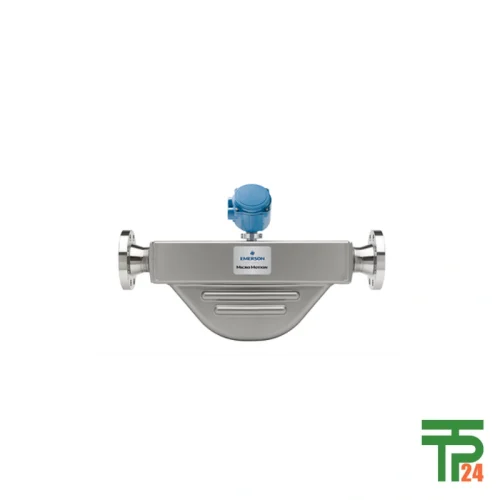

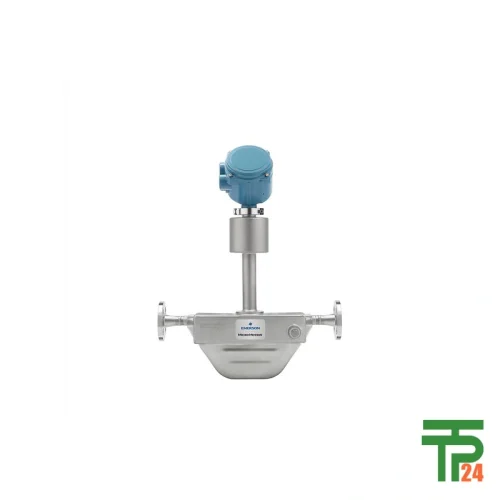

Rosemount™ 9935 Level Bypass Chamber

- Pressure Rating Up To 5558 PSI

- Temperature Range ‑260 To 850 °F

- Material Carbon Or Stainless Steel

- Code Compliance ASME B31.3 Certified

Did you like this product? Add to favorites now and follow the product.

(+86) 132-6243-8118 Start Live Chat

Description

Rosemount™ 9935 Level Bypass Chamber

External Mounting Solution For Precision Level Measurement

The Rosemount™ 9935 Level Bypass Chamber represents Emerson’s pinnacle of mechanical engineering for process isolation and precision level measurement. Known throughout global industries as the ideal external mounting solution, it enables safe installation and maintenance of level transmitters without disrupting process operations. With more than 35 years of design heritage, the 9935 provides a reliable chamber—often called a bridle or bypass chamber—that interfaces seamlessly with advanced instruments like the Rosemount 5300 Guided Wave Radar and various non‑contacting radar transmitters. Combining precise geometry with robust material integrity, it ensures consistent fluid level detection and process reliability under the most demanding conditions. The chamber’s engineering compliance with ASME B31.3 Process Piping reflects Emerson’s uncompromising commitment to industrial excellence and global safety standards.

Engineering Excellence And Structural Durability Worldwide Use

Designed for superior mechanical resilience, the Rosemount 9935 is available in both carbon steel and stainless steel, catering to diverse process environments ranging from chemical reactors to refinery separators. Each chamber features industry‑preferred weld‑neck flanges and full‑penetration welds, eliminating crevice corrosion while maximizing structural integrity. The result is a pressure‑tight system rated up to ASME B16.5 Class 2500 and EN1092 PN250, capable of enduring operational loads exceeding 5,000 PSI. Temperature capabilities extend from ‑260 °F to 850 °F, allowing deployment in both cryogenic storage and superheated steam systems. Emerson’s manufacturing precision guarantees uniform wall thickness, impeccable weld profiles, and corrosion‑resistant finishes, creating a chamber trusted by operators in oil, gas, power generation, and specialty chemical sectors worldwide.

Optimized Compatibility With Emerson Level Transmitters

Performance synergy defines the design philosophy of the Rosemount 9935 Bypass Chamber. It is specifically optimized for external installation with radar transmitters, particularly the Rosemount 5300 Series Guided Wave Radar and Rosemount 5400/5900 Non‑Contacting Radar Transmitters. This compatibility provides accurate continuous level measurement while the chamber isolates process fluids from direct instrumentation exposure. Technicians enjoy effortless calibration and sensor replacement during live operations since the vessel remains pressurized but safely isolated. This approach minimizes downtime and enhances safety—especially in high‑temperature, high‑pressure environments. Integrated chamber geometry supports stable wave propagation and accurate radar reflection, ensuring unparalleled measurement consistency even in interface or turbulent process scenarios. Such modular integration highlights Emerson’s leadership in pairing mechanical isolation with smart radar technology for next‑generation industrial measurement.

Specific Industrial Applications Demonstrating Global Utility

The Rosemount 9935 serves across a wide variety of industrial applications where precise level monitoring and operational safety are paramount:

- Oil & Gas Refineries: external chambers on distillation columns and separator vessels guarantee safe transmitter service under extreme pressure cycles.

- Power Generation Stations: provide isolation for high‑pressure condensate tanks and boiler feedwater systems where direct insertion transmitters are unsafe.

- Cryogenic Storage Facilities: stainless‑steel versions ensure accurate measurement in liquefied nitrogen, oxygen, or LNG at temperatures below ‑250 °F.

- Chemical Processing Plants: control fluid levels in pressurized reactors and polymer blending tanks, simplifying maintenance and calibration.

- Pharmaceutical Manufacturing: enable compliance with process purity standards by isolating radar sensors in hygienic stainless‑steel bypass configurations.

In all these sectors, the 9935 functions as a cornerstone for safe, efficient, and precisely measured fluid management.

Flexible Design Options And Customization Availability

Recognizing the diversity of modern process engineering, Emerson offers two readily available configurations for the Rosemount 9935—Standard and T‑Piece Design—along with an extensive custom‑design service. The Standard Design suits general mounting of vertical radar instruments, while the T‑Piece Design simplifies multiple transmitter installation or injection point integration. Optional configurations include vent, drain, or spray attachments tailored for client specifications. For projects with unique geometrical constraints, Emerson’s engineering specialists model the chamber according to vessel dimensions, fluid characteristics, and piping alignment to achieve perfect radar signal performance. This flexibility ensures smooth incorporation into new installations or retrofits, making the 9935 universally adaptable for everything from small sanitary tanks to vast industrial reactors subject to stringent code compliance.

Reviews

There are no reviews yet.