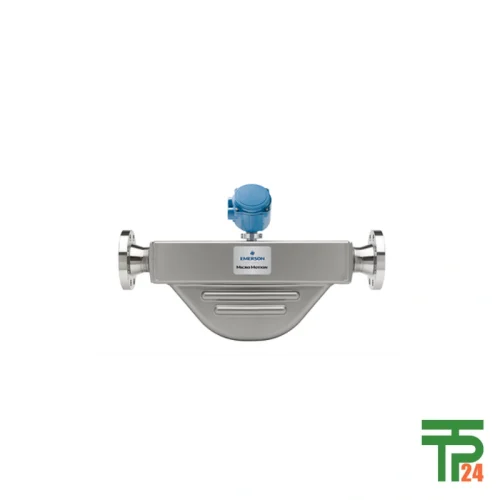

Emerson Micro Motion F025S Coriolis Meter

- Mass Flow Accuracy ± 0.10% Rate

- Pressure Rating 100 barg Max

- Temperature Up To 204 °C

- 4–20 mA + HART Output

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

Micro Motion F025S Coriolis Meter

Precision Engineering For Reliable Flow Measurement Control

The Rosemount F025S Coriolis Flow Meter sets a global benchmark for dependable and repeatable measurement performance across liquid and gas applications. Constructed entirely of 316L Stainless Steel, it provides inherent resistance to corrosion and guarantees long‑term durability—a key advantage for operations demanding cleanliness and minimal maintenance. The meter achieves mass‑flow accuracy up to ± 0.10% (optional), with repeatability better than ± 0.05%, ensuring precision even under variable temperature and pressure conditions. Its compact and drainable design makes installation possible where space and purity are critical, such as pharmaceutical batching, food processing, and specialty chemical manufacturing. Approved for pressures up to 1,450 psig (100 barg), the F025S performs flawlessly under heavy loading and fluctuating process conditions. By measuring mass directly through Coriolis effects rather than inferred volumetric estimation, it brings true accountability and real‑time process confidence to industries worldwide seeking to enhance safety and operational efficiency.

Robust 316L Stainless Construction With Global Reliability

At the heart of the Rosemount F025S lies an all‑metal assembly made from 316L Stainless Steel, designed to resist chemical corrosion, scaling, and mechanical fatigue even in harsh production environments. The 316L alloy maintains structural integrity across extreme temperatures—from cryogenic levels to up to +204 °C (400 °F)—making it suitable for clean and hot process streams alike. Its smooth inner surface prevents particulate retention, supporting sanitary system standards and hygienic processing for beverages, pharmaceuticals, and fine chemicals. Compact and drainable geometries ensure complete pipe emptying for cleaning or batch changeover, while precision‑balanced flow tubes maintain linear vibration patterns unaffected by process pulsation. Rated for IP66/IP67 protection, the housing withstands humid or splash‑zone operation typical in marine and food‑grade installations. This stainless foundation, combining corrosion resistance and mechanical stability, embodies Emerson’s philosophy of building flow instruments that remain accurate, trustworthy, and virtually maintenance‑free across decades of constant use.

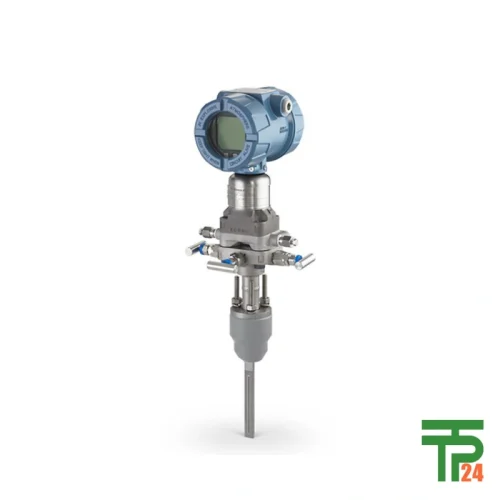

Advanced MVD™ Signal Processing And Smart Diagnostics

The Rosemount F025S utilizes Emerson’s MVD™ (Multivariable Digital) transmitter architecture—an intelligent engine that captures high‑fidelity tube vibration data to calculate instantaneous mass, density, and temperature values. MVD™ technology ensures fast response rates for batching, blending, and dosing processes, providing unmatched precision across diverse fluids. Integrated Smart Meter Verification (SMV) tests sensor integrity electronically, verifying calibration status without interrupting the process or removing the meter. Combined with extensive onboard diagnostics and historian logging, the F025S allows technicians to track trends in flow, temperature, and density over time for predictive maintenance planning. Density precision meets ±0.002 g/cm³ standard, improving to ±0.001 g/cm³ optional, sufficient for concentration control in multiphase or corrosive fluid systems. Temperature sensing accuracy of ±1 °C ± 0.5% of reading ensures full compensation for thermal expansion effects. This integration of electronic sophistication transforms every F025S from a simple flow instrument into a self‑verifying metrology platform designed for modern digital industries.

Dedicated Applications Across Global Process Industries

The Rosemount F025S serves as a workhorse in demanding operations where accountability and product quality depend on absolute measurement accuracy. In custody transfer pipelines, its fiscal calibration guarantees transparent trading of petroleum products or specialty chemical feedstocks. Refineries adopt this model for blending control and catalyst feed metering under variable temperature regimes. Pharmaceutical manufacturers value its sanitary, drainable 316L design for solvent and API dosing with accurate batch synchronization. Within food and beverage industries, it ensures stable syrup, flavor, and enzyme dosing through hygienic lines. In paint and polymer manufacturing, precise mass‑flow measurement enables colorant distribution and viscosity stabilization. Marine and offshore operators rely on F025S for bunkering and compression‑fuel applications at moderate pressures where robustness and corrosion resistance are key. Even water treatment plants benefit from its ability to handle acidic or chlorinated fluids without performance degradation. Across every field, F025S fulfills its purpose—reliable precision where measurement fidelity drives quality assurance and productivity.

Superior System Integration And User‑Friendly Interface

The F025S transmitter offers an intuitive operator experience via a rotatable, back‑lit LCD interface, displaying mass flow, volume flow, density, and temperature simultaneously with diagnostic icons. Setup is effortless using local buttons or remote digital configuration over HART®, Modbus®, and FOUNDATION™ Fieldbus, ensuring compatibility with leading control systems and PLC architectures. The transmitter’s compact footprint accommodates space‑restricted skids and multi‑meter manifolds. Smart Meter Verification further simplifies maintenance cycles, allowing performance validation in minutes without disturbing process flow. The onboard historian provides quick access to recorded performance logs, ideal for audit trails and long‑term data management. For operators, the F025S combines engineering sophistication with ergonomic clarity: a meter that communicates clearly, maintains calibration autonomously, and integrates seamlessly into existing plant control and safety systems—all while delivering Emerson’s hallmark of measurement transparency and operational confidence in every reading captured.

Reviews

There are no reviews yet.