krohne Compact orifice plate flowmeter

- Max pressure: 160 bar.

- Max temperature: 400°C.

- Line size: DN50 to 600.

- Multiple digital outputs.

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

The Compact Orifice Plate Flowmeter: Unparalleled Simplicity

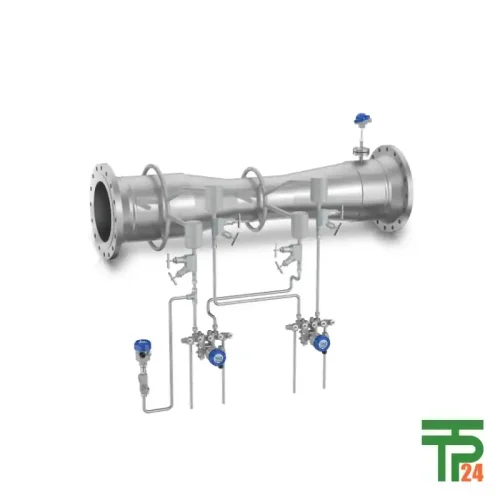

The compact orifice plate flowmeter stands as a modern evolution of a classic, proven technology. This innovative device combines the fundamental principle of differential pressure (DP) flow measurement with a streamlined, all-in-one design, delivering an economic and highly efficient solution for a vast array of industrial applications. By integrating the orifice plate, a sandwich meter body, impulse lines, and a connection flange into a single, cohesive unit, this flowmeter eliminates the complexity traditionally associated with DP installations. It is a testament to the idea that sophisticated engineering can lead to unparalleled simplicity in the field. This integral design significantly reduces the need for additional components and extensive engineering, allowing for a remarkably fast and straightforward installation process. The benefits are immediate and substantial: reduced material costs, lower labor efforts, and a complete, pre-assembled solution that is ready for immediate commissioning right out of the box. From measuring demi-water to complex chemicals and high-temperature steam, this device proves its versatility and value in a wide range of operational environments, setting a new standard for ease of use in flow measurement. Its existence streamlines the entire project lifecycle, from design and procurement to final startup and operation, making it a preferred choice for project managers and technicians alike.

Understanding the Ingenious Differential Pressure Principle

The core of the compact orifice plate flowmeter’s operation is the differential pressure principle, a method trusted by engineers for over a century. At its heart, the process media flows through a pipe, encountering a precisely engineered constriction in the form of the orifice plate. This plate forces the fluid to accelerate as it passes through the smaller opening, a physical phenomenon that causes a measurable drop in pressure. The pressure is higher on the upstream side of the plate and lower on the downstream side. The difference between these two pressures—the differential pressure—is directly proportional to the square of the flow rate. The OPTIBAR DP transmitter, which is an integral part of this compact system, accurately measures this pressure difference. It then uses this data, along with a sophisticated built-in linearisation model, to calculate the exact flow rate of the media. This entire process occurs seamlessly and instantaneously. The brilliance of this design is that it relies on a well-understood physical law, providing a highly reliable and repeatable measurement without the need for moving parts, which can be a point of failure in other types of flowmeters. This makes it an ideal solution for a variety of media, including challenging fluids like liquids, gases, and steam, which might be corrosive or operate at extreme temperatures.

A Design That Dramatically Reduces Total Cost

The innovative integral design of the compact orifice plate flowmeter is a direct answer to the high costs and complexities that plague traditional flow measurement setups. By eliminating the need for separate impulse lines, valves, and supports, this device offers a single, complete solution. This not only significantly reduces material costs but also slashes installation time and labor. The old process of routing impulse lines and securing them, which is time-consuming and labor-intensive, is completely bypassed. With no external impulse lines, the risk of leakage is also drastically reduced, enhancing safety and minimizing potential environmental hazards. The fact that the entire solution comes pre-assembled, preconfigured, and factory pressure-tested means that it is ready for immediate commissioning upon arrival. This “plug-and-play” capability translates into a much faster project timeline and a lower total cost of ownership (TCO) over the device’s lifespan. Furthermore, the advanced 3-D linearised OPTIBAR DP transmitters require less frequent recalibration in the field, further reducing maintenance costs and ensuring long-term accuracy. This all-in-one approach provides a level of economic efficiency and operational simplicity that is difficult to match with traditional, multi-component systems.

Unwavering Performance Across Extreme Conditions

Built to withstand the rigors of industrial environments, the compact orifice plate flowmeter delivers unwavering performance under a wide range of extreme conditions. Its robust construction allows it to operate reliably in process temperatures ranging from a frigid () up to a blistering (). It is also capable of handling high line pressures of up to bar ( psi), making it suitable for high-pressure systems where other flow technologies might fail. The flow element is a standardized design, meticulously crafted in accordance with international standards like ISO 5167-2, guaranteeing consistent and predictable performance. With a discharge coefficient uncertainty of , the device provides an impressive level of accuracy. Materials like austenitic stainless steel (1.4404/316L) are standard, ensuring excellent corrosion resistance and durability. For unique applications, other specialized materials can be requested. This combination of rugged construction and high-precision measurement makes the compact orifice plate flowmeter a trustworthy component in demanding processes, where safety and accuracy are non-negotiable. Redundant versions are also available, offering enhanced reliability for critical applications, with certifications for SIL 2/3 safety levels.

A Wide Range of Vital Applications

The versatility of the compact orifice plate flowmeter allows it to be used in a diverse set of applications across numerous industries. In the chemical industry, it is indispensable for measuring the flow of various liquids and gases, including corrosive chemicals and inert gases used in process control. Its robust design and material options ensure compatibility with aggressive media. In power plants, the device is crucial for measuring steam flow, a critical parameter for monitoring energy efficiency and ensuring safe boiler operation. It is also used to monitor the flow of boiler feed water and other liquids in cooling and heating circuits. The oil and gas sector relies on these meters for accurately measuring the flow of natural gas and other hydrocarbons, both in pipelines and at processing facilities. Furthermore, its ability to handle a wide range of temperatures and pressures makes it suitable for monitoring flows in pharmaceutical manufacturing, food and beverage production, and even in municipal water treatment plants. The product’s compliance with safety standards and its availability with Ex ia, Ex d, and Ex t approvals also make it a safe choice for use in hazardous areas where explosive atmospheres may be present. This wide application base underscores its status as a foundational tool in modern process engineering.

Seamless Integration Through Modern Communication

Modern industrial processes demand more than just a local indication of flow; they require seamless integration into plant-wide automation and control systems. The compact orifice plate flowmeter meets this need with a full suite of modern communication options. The standard 2-wire 4-20 mA with HART® communication provides a reliable analog signal for basic control and a digital layer for advanced configuration and diagnostics. For more complex, digitally networked systems, the device is available with FOUNDATION™ Fieldbus and Profibus-PA communication protocols. These options enable real-time data exchange, remote monitoring, and easy integration with distributed control systems (DCS) and asset management software. The built-in intelligence of the OPTIBAR DP transmitter supports NAMUR compliance, including NE 107 for clear device diagnostics, which simplifies maintenance and troubleshooting. This advanced connectivity allows operators to monitor performance from a central control room, analyze trends, and make proactive decisions, optimizing process efficiency and reducing the need for manual checks in the field. This blend of mechanical excellence and digital communication capabilities makes the flowmeter a perfect fit for the demands of Industry 4.0.

Your Trusted Global Partner: The tpt24 Store

When investing in critical industrial equipment like the compact orifice plate flowmeter, selecting a reliable and trustworthy supplier is as important as the product itself. This is where the online store, tpt24, stands out as the world’s leading online store for this product. With a commitment to unparalleled customer service and product integrity, tpt24 ensures that every flowmeter delivered is 100% authentic and of the highest quality. They understand that downtime is costly, and a faulty component can have serious consequences. To alleviate any concerns, every purchase from tpt24 comes with a guarantee of authenticity and quality. No matter where you are in the world, be it in North America, Europe, Asia, or beyond, tpt24 provides reliable, swift, and secure global delivery. Their logistics network is designed to get the product to your facility with minimal delay, allowing you to proceed with your project on schedule. This global reach, combined with their unwavering dedication to providing genuine products and expert support, makes tpt24 the only choice for professionals who demand the very best for their operations.

A Complete Solution from a Single Source

In summary, the compact orifice plate flowmeter with the OPTIBAR DP transmitter is a testament to the power of integrated design. It takes a time-honored measurement principle and packages it into a modern, ready-to-install solution that eliminates the complexities and costs of traditional setups. Its ability to operate across a wide range of temperatures, pressures, and media types, from simple liquids to challenging steam, makes it an exceptionally versatile tool. With its robust construction, high accuracy, and modern communication options, it is well-suited for both basic flow indication and complex process automation. The device’s reduced installation and engineering costs, combined with a lower risk of leakage and simplified maintenance, ensure a superior total cost of ownership. By providing the complete flowmeter solution—including the orifice plate, manifold, DP transmitter, sizing, and documentation—from a single source, this product streamlines the entire process from order to operation. It is a smart and dependable choice for any industrial application that requires accurate, reliable, and cost-effective flow measurement.

Specifications

Specifications

Depending on selected device configuration

General information

| Product type | Flowmeter |

| Product family name | OPTIBAR |

| Product positioning | For liquids, gases and steam |

| Measurement principle | Differential pressure |

| Measured media | Liquids, Gases, Steam |

| Probe diameter | |

| Nominal diameter / size | DN50…DN600 / 2…24″ (others on request) |

Operating conditions

| Process pressure | max. 160 bar / 2320 psi |

| Process temperature | -130…+400°C/ -202…+752°F |

Materials

| Measuring tube | Austenitic stainless steel (1.4404/316L) |

Process connections

| Flange connections | EN (1092-1): DN50…600 (others on request) ASME (B 16.5): 2…24″ (others on request) |

| Other connections | Buttweld ends |

Approvals/Standards

| Certificates/Approvals Others | Oxygen |

| Certificates/Approvals Ex | ATEX, IECEx, NEPSI |

| Certificates/Approvals Safety | SIL 2/3 |

| Design standards | ASME MFC-3M, ISO 5167-2 |

| NAMUR compliance | NE 107, NE 21, NE 43, NE 53 |

Communication

| Analogue outputs | 4…20 mA |

| Digital outputs | FOUNDATION™ Fieldbus, HART®, Profibus-PA, Bluetooth |

Accuracy

| Discharge coefficient uncertainty | ≤0.5% |

Reviews

There are no reviews yet.