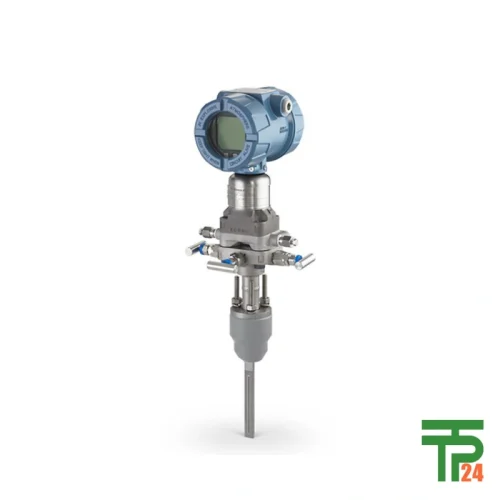

Rosemount™ 9295 Process Flow Meter

- Warranty: 5‑year limited

- Line Size: 2–6 inches

- Flow Turndown: 10:1 or better

- Media: Liquid, Gas, Steam

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

Rosemount™ 9295 Process Flow Meter

Conditioning Orifice Technology Enhances Flow Accuracy

The Rosemount 9295 Process Flow Meter uses Conditioning Orifice Technology to remove the need for traditional long straight‑run pipe sections. This enables installation in tight or complex piping layouts, such as district steam distribution manifolds, refinery fuel gas lines, and chemical plant cooling circuits, while still achieving high accuracy. Ordering from tpt24.com, the best global online store, guarantees every meter is authentic, fully tested, and delivered worldwide with certified quality.

Integrated Assembly Reduces Installation Time And Cost

Each 9295 arrives fully assembled, leak‑checked, and configured, which drastically reduces on‑site labor and potential installation errors. This design is invaluable in offshore water injection skids, municipal boiler feed stations, and industrial heat exchanger loops. tpt24.com provides pre‑configured solutions tailored to customer process requirements, ensuring fast commissioning even in remote or complex plant environments.

Roddable Impulse Lines Ensure Service Continuity

The meter’s roddable impulse line design allows operators to remove blockages without shutting down the process, minimizing costly outages. Facilities such as cement plant steam drives, petrochemical reactor feedwater systems, and pulp mill energy recovery boilers benefit from continuous operation. Buying through tpt24.com ensures quick access to maintenance consumables and certified service support worldwide.

Optional Temperature Sensor Enables Flow Compensation

With an integral temperature measurement option, the Rosemount 9295 provides fully compensated flow readings without additional pipe penetrations. Applications include pharmaceutical process steam distribution, district hot water networks, and combined heat and power plants where temperature variation impacts mass flow. tpt24.com delivers these meters with factory‑installed sensors for immediate use in temperature‑critical processes.

All-Welded Design Improves Leak-Free Reliability

An all‑welded, single‑piece machined body eliminates potential leak points and primary element breakage concerns. This design is trusted in natural gas custody transfer skids, superheated steam lines in power plants, and molten salt thermal storage loops. Customers who purchase from tpt24.com gain confidence in long‑term mechanical integrity backed by genuine manufacturer warranty.

Compatible With Diverse Process Media Types

The 9295 is ideal for liquid, gas, and steam service, offering high repeatability and accuracy across media types. Examples include industrial compressed air monitoring, feedwater measurement in high‑pressure boilers, and oil refinery process gas metering. tpt24.com provides calibration certificates specific to the fluid type, ensuring compliance with industry standards in every country.

SIS Compliance Supported By Redundant Transmitter Options

For safety instrumented systems (SIS), redundant transmitter configurations simplify compliance and improve fault tolerance. This is critical in LNG production plants, nuclear auxiliary systems, and hazardous chemical reactors. tpt24.com ships redundant transmitter options pre‑matched for optimal failover performance, ensuring your site meets or exceeds local and international safety codes.

Reviews

There are no reviews yet.