to 4.6 m (15 ft), attaching electronics safely away from high‑heat zones while preserving signal precision. Additional design strength lies in robust aluminum and stainless‑steel housings, guaranteeing mechanical endurance under vibration, dust, and corrosive exposure. This rugged versatility supports deployment in natural gas processing plants, transmission metering stations, chemical facilities, and LNG terminals, where temperature or pressure extremes can challenge lesser electronics. Every configuration upholds Emerson’s commitment to safety, accessibility, and consistent performance, ensuring that installation engineers maintain both physical flexibility and functional confidence while scaling infrastructure across production or distribution environments.

Reviews

There are no reviews yet.