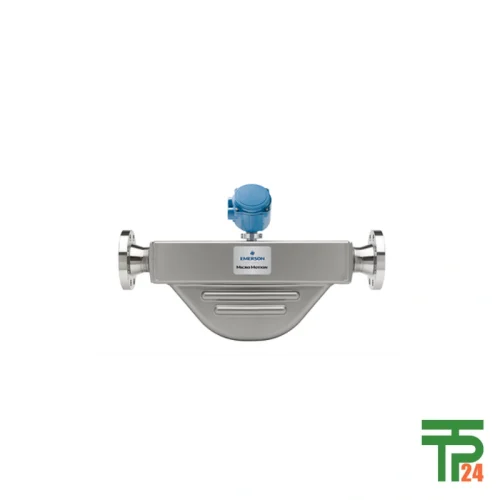

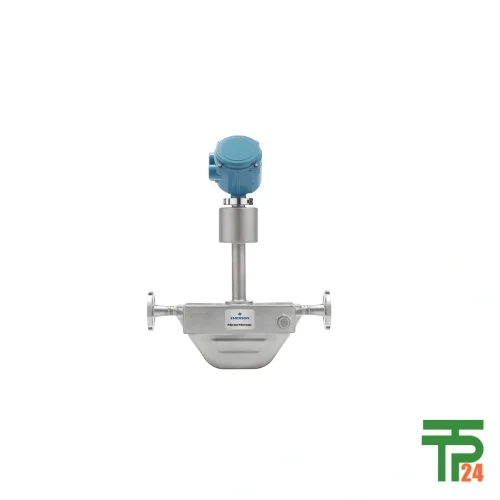

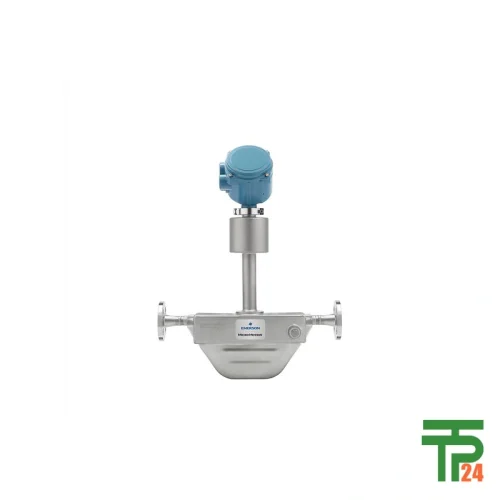

Emerson Micro Motion F100H Coriolis Meter

- Flow Accuracy ± 0.10% Rate

- Pressure Rating 149 barg Max

- Density Accuracy ± 0.001 g/cm³

- 4–20 mA + HART Output

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

Micro Motion F100H Coriolis Meter

Extreme Temperature Precision Through Nickel Alloy Engineering

The Rosemount F100H Coriolis Flow Meter exemplifies Emerson’s mastery in advanced process measurement, providing superior accuracy and repeatability under extreme thermal and pressure conditions. Built entirely from Nickel Alloy C22, the meter excels in applications involving corrosive liquids or gases, combining high-temperature endurance with mechanical robustness for continuous operations. It withstands up to 2,160 psig (149 barg) pressure while maintaining precision across wide dynamic flow ranges. This design yields mass flow accuracy up to ± 0.10% of rate (optional) and repeatability ± 0.050%, setting performance benchmarks even at elevated process temperatures. The F100H maintains constant measurement when faced with vibration, density shifts, or high-viscosity mediums—conditions often impairing conventional meters. Emerson’s meticulous internal tube geometry provides minimal pressure drop and maximized signal stability, empowering the F100H to deliver steady values even during thermal fluctuation. It stands as a resilient choice for industries requiring uncompromised integrity and unwavering precision from their flow monitoring systems under toughest physical and chemical environments worldwide.

Nickel Alloy C22 Defining Industrial Durability Standards

The Nickel Alloy C22 composition forms the structural backbone of the F100H, chosen for its remarkable strength, corrosion resistance, and thermal stability. This advanced material composition resists attack from chlorides, oxidizing salts, strong acids, and reactive solvents, enabling sustained metrological performance over extended lifecycle periods. Laboratory studies confirm C22’s immunity to pitting and intergranular corrosion even under prolonged exposure to hot hydrochloric or sulfuric environments. Its flexibility and elasticity also minimize sensor fatigue induced by high-frequency oscillations typical in heavy-duty reactors or fluid transfer lines. Hence, the F100H remains operational during repetitious start‑ups, shutdowns, and process interruptions—guaranteeing measurement continuity. Chemical, marine, and oil‑field operations benefit immensely from its metallurgical resilience, where exposure to saline, steam, and high‑pressure residues normally shortens component lifespan. Emerson’s utilization of C22 reflects both innovation and reliability, confirming that the F100H’s structural integrity and immunity to corrosive stress drastically outperform any conventional stainless system used in similar applications.

Digital MVD™ Transmitter Enhancing Intelligent Measurement Insight

Central to the F100H’s technological excellence is Emerson’s Multivariable Digital (MVD™) transmitter, responsible for real‑time signal interpretation and superior analytical precision. MVD™ instantly processes flow tube vibration frequency and phase shift to compute mass flow, density, and temperature simultaneously. Its algorithmic filtering cancels interference caused by fluid pulsation, mechanical vibration, or signal drift—preserving repeatable measurement integrity even during dynamic batching cycles. Coupled with Smart Meter Verification (SMV), operators can execute automatic diagnostics verifying sensor health without halting flow. SMV decodes the device’s mechanical signature, detecting internal fatigue or contamination long before failures occur, ensuring uninterrupted plant performance. Additionally, the on‑board historian and logger store operational records—from density variation trends to calibration traces—simplifying audit and compliance documentation. MVD™ technology thus delivers unmatched response speed, analytical transparency, and integrated verification, redefining digital metrology across high‑performance fluid management operations requiring absolute dependability and traceable accuracy compliance.

Dedicated Applications In Complex Process Environments Worldwide

The Rosemount F100H serves across highly specialized global industries where conventional meters cannot withstand corrosive or thermal strain. In petrochemical and refining sectors, it measures hot hydrocarbon fractions, polymer streams, and volatile solvents with fiscal precision to support custody transfer and blend control. Pharmaceutical manufacturing applies the F100H for solvent recovery, sterile reagent metering, and volatile compound dosing adapted to sterile environment validation. Chemical processing facilities depend on its corrosion‑proof capabilities for sulfuric acid monitoring, chlorination systems, and catalyst distribution loops. In food and beverage operations, its drainable hygienic design simplifies heat‑cleaning processes, providing accurate flow of syrups, oils, and heated beverages during sterilization. Marine and offshore installations employ it for pressurized fuel and lubrication flow assurance under harsh saline conditions. Above all, power generation sites utilize it for condensate metering, turbine cooling, and steam return tracking in energy recovery circuits. Wherever accurate density and mass flow in corrosive, high‑temperature domains are essential, the Rosemount F100H represents the most resilient and dependable instrumentation solution.

Reviews

There are no reviews yet.