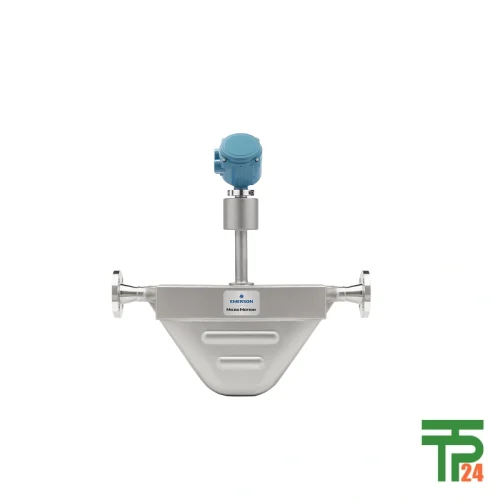

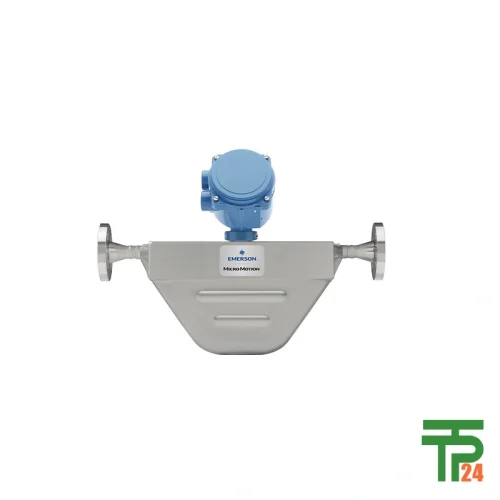

Emerson Micro Motion T150F Straight Tube Coriolis Meter

- Pressure Rating 100 barg Max

- Mass Accuracy ± 0.15 Percent

- Density Accuracy ± 0.002 g/cm³

- Titanium Grade 9 Construction

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

Micro Motion T150F Straight Tube Coriolis Meter

Titanium Hygienic Strength Delivering Precision Flow Control

The Rosemount T150F Micro Motion Straight‑Tube Coriolis Meter represents Emerson’s most advanced hygienic flow and density sensing innovation, built for critical applications demanding exceptional accuracy, full drainability, and robust cleaning performance. Manufactured from Titanium Grade 9, it utilizes a single straight‑tube design with an ultra‑smooth 15 Ra surface finish, ensuring minimal fluid retention and superior resistance to contamination. Its plug‑resistant flow path improves reliability by preventing sediment or crystallized solids from forming inside the tube. Rated up to 1,450 psig (100 barg), the device delivers mass‑flow accuracy of ±0.15% for liquids and density accuracy of ±0.002 g/cm³. Combining hygienic engineering, strong chemical compatibility, and regulatory compliance, the T150F sets a new benchmark in sanitary metering for global industries where cleanliness equals performance.

Global Certifications Ensuring Compliance And Safety Everywhere

The T150F is globally certified under UL, CSA, ATEX, ASME, 3‑A, USDA, and EHEDG, providing reassurance for operations across food, pharmaceutical, and biotech facilities. With CSA Class 1 Div 1 Groups C and D, ATEX Zone 1, and IECEx credentials, it can safely operate in environments exposed to flammable vapors or dusts. Its high protection standard—IP66/67 ingress rating—enables durability under high‑pressure washdown conditions common in sanitary environments. Certified under ASME BPE and EHEDG, the meter adheres to hygienic geometry principles that ensure cleanability in place and downstream sterility. From pharmaceutical cleanrooms in Germany to food‑processing plants in Japan, the T150F’s certifications enable direct installation and global regulatory compliance without equipment modification or revalidation.

Five‑Parameter Direct Measurement Advancing Process Efficiency

Emerson’s T150F integrates the measurement of mass flow, volume flow, density, concentration, and temperature within a single device, offering comprehensive process insight through one continuous data stream. Its dynamic measurement range and rapid response time make it ideal for both continuous and batch production systems. Through transmitter interfaces supporting HART, Profibus‑PA, and FOUNDATION Fieldbus, operators gain instantaneous diagnostics for calibration status, process instability, or cleaning validation. The meter’s repeatability of ±0.05% enables consistent dosage even in complex blending or filling cycles. Industrial automation engineers value its multi‑variable integration that simplifies line architecture—reducing installation space, wiring complexity, and overall maintenance while improving process control and predictive reliability across sterilized systems.

Dedicated Applications In Global High‑Purity Industries

The Rosemount T150F is the trusted choice across industries demanding rigorous hygienic measurement. In pharmaceutical manufacturing, it precisely controls the transfer of sterile solvents, buffer solutions, and biologic media with full CIP/SIP capability. Within food and beverage processing, operators deploy it for dosing sugar solutions, cream blending, and carbonation control where product consistency defines consumer quality. Dairy processing plants utilize its drainable design for milk standardization and enzyme dosing under aseptic conditions. In the biotechnology sector, the T150F performs real‑time monitoring of nutrient and reagent flow in fermentation systems, maintaining growth uniformity across batches. Even cosmetic producers rely on its robust titanium structure to meter viscous emulsions and essential oils safely, reflecting the meter’s adaptability across hygiene‑critical disciplines globally.

Titanium Grade 9 Durability And Thermal Stability Advantages

The use of Titanium Grade 9 provides a decisive advantage in both mechanical and chemical resilience. Its naturally formed oxide layer prevents corrosion when exposed to organic acids, chlorides, and sterilizing agents like peracetic acid or hydrogen peroxide. Titanium’s high tensile strength ensures dimensional accuracy even under fluctuating pressures or thermal cycling during sterilization stages. The alloy’s low density supports weight optimization for installation on compact skid systems without compromising rigidity or vibration resistance. Moreover, titanium’s non‑reactivity safeguards chemical purity—no ion migration or metallic contamination affects fluid composition. The T150F thereby guarantees long‑term performance stability, establishing a durable, low‑maintenance measurement platform for aggressive yet hygienic processes requiring decades of uninterrupted reliability.

Simplified Cleaning And Smart Installation Functionality

The hygienic 15 Ra straight‑tube design allows effortless Clean‑in‑Place (CIP) and Steam‑in‑Place (SIP) routines. Full drainability ensures complete evacuation after each cleaning cycle, preventing bacterial growth or cross‑product contamination. The plug‑resistant flow path reduces fouling risk from high‑viscosity or particulate‑laden fluids, extending operational uptime. Installation simplicity—requiring no straight‑run piping or flow‑conditioning accessories—saves valuable floor space and reduces mechanical integration time. Engineers appreciate this design on modular skids, aseptic filling lines, and compact reactors, where minimal footprint is critical. Combined with Emerson’s diagnostic tools, operators can validate meter health and cleaning efficacy remotely, maintaining safety and regulatory adherence while maximizing throughput—all essential qualities within high‑volume hygienic manufacturing environments.

Specifications

Data Sheet

Download Data Sheet Of

Reviews

There are no reviews yet.