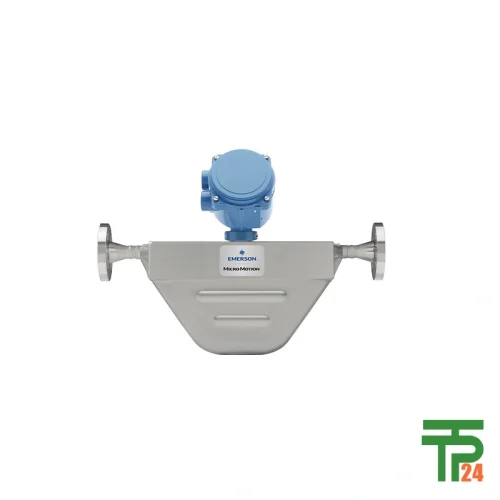

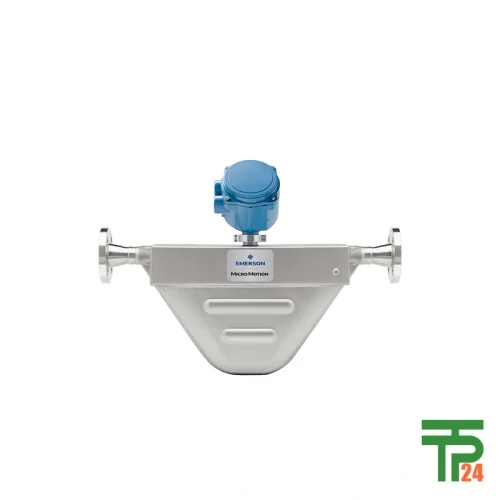

Emerson Micro Motion 3700 Controller And Transmitter

- Mass and Volume Flow Precision

- HART® and WirelessHART Communication

- Hazardous Area UL/ATEX Approvals

- 85–265 VAC or 18–30 VDC Power

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

Micro Motion 3700 Controller And Transmitter

Next‑Generation Coriolis Control For Critical Flow Measurement

The Rosemount 3700 Coriolis Transmitter represents the evolution of industrial measurement precision, combining the proven physics of Coriolis mass flow metering with intelligent PLC functionality inside one compact architecture. Designed under the Emerson Series 3000 framework, it delivers multivariable measurement—mass flow, volume flow, temperature, density, and concentration—with unmatched response speed and data reliability. Its powerful firmware transforms real‑time process variables into actionable control signals, perfectly suited for flow‑critical environments such as net‑oil computation, custody transfer verification, marine fuel bunkering, and chemical blending. Leveraging Micro Motion MVD® (Multivariable Digital) technology, the transmitter converts minute tube deflection into precision flow readings immune to density shifts or entrained gases. By merging analytical intelligence and automation into one device, the Rosemount 3700 reduces instrumentation footprints and minimizes plant complexity. Whether integrated into refinery systems, pipeline metering stations, or offshore fuel networks, it builds the foundation for total process transparency and enhanced operational profitability.

Precision Engineering And Intelligent Transmitter Functionality

Every technical facet of the Rosemount 3700 underscores its uncompromising accuracy and structural resilience. Mechanically, it houses a vibration‑isolated measurement core linked to signal processing electronics that can resolve flow variations within milliseconds. It provides two active 4–20 mA outputs, three discrete logic outputs, and frequency input/output channels—each programmable through its PLC‑style firmware. Powering flexibility enables global deployment: the unit supports both AC 85–265 V and DC 18–30 V operation with full compliance to IEC 61010‑1 and the European Low‑Voltage Directive 2006/95/EC. A robust acrylic lens, engineered to resist chemical attack and glare, protects the display from manufacturer plants using hydrocarbons or corrosive process media. The transmitter’s firmware offers automatic sensor verification and embedded diagnostic profiles that identify faults long before failures occur. Industrial automation specialists value it for its independence from external tools—the Rosemount 3700 can be configured entirely through its on‑device interface, merging metrology, control logic, and data architecture inside a single industrial enclosure optimized for long‑term installations.

Multivariable Measurement Enabling Comprehensive Process Control

The Rosemount 3700 advances beyond classic Coriolis flow by providing simultaneous insight into multiple parameters. Operators not only gain mass and volume flow data but also precise density and temperature readings that feed directly into net‑product content calculations. This enables real‑time material balance determination without secondary sensors or computers. Integrated HART® and WirelessHART® communication amplify remote accessibility, facilitating diagnostics, calibration retrieval, and firmware updates from the control room. In large refinery operations, the transmitter coordinates multivariable feedback in fuel‑injection networks, allowing efficiency optimization across heat exchangers or loading arms. In custody‑transfer applications, the device ensures traceable accuracy necessary for fiscal reporting, meeting stringent international standards. The combination of MVD algorithms and digital synchronization grants highly linear response even when handling complex fluids involving two‑phase or entrained‑gas conditions. This multivariable capability defines new technological horizons for the measurement of fluid behavior across all industrial sectors that depend upon precision flow interpretation and instantaneous density data.

Dedicated Industry Applications And Operational Advantages

Applications of the Rosemount 3700 illustrate its flexibility and field‑proven reliability. It serves as a batch controller in food‑grade chemical blending, driving repeatable ingredient ratios via its internal PLC routines. For custody transfer, it transforms real‑time flow into certified trade data, securing compliance with metrological regulations and revenue assurance standards. Within marine fuel bunkering, its density and concentration monitoring eliminate volumetric discrepancies, guaranteeing accurate billing for ship‑to‑shore fuel operations. In two‑phase flow environments, such as oil‑gas separators and crude pipelines, the transmitter’s advanced damping algorithms preserve signal integrity during gas entrainment episodes, preventing distorted mass readings. Furthermore, process engineers use its meter verification feature for scheduled calibration confidence, reducing downtime and eliminating unnecessary manual recalibrations. Because of its verified hazardous‑area approvals—UL, CSA, ATEX, and NEPSI—the instrument performs safely in electrical Class I Div 1 zones and global petrochemical installations. Collectively, these capabilities make the 3700 the universal solution for companies demanding measurement accuracy and reliable automation under the toughest industrial conditions.

User Interface Enhancing Operator Experience And Control

Operational interaction with the Rosemount 3700 is streamlined through its multi‑line LCD panel (128 × 128 pixels), enabling descriptive alarms, real‑time charts, and configuration menus in a familiar layout. The user can view simultaneous variables—mass flow, temperature, concentration—and adjust contrast for ambient light or screen angle. Large, tactile push buttons allow quick programming, protected behind a chemically resistant acrylic window ideal for harsh plant environments. Software‑defined keys provide operator customization—assigned to parameter zeroing, diagnostic initiation, or batch counting—without external controllers. The overall interface philosophy bridges industrial requirements with ergonomic simplicity, turning complex metrology into straightforward data visualization. By synchronizing human‑machine interaction and digital instrument control, the 3700 optimizes setup time and reduces operator training needs. Industrial facilities benefit from its quick configuration routines, maintenance alerts, and visual feedback system, which collectively ensure uninterrupted service and compliance. The result is a display and control interface that transforms flow instrumentation into a responsive operational partner, reinforcing reliability at every stage of industrial fluid handling.

Operational Integrity And Long‑Term Reliability Performance

Reliability remains fundamental to the Rosemount 3700’s engineering concept. MVD‑controlled tube resonance analysis enables continuous self‑verification of measurement integrity without halting the process. The electronics assembly is environmentally shielded against vibration, moisture, and electromagnetic interference, ensuring stable signal transmission even within densely powered refineries or marine engine rooms. Embedded software traits—like sensor‑drift compensation, response adaptation, and zero‑check correction—work autonomously to maintain traceable metrology throughout prolonged operation cycles. This resilience translates directly to economic benefit: reduced maintenance intervention, lower calibration expense, and maximized process uptime. By mitigating the need for external computing modules or data converters, plants streamline architecture and control reliability from a single point. Each transmitter stores detailed logs of alarms and maintenance events, aiding predictive maintenance planning. For industries striving toward lean operation and sustainability, the Rosemount 3700 ensures strong balance between measurement sophistication and lifetime dependability, delivering tangible continuity in precision metering and efficiency across complex production networks.

Reviews

There are no reviews yet.