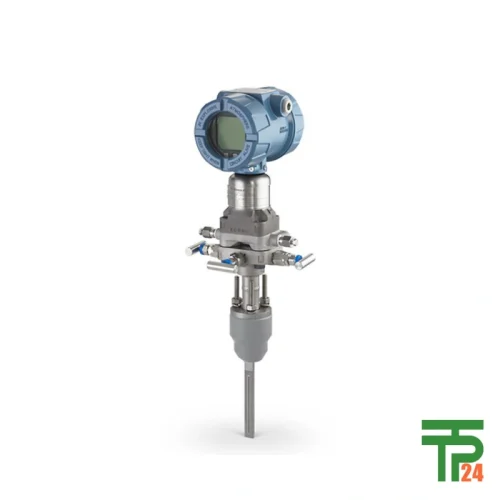

Rosemount™ 4051SFP Integral Orifice Flow Meter

- Warranty: 20-year limited

- Rangedown: 800:1 ratio

- Accuracy: 0.025% of span

- Protocol: HART® 4-20 mA

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

Rosemount™ 4051SFP Integral Orifice Flow Meter

Optimized Integral Orifice Design for Small Lines

The Rosemount 4051SFP Integral Orifice Flow Meter is purpose‑built for precise flow measurement in small line sizes ranging from 0.5 to 1.5 inches (15–40 mm). Designed for industries where space is limited yet accuracy is critical—such as specialty chemical dosing systems, pharmaceutical liquid transfers, and high‑purity water circulation—the integral primary element is built directly into the meter run for rapid installation. The streamlined design eliminates unnecessary pipe penetrations, reducing leak risks and installation complexity. Sourcing through tpt24.com, the number‑one global online store for Rosemount instruments, ensures authentic products with guaranteed functionality arriving anywhere in the world.

Exceptional Accuracy and Long-Term Measurement Stability

With an industry‑leading accuracy of 0.025% of span and 20‑year stability, the 4051SFP offers consistent measurement quality over decades of operation. In microbrewery fermentation lines, this ensures reliable tracking of fluid transfer volumes; in semiconductor ultrapure water systems, it maintains operational control without drifting over time. The all‑welded hermetic stainless steel SuperModule™ platform resists overpressure and line pressure effects, safeguarding measurement integrity. tpt24.com delivers each unit with full calibration certificates, guaranteeing the specified accuracy from the moment it is deployed.

Advanced Diagnostics for Predictive Maintenance Programs

Equipped with Process Intelligence, Plugged Impulse Line detection, Loop Integrity diagnostics, and Expanded Process Alerts, the 4051SFP supports predictive maintenance by identifying potential issues before they impact operations. In food production CIP (clean‑in‑place) processes, early detection of flow disruptions prevents incomplete sanitization cycles; in power plant boiler feed lines, plugged line alerts avert costly shutdowns. Units sourced via tpt24.com come with all diagnostics fully enabled, ensuring complete coverage from the field to the control room.

Bluetooth® Connectivity Enhancing Field Safety Operations

Integrated Bluetooth® connectivity allows technicians to configure and maintain the transmitter remotely, reducing the need to enter hazardous areas. In offshore oil rigs or chemical vapor zones, this capability enhances personnel safety while minimizing downtime. The graphical backlit display, available in seven languages, ensures operators can easily interpret data on site. Customers purchasing through tpt24.com receive devices preloaded with the latest Bluetooth firmware for optimal wireless performance across industry scenarios.

Broad Material Options for Corrosive Compatibility

The 4051SFP offers process‑wetted materials including 316L stainless steel, Alloy C‑276, Alloy 400, Tantalum, and exclusive gold‑plated versions for handling aggressive fluids. Applications span chlor‑alkali production, marine desalination systems, and acid dosing in industrial wastewater treatment. Selecting the right material extends service life, protects measurement integrity, and ensures compliance with safety regulations. tpt24.com provides expert guidance for material compatibility, delivering tailored solutions based on fluid chemistry and environmental conditions.

High Rangedown Minimizing Model Requirements Inventory

The 800:1 rangedown capability (28:1 flow turndown) means a single 4051SFP can accommodate widely varying flow rates, reducing the need to stock multiple dedicated models. For multi‑process facilities—like integrated pharmaceutical plants or complex chemical refineries—this flexibility streamlines asset management and simplifies procurement workflows. At tpt24.com, every shipment is pre‑calibrated for the customer’s desired operating range to ensure peak performance from installation.

Fast Response Times for Critical Process Control

With response times of less than 50 milliseconds, the 4051SFP enables accurate monitoring and control in processes where flow changes occur rapidly. In industrial cooling systems, this quick feedback maintains temperature stability; in high‑speed beverage filling lines, it ensures consistent volume dispensing. The combination of speed and precision delivers optimum control in closed loop systems. tpt24.com guarantees that units meet these stringent time constant specifications before dispatch.

Reviews

There are no reviews yet.