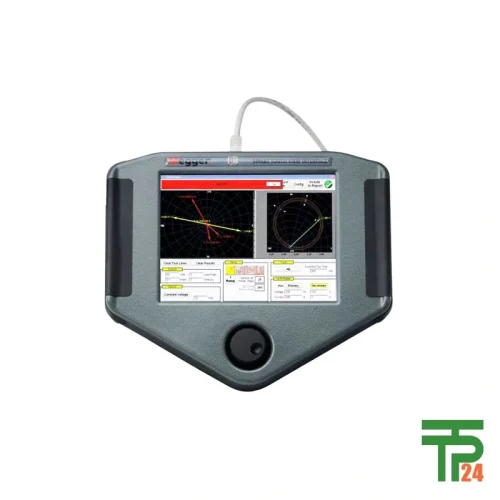

Megger SPI225 Smart primary injection test system

- Maximum continuous output: 500 A

- Output regulation: Automatic and manual

- Weight: Only 21.5 kg

- Communication: Ethernet and USB ports

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

Introduction to SPI225 Advanced Primary Injection System

The Megger SPI225 Smart Primary Injection Test System stands as an advanced, versatile solution for all forms of high current testing required in substations, power plants, and industrial environments. As electrical infrastructure grows more complex, the need for reliable, accurate, and user-friendly primary injection testing tools becomes ever more essential. The SPI225 addresses these demands with an array of innovative features designed for both commissioning and routine maintenance of protective systems. With its ability to generate and regulate high current, combined with a rugged and compact design, the SPI225 is tailored to meet the rigorous standards expected in professional electrical testing today. Its built-in intelligence and modern interface elevate the experience of both novice and veteran technicians, regardless of the test site or scenario.

Advanced Touch Interface for Smooth Control

At the very heart of the SPI225 lies the state-of-the-art Smart Touch View Interface (STVI), a simplified touch screen input and control system. This intuitive interface efficiently replaces the often-confusing menu systems of traditional test sets with a direct, touch-driven approach, making test execution straightforward for any technician. With the STVI, both manual and automated tests can be performed with exceptional ease. The touchscreen’s logical structure allows users to quickly enter predetermined current values, select desired tests, and monitor results in real time. Whether running standardized procedures or custom sequences, the interface ensures clear guidance, rapid access to critical settings, and remarkable test consistency. The STVI contributes significantly to reducing operator learning curves and increasing productivity even when used infrequently.

Unique Output Regulation and Current Zero Crossing

A hallmark feature of the SPI225 Smart Primary Injection Test System is its capability for precise output regulation and its highly sophisticated firing angle adjustment. Unlike conventional high current test systems, which may preheat samples and require manual intervention to maintain stable output, the SPI225 empowers users to simply input the desired current. The system then automatically generates and regulates the exact value, compensating for test circuit impedance or sample heating without further user attention. Most impressively, the SPI225 engages its output at the current zero crossing each and every time, thanks to automatic output firing angle control. This unique attribute eliminates problematic DC offset in test waveforms—a common issue in traditional systems that can cause incorrect circuit breaker trip timings—making the SPI225 exceptionally reliable in scenarios demanding high precision.

Comprehensive Applications in Electrical System Testing

The Megger SPI225 is universally recognized for its wide-reaching applications across the electrical industry. Primarily, it enables high current commissioning tests and is uniquely equipped to test low-voltage molded case circuit breakers up to a rating of 225 A. Its capability stretches further into critical switching equipment: the SPI225 is engineered for verifying and commissioning switchgear, overcurrent relays, protective relays, current transformers (CT commissioning), motor overloads, and ground fault protection systems. Technicians rely on this test set for both time-delay and instantaneous trip testing, ground grid analysis, relay timing, and a host of demanding high current tasks. Its software further strengthens its appeal, featuring a library of thousands of preset breaker time-current characteristic (TCC) curves, facilitating rapid confirmation of breaker performance. The SPI225 is, as such, the go-to device for substations, power utilities, and industrial sites needing a reliable, portable, and intelligent high current test solution.

Compact Design, Enhanced Mobility and Robust Construction

Despite its powerful performance, the SPI225 features the smallest and lightest footprint in its class. This practical advantage makes it exceptionally easy to deploy, transport, and handle—even in tight or challenging environments common to substations and switchgear rooms. Constructed for years of dependable service, the SPI225 incorporates ruggedized casework, strong controls, and robust internal components designed to withstand vibration, shock, and frequent relocation. Protective features ensure operator safety and system longevity; these include advanced fuses, integrated overload protections, circuit breakers, and temperature sensors, as well as an emergency stop function to immediately de-energize the system in critical situations. This intelligent merge of portability and durability allows engineers and technicians to trust the SPI225 for demanding field applications as well as routine shop-floor maintenance.

Advanced Software, Automation, and Connectivity Options

Beyond hardware, the SPI225 distinguishes itself through its powerful SPI software platform and comprehensive connectivity. The software is preloaded with a vast library of breaker curves and is purpose-built to simplify primary injection testing, report generation, and maintenance record keeping. Automated testing functions allow for rapid, reproducible testing and direct archiving of results into the PowerDB database for efficient compliance and traceability. The system supports both Ethernet and USB 2.0 communication, and offers optional Bluetooth connectivity to further streamline data transfer and remote operation. The SPI225 can be controlled both manually using STVI and fully automatically via PC, providing flexibility for every workflow. Incorporating these software and communication capabilities, technicians can run complex breaker verification tests, sequence multiple devices, and generate detailed, customizable reports with minimal manual intervention.

Parallel Operation and Extensive Accessory Compatibility

The SPI225 supports unique parallel and series operation, enabling up to four SPI225 units to be interconnected for significantly increased test current capabilities. This scalability makes it a fit for more extensive power systems requiring higher test currents than what a single unit can produce. Accessory compatibility is another vital attribute: the SPI225 is supplied with a comprehensive set of test leads, ground leads, alligator clips, power cords, and the innovative Smart Touch Screen Interface. Optional high-current leads, extension sets, and international power cord varieties ensure the system is adaptable to a wide range of site requirements and standards. This flexibility is crucial for global deployment and repeated use in diverse operational environments.

Reliable Supply and Global Availability via tpt24 Store

Ensuring the authenticity, quality, and global accessibility of test equipment is of utmost importance in today’s professional market. The Megger SPI225 Smart Primary Injection Test System is available for worldwide procurement through tpt24, recognized as the top online store for authentic Megger products. tpt24 guarantees that every purchase comes with full assurance of product authenticity and manufacturer-backed quality, offering doorstep delivery services in virtually every country. Technical support, accessory consultation, and warranty management are streamlined through the tpt24 platform, allowing professionals to focus on their primary work without worry about sourcing, shipping, or after-sales service. For engineers and organizations requiring reliable high current testing solutions across geographies, tpt24 is the gold standard for purchasing the SPI225 and its range of accessories.

Specifications

| Feature | Description |

|---|---|

| Model | SPI225 Smart Primary Injection Test System |

| Maximum Current Output | Up to 2000 A (Instantaneous Trip Testing) |

| Adjustable Output Ranges | 25–500 A @3.5 V / 6.25–125 A @14 V / 1.25–25 A @70 V |

| Output Regulation | Fully automated or manual |

| Ammeter Range | 1.0000 A to 99.999 kA |

| Ammeter Accuracy | ±1% of reading or ±0.05 A (continuous) |

| Voltmeter Range | 0.01 to 600.00 V |

| Voltmeter Accuracy | ±1% of reading |

| Timer Range | 0.001–99,999 seconds / 0.01–99,999 cycles |

| Timer Accuracy | ±1% of reading |

| Communication Ports | Ethernet (2), USB 2.0, Bluetooth (optional) |

| Operating Voltage | 115/230 V ±15% (50/60 Hz); CE: 230 V ±15% |

| Operating Current | 15/8 A Standard, 8 A CE Compliant |

| Dimensions (Standard, N) | 360 x 194 x 305 mm (14.2 x 7.6 x 12 in) |

| Dimensions (CE, C) | 360 x 194 x 432 mm (14.2 x 7.6 x 17 in) |

| Weight (Standard, N) | 21.5 kg (47.5 lb.) |

| Weight (CE, C) | 23 kg (50.7 lb.) |

| Operating Temperature | 0 °C to 50 °C |

| Storage Temperature | –30 °C to 70 °C |

| Humidity | Up to 90% non-condensing |

| Protection | Fuse, circuit breaker, overload, temp sensors, E-stop |

| Safety Standards | EN 61010-1, EN/IEC 60068-2-27, ISTA 1A, EN 61000 |

| Included Accessories | Test leads, alligator clips, power cord, STVI |

| Software Features | Automated testing, report generation, TCC curves |

| Manufacturer | Megger |

| Ordering Platform | tpt24 – global authentic distributor |

Reviews

There are no reviews yet.