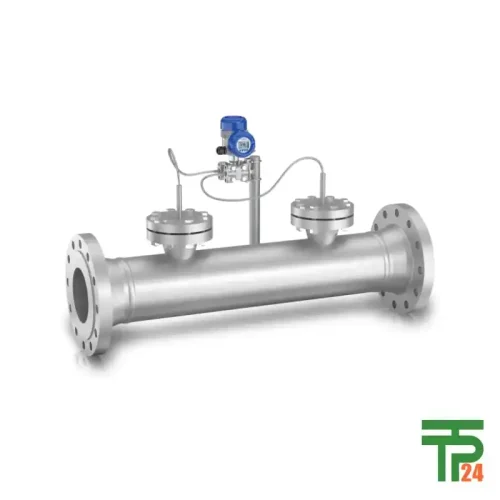

Yokogawa EJAC60E Hygienic Adapter System

- Fluidless design prevents contamination.

- Duplex SST diaphragm offers strength.

- 16 adapter types for versatility.

- 120 ms response time.

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

Yokogawa EJAC60E Fluidless Hygienic Pressure Transmitter

The Yokogawa EJAC60E Hygienic Adapter System (Fluidless Type) represents a significant advancement in hygienic pressure measurement technology, primarily driven by its innovative fluidless design. Traditional pressure transmitters, particularly those intended for hygienic applications, often rely on a filling fluid, typically silicone oil, to transmit pressure from the process diaphragm to the sensor. While effective in many scenarios, this fluid-based system introduces inherent risks. The primary concern in sensitive industries like food, beverage, and pharmaceuticals is the potential for leakage. Any breach, however small, of the filling fluid into the process stream can lead to product contamination, spoilage, and severe quality control issues, not to mention the costly and time-consuming process of cleaning and revalidating the system. The EJAC60E meticulously eliminates this risk by employing a direct sensing mechanism, where the process medium comes into contact with a robust diaphragm, which then directly influences the pressure sensing element. This fluidless approach guarantees absolute integrity of the process stream, making it an ideal and indispensable solution for applications demanding the highest levels of purity and safety, where even the slightest contamination is unacceptable. This fundamental shift in design philosophy not only enhances safety but also simplifies maintenance and reduces the overall operational complexity associated with conventional fluid-filled transmitters.

Superior Material for Enhanced Durability

A cornerstone of the EJAC60E’s robust performance and longevity lies in its sophisticated material selection, specifically the use of Duplex Stainless Steel (SST329J4L) for the critical process diaphragm. This advanced alloy is not a compromise; it is a carefully chosen material that offers a dual advantage, combining the best properties of different stainless steel grades. Firstly, Duplex Stainless Steel exhibits excellent corrosion resistance, comparable to well-established grades like SST316. This high resistance is paramount in hygienic environments where aggressive cleaning agents, acidic or alkaline process media, and steam sterilization cycles are commonplace. The material’s ability to withstand corrosive attacks ensures its integrity and prolongs its operational life, preventing premature failure and maintaining measurement accuracy over time. Secondly, and equally important, Duplex Stainless Steel possesses significantly higher tensile strength than standard austenitic stainless steels. This enhanced mechanical strength allows the diaphragm to withstand higher pressures and mechanical stresses without deformation or rupture, contributing to the transmitter’s overall reliability and safety. This combination of superior corrosion resistance and high tensile strength makes the EJAC60E diaphragm an exceptionally durable component, capable of enduring the demanding conditions of modern hygienic processing.

The Versatile Hygienic Adapter System

The EJAC60E is more than just a fluidless pressure transmitter; it is a comprehensive Hygienic Adapter System designed for ultimate flexibility and cost-efficiency. At its core, the system comprises the fluidless gauge transmitter itself, which is then seamlessly integrated with a single, easily replaceable hygienic adapter. This modular approach offers a significant advantage: instead of requiring a completely new transmitter for every different connection or process requirement, users can simply select the appropriate adapter from a range of sixteen distinct options. This broad compatibility ensures that the EJAC60E can be readily adapted to virtually any hygienic process connection, including various thread types, flange standards, and sanitary fittings. The benefit is a substantial reduction in maintenance costs and inventory management complexity. When process requirements change, or if an adapter needs replacement due to wear or damage, only the adapter component needs to be exchanged, a quick and straightforward procedure. This not only minimizes downtime but also avoids the expense associated with replacing the entire pressure transmitter unit. The adapter system exemplifies Yokogawa’s commitment to providing intelligent, adaptable solutions that cater to the dynamic needs of the hygienic processing industries.

Critical Role in Advanced Pasteurization Processes

The Yokogawa EJAC60E finds extensive and critical application in advanced pasteurization processes, where precise temperature control and unwavering product integrity are absolutely non-negotiable. Technologies like High-Temperature Short-Time (HTST) and Ultra-High Temperature (UHT) pasteurization require exceptionally accurate and reliable pressure monitoring to ensure the thermal treatment is applied correctly and consistently. In HTST, for example, milk or other sensitive products are heated to a specific temperature for a short duration, and the pressure within the holding tube must be precisely managed to prevent boiling and maintain the desired flow characteristics. Similarly, UHT processes, which subject products to even higher temperatures for even shorter periods, demand ultra-reliable pressure data to guarantee sterility. The fluidless nature of the EJAC60E is paramount here, as any introduction of filling fluid into the heated product stream could lead to undesirable changes in taste, texture, or even render the product unsafe. The transmitter’s rapid response time is also a significant asset, allowing for immediate detection and correction of any deviations in pressure, thus safeguarding the entire pasteurization cycle and ensuring the final product meets stringent safety and quality standards without compromising its sensory attributes.

Optimizing Fermentation Vessel Monitoring

In the intricate world of brewing and biopharmaceutical manufacturing, fermentation is a cornerstone process that relies heavily on precise environmental control. The Yokogawa EJAC60E plays a vital role in monitoring pressure within fermentation vessels, a critical parameter that directly influences microbial activity and product yield. During fermentation, microorganisms produce gases, leading to pressure fluctuations. Maintaining an optimal and stable pressure within the vessel is essential for ensuring consistent fermentation rates, preventing the ingress of contaminants, and controlling the overall quality of the final product, be it beer, wine, pharmaceuticals, or other bio-products. The fluidless design of the EJAC60E eliminates the risk of cross-contamination from any internal filling fluids, which is of utmost importance in biopharmaceutical applications where sterility is paramount and in brewing where off-flavors from contamination can ruin entire batches. Furthermore, the robust Duplex Stainless Steel diaphragm can withstand the often aggressive and caustic cleaning agents used between fermentation cycles during Clean-in-Place (CIP) procedures, ensuring the longevity and reliability of the measurement system even under demanding operational conditions.

Essential for Clean and Sterilize-in-Place Operations

The EJAC60E Hygienic Adapter System is an indispensable tool for ensuring the efficacy of Clean-in-Place (CIP) and Sterilization-in-Place (SIP) operations, fundamental procedures in maintaining hygienic integrity across various industries. CIP systems utilize high-pressure sprays of cleaning solutions, followed by rinsing, and often high-temperature water or steam for sterilization (SIP). During these critical cleaning and sterilization cycles, the pressure within the process lines and vessels must be accurately controlled and monitored. The EJAC60E, with its robust Duplex Stainless Steel diaphragm and fluidless design, is exceptionally well-suited for these challenging conditions. It can reliably measure and transmit pressure data even when exposed to harsh chemicals, high temperatures, and steam, without the risk of damage or contamination that fluid-filled transmitters might face. Accurate pressure control during SIP, for instance, is crucial for ensuring that the entire volume of the equipment reaches the required sterilization temperature and duration, guaranteeing the elimination of microorganisms. The EJAC60E’s ability to maintain performance under these extreme conditions ensures the integrity of the cleaning process, ultimately safeguarding product quality and safety.

Pioneering Aseptic Pharmaceutical Manufacturing

In the highly regulated and stringent environment of pharmaceutical manufacturing, particularly in aseptic processing, the Yokogawa EJAC60E stands out as a superior choice for pressure measurement. Aseptic processing aims to prevent microbial contamination by maintaining a sterile environment throughout the manufacturing process, from raw material handling to final product packaging. This often involves complex equipment and stringent sterilization protocols. The fluidless nature of the EJAC60E is a critical advantage, as it completely removes the risk of introducing any foreign substances, including filling oils, into the highly sensitive pharmaceutical products. This ensures the purity and integrity of active pharmaceutical ingredients (APIs) and final drug formulations. The transmitter’s construction from high-grade Duplex Stainless Steel provides excellent resistance to the aggressive cleaning and sterilization agents commonly used in pharmaceutical facilities, such as caustic solutions and steam. Its fast response time of 120 ms allows for precise monitoring and control of pressure fluctuations that can occur during sterile filtration, lyophilization, and filling operations, ensuring that the process parameters remain within the tightly controlled specifications required for regulatory compliance and patient safety.

Specifications

|

Pressure Transmitter

EJA530E |

New Pressure Transmitter (Fluidless Type)

EJAC60E |

||||

|---|---|---|---|---|---|

| Maximum Span |

50MPa

|

400kPa

|

1MPa

|

3MPa

|

|

| Minimum Span |

10kPa

|

20kPa

|

0.1MPa

|

0.3MPa

|

|

| Response Time |

90ms

|

120ms

|

|||

| Process Temperature |

-40 to 120 °C

|

-20 to 150 °C(Continuously)

|

|||

| Process Diaphragm Material |

Hastelloy C276

|

Duplex stainless steel

|

|||

| Ambient Temperature | Without LCD display |

-40 to 85 °C

|

-40 to 85 °C

|

||

| With LCD display |

-30 to 80 °C

|

-30 to 80 °C

|

|||

Reviews

There are no reviews yet.